This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

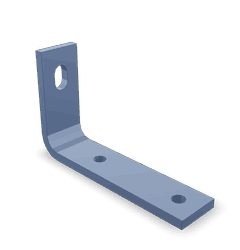

The 3866163 Tube Brace, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems aimed at enhancing the performance and reliability of trucks. This Cummins part plays a role in the structural integrity of trucks by providing additional support and stability. Tube braces are integral to vehicle construction, contributing to the overall framework and ensuring that trucks can withstand various operational stresses 1.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce the chassis and frame. They function by distributing loads more evenly across the vehicle’s structure, thereby enhancing its overall stability and durability. In the context of trucks, tube braces help in maintaining the integrity of the frame under heavy loads and during rough driving conditions. They are typically installed at strategic points where additional support is needed, contributing to the vehicle’s ability to handle stress and strain 1.

Purpose of the 3866163 Tube Brace

This part is designed to enhance the structural integrity and durability of trucks. By providing additional support to the chassis, it helps in distributing loads more effectively, which can lead to improved performance and longevity of the truck. This tube brace is particularly beneficial in scenarios where trucks are subjected to heavy loads or operate in challenging environments, as it helps in maintaining the structural stability of the vehicle.

Key Features

The 3866163 Tube Brace is characterized by its robust material composition and precise design specifications. It is crafted from high-quality materials to ensure durability and resistance to wear and tear. The design of the brace is tailored to fit specific points on the truck’s chassis, providing optimal support where it is needed most. Additionally, the brace may feature unique attributes such as corrosion-resistant coatings or specialized mounting brackets, which differentiate it from other tube braces on the market.

Benefits

Utilizing the 3866163 Tube Brace offers several advantages. It contributes to improved structural stability by reinforcing the chassis, which can lead to enhanced load-bearing capacity. This, in turn, may result in increased operational efficiency and safety, as the truck is better equipped to handle heavy loads and challenging conditions. The brace also plays a role in prolonging the lifespan of the truck by reducing stress on the chassis, thereby minimizing the risk of structural damage.

Installation Process

Installing the 3866163 Tube Brace requires careful attention to detail to ensure optimal performance and longevity. The process begins with preparing the installation site, which involves cleaning and inspecting the chassis to ensure it is free from debris and damage. The necessary tools, such as wrenches and torque wrenches, should be gathered beforehand. During installation, it is important to follow the manufacturer’s guidelines regarding torque specifications and alignment to ensure the brace is securely and correctly fitted. Regular inspections post-installation can help in identifying any issues early on and ensuring the brace remains effective.

Troubleshooting and Maintenance

Common issues with tube braces may include corrosion, misalignment, or damage due to impacts. Regular inspections are recommended to identify these problems early. Maintenance practices such as cleaning the brace and its mounting points, checking for signs of wear or corrosion, and ensuring all fasteners are tight can help in prolonging the life of the 3866163 Tube Brace. If any damage is detected, it is advisable to address it promptly to prevent further deterioration and ensure the continued structural integrity of the truck.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted source in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, reliability, and efficiency of trucks. Cummins’ reputation for quality and innovation makes it a preferred choice for truck components, including the 3866163 Tube Brace.

Compatibility with Cummins Engines

The Tube Brace part 3866163, manufactured by Cummins, is a critical component designed to provide structural support and stability to the engine’s framework. This part is engineered to fit seamlessly within the engine architecture of various Cummins models, ensuring optimal performance and longevity.

Compatibility with Specific Engine Models

- 6B5.9 and QSB5.9 CM850 Engines

The Tube Brace part 3866163 is specifically designed to integrate with the 6B5.9 and QSB5.9 CM850 engines. These engines, known for their robust design and reliability, benefit from the added support provided by this part. The Tube Brace ensures that the engine’s internal components remain securely positioned, reducing the risk of mechanical failure and enhancing overall engine durability.

- QSB6.7 M CM2250 Engine

Similarly, the QSB6.7 M CM2250 engine is another model that is compatible with the Tube Brace part 3866163. This engine, which is part of the Cummins QSB series, is widely used in various industrial and commercial applications. The Tube Brace plays a crucial role in maintaining the structural integrity of the engine, providing essential support to the engine’s framework and ensuring that it operates efficiently under demanding conditions.

Importance of the Tube Brace in Engine Performance

The Tube Brace part 3866163 is an integral component that contributes to the overall stability and performance of the engine. By providing a secure mounting point for various engine parts, it helps to minimize vibrations and mechanical stress, which can lead to premature wear and tear. This, in turn, enhances the engine’s lifespan and ensures that it continues to operate at peak performance levels.

Installation and Maintenance

Proper installation of the Tube Brace part 3866163 is essential to ensure that it functions effectively. Technicians should follow the manufacturer’s guidelines and use the appropriate tools and techniques to secure the brace in place. Regular maintenance checks should also be conducted to ensure that the Tube Brace remains in good condition and continues to provide the necessary support to the engine.

Role of Part 3866163 Tube Brace in Various Engine Systems

Gear Systems

In gear systems, the Tube Brace (part 3866163) is instrumental in maintaining the structural integrity of the gear assembly. It provides additional support to the gear housing, ensuring that the gears remain aligned and operate smoothly under varying loads. This support is particularly important in high-torque applications where the gear housing may experience significant stress. The Tube Brace helps in distributing the load more evenly, reducing the risk of gear misalignment and subsequent wear.

Marine Engines

For marine engines, the Tube Brace plays a significant role in stabilizing the engine components against the dynamic forces encountered in a marine environment. It is often used to reinforce the mounting points of the engine to the hull or engine bed. This reinforcement is essential for maintaining the alignment of critical components such as the crankshaft and camshaft, especially during rough sea conditions. The Tube Brace helps in minimizing vibrations and ensuring that the engine operates efficiently and reliably over extended periods.

Turbocharger Location

At the turbocharger location, the Tube Brace is used to secure the turbocharger to the engine block or exhaust manifold. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions. The Tube Brace helps in maintaining the precise alignment of the turbocharger, which is essential for optimal airflow and efficient turbocharging. It also aids in managing the thermal expansion that occurs during operation, ensuring that the turbocharger remains securely fastened without compromising its performance 2.

Conclusion

The 3866163 Tube Brace is a vital component in the structural integrity and performance of commercial trucks and various engine systems. Its role in distributing loads, enhancing stability, and prolonging the lifespan of trucks and engines is significant. Proper installation and maintenance of this part are crucial to ensure its effectiveness and the overall reliability of the vehicle or engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.