This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3910451 Tube Brace by Cummins is a component designed to enhance the structural integrity of commercial trucks. Its purpose is to provide additional support to the truck frame, ensuring stability and durability under various operating conditions.

Basic Concepts of Tube Braces

A tube brace is a structural component used in vehicle construction to reinforce the frame. It typically consists of a tubular section that is welded or bolted into place to provide additional strength and rigidity. Tube braces contribute to the overall stability and durability of the truck by distributing loads more effectively and reducing the risk of frame deformation or failure 1.

Purpose of the 3910451 Tube Brace

The 3910451 Tube Brace plays a specific role in the operation and structural support of a truck. It is designed to enhance the rigidity and load-bearing capacity of the truck frame. By providing additional support, this tube brace helps to maintain the structural integrity of the truck, especially under heavy loads or in demanding operating conditions 2.

Key Features

The 3910451 Tube Brace features a robust material composition, typically high-strength steel, which ensures durability and resistance to wear and tear. Its design specifications include precise dimensions and welding points to ensure a secure fit within the truck frame. Unique attributes of this tube brace may include corrosion-resistant coatings and optimized placement for maximum effectiveness 3.

Benefits of Using the 3910451 Tube Brace

Incorporating the 3910451 Tube Brace into truck construction offers several advantages. These include improved durability of the truck frame, enhanced safety by reducing the risk of structural failure, and increased load capacity, allowing the truck to carry heavier payloads without compromising stability 4.

Installation Process

Proper installation of the 3910451 Tube Brace involves several steps. First, the truck frame must be thoroughly inspected to ensure it is free of damage or corrosion. The tube brace should then be positioned according to the manufacturer’s specifications, using appropriate tools and equipment. Welding or bolting the brace into place requires precision to ensure a secure and lasting connection. Safety precautions, such as wearing protective gear and ensuring the work area is clear of obstacles, are imperative during installation.

Maintenance and Troubleshooting

To ensure optimal performance and longevity of the 3910451 Tube Brace, regular maintenance is recommended. This includes inspecting the brace for signs of wear, corrosion, or damage. Common issues may involve loose connections or minor deformations, which can often be addressed by re-tightening bolts or making minor adjustments. In cases of significant damage, professional repair or replacement may be necessary.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its high-quality engines and components. Founded in 1919, Cummins has a long history of innovation and excellence, offering a wide range of products designed to enhance the performance and reliability of commercial vehicles. The company’s reputation for quality and durability is reflected in its extensive product lineup, which includes engines, powertrain components, and aftermarket parts.

Role of Part 3910451 Tube Brace in Engine Systems

The 3910451 Tube Brace is an integral component in the structural integrity and efficient operation of various engine systems. Its primary function is to provide robust support and stability to key components, ensuring optimal performance and longevity.

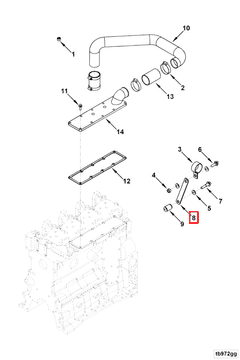

Air Crossover Connection

In systems featuring an air crossover connection, the 3910451 Tube Brace plays a significant role. It secures the air crossover pipe, which is responsible for distributing air evenly between the turbochargers in a twin-turbo setup. This even distribution is essential for balanced airflow, which directly impacts the engine’s power output and efficiency. The brace ensures that the air crossover connection remains firmly in place, minimizing vibrations and potential leaks that could otherwise degrade performance.

Turbocharger Arrangement

When dealing with turbocharger arrangements, particularly in multi-turbo configurations, the 3910451 Tube Brace is employed to maintain the precise alignment of turbochargers. Proper turbocharger arrangement is vital for synchronized operation, which enhances turbo response and reduces the risk of turbo lag. The brace helps in keeping the turbochargers securely positioned, allowing for consistent and reliable performance across a wide range of engine speeds.

Turbocharger Location

The location of turbochargers within an engine bay can be challenging due to space constraints and the need for efficient heat management. The 3910451 Tube Brace addresses these challenges by providing a stable mounting solution for turbochargers. It ensures that turbochargers are held in their optimal positions, facilitating better airflow management and reducing the likelihood of heat-related issues. This stability is particularly important in high-performance engines where turbochargers operate under extreme conditions.

Conclusion

In summary, the 3910451 Tube Brace is a key component in enhancing the structural integrity and operational efficiency of engine systems. Its role in supporting the air crossover connection, maintaining turbocharger arrangement, and securing turbocharger location underscores its importance in achieving peak engine performance.

-

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.