This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

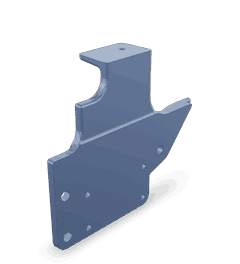

The Cummins 3691442 Tube Brace is a component designed to enhance the structural integrity and performance of heavy-duty trucks. Its role is significant within the context of truck components, providing support and stability to various parts of the vehicle.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce the frame and chassis. They function by distributing loads more evenly across the vehicle’s structure, thereby improving overall stability and durability. In heavy-duty trucks, tube braces contribute to maintaining the integrity of the truck under various operational conditions, including heavy loads and rough terrain 1.

Purpose of the 3691442 Tube Brace

The 3691442 Tube Brace is specifically designed to support the structural framework of a truck. It plays a role in reinforcing the chassis, which helps in withstanding the stresses and strains encountered during operation. By providing additional support, this tube brace contributes to the truck’s durability and performance, ensuring that the vehicle can handle its intended load and operational demands effectively 2.

Key Features

The 3691442 Tube Brace is constructed using high-strength materials, ensuring durability and reliability. Its design includes precise dimensions tailored to fit specific truck models, enhancing its effectiveness. Unique characteristics of this tube brace may include its robust construction and design, which are aimed at providing maximum support with minimal weight addition 3.

Benefits

Utilizing the 3691442 Tube Brace offers several advantages. It enhances the structural stability of the truck, allowing for better load distribution across the chassis. This can lead to improved operational efficiency and safety, as the truck is better equipped to handle its load without compromising structural integrity.

Installation Process

Installing the 3691442 Tube Brace requires careful attention to ensure a secure and effective fit. Preparatory steps include cleaning the installation area and ensuring all necessary tools are available. The installation process involves positioning the brace correctly and securing it in place using the appropriate fasteners. Following manufacturer guidelines is recommended to achieve the best results.

Troubleshooting and Maintenance

Common issues with the 3691442 Tube Brace may include corrosion or damage from impacts. Regular inspections can help identify these problems early. Maintenance practices such as cleaning, checking for signs of wear or damage, and ensuring all fasteners are secure can help prolong the component’s lifespan and maintain optimal performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. Its product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of vehicles.

Role of Part 3691442 Tube Brace in Engine Systems

The 3691442 Tube Brace is a vital component in the structural integrity and efficient operation of various engine systems. It provides robust support and stability to key components, ensuring optimal performance and longevity.

Integration with Fluid Doser

In systems incorporating a Fluid Doser, the 3691442 Tube Brace plays a significant role. The Fluid Doser is responsible for precise fluid injection into the engine, which is vital for maintaining combustion efficiency and reducing emissions. The Tube Brace secures the Fluid Doser in place, minimizing vibrations and ensuring that the doser operates within specified parameters. This stability is particularly important during high-performance scenarios where engine vibrations can be pronounced.

Enhancing System Reliability

By reinforcing the connections between the Fluid Doser and other components, the 3691442 Tube Brace contributes to the overall reliability of the engine system. It helps in maintaining the alignment of the Fluid Doser, which is crucial for consistent fluid delivery. This alignment ensures that the doser can accurately meter the fluid, leading to improved engine performance and reduced wear on other components.

Supporting Structural Integrity

The Tube Brace also supports the structural integrity of the engine bay. It acts as a bridge between various components, distributing loads and stresses more evenly. This reduces the risk of component failure due to excessive stress or fatigue. In high-stress environments, such as racing or heavy-duty applications, the Tube Brace’s role becomes even more pronounced, helping to maintain the engine’s structural soundness under extreme conditions.

Facilitating Maintenance and Repairs

From a maintenance perspective, the 3691442 Tube Brace simplifies access to the Fluid Doser and other connected components. Its presence ensures that these components remain in their intended positions, making it easier for mechanics to perform inspections, adjustments, and repairs. This can lead to reduced downtime and more efficient maintenance procedures.

Conclusion

The 3691442 Tube Brace is a vital component that enhances the performance, reliability, and maintainability of engine systems, particularly those utilizing a Fluid Doser. Its role in providing structural support and stability cannot be overstated, making it an indispensable part of modern engine designs.

-

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.