This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

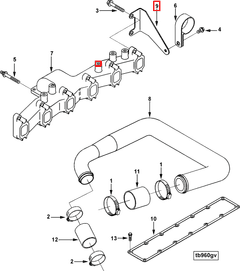

The Cummins 3911233 Tube Brace is a component designed for heavy-duty truck applications. Its purpose is to enhance the structural integrity of the vehicle, ensuring durability and reliability under demanding conditions. This tube brace is significant in maintaining the overall performance and safety of heavy-duty trucks.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce frames and chassis. They function by distributing stress and load more evenly across the vehicle’s structure, which helps prevent deformation and failure under heavy loads or harsh conditions. Tube braces contribute to the overall integrity of the vehicle by providing additional support to critical areas, thereby enhancing stability and safety 1.

Purpose of the 3911233 Tube Brace

The Cummins 3911233 Tube Brace plays a specific role in the operation and structural integrity of heavy-duty trucks. It supports other components by reinforcing the frame and chassis, which are subject to significant stress during operation. This reinforcement helps maintain the alignment and integrity of the truck’s structure, enhancing its durability and longevity 2.

Key Features

The Cummins 3911233 Tube Brace is characterized by several key features. It is constructed from high-strength materials, ensuring it can withstand the rigors of heavy-duty use. The design includes precise dimensions and fittings to ensure a secure and effective installation. Unique attributes of this tube brace may include corrosion-resistant coatings and optimized geometry to maximize strength and durability 3.

Benefits of Using the 3911233 Tube Brace

Incorporating the Cummins 3911233 Tube Brace into truck designs offers several advantages. It improves structural rigidity, which is vital for maintaining the truck’s performance under load. Enhanced safety is another benefit, as the brace helps prevent structural failures that could lead to accidents. Additionally, the increased longevity of the vehicle is a significant advantage, as the brace contributes to the overall durability of the truck’s frame and chassis 4.

Installation Process

Proper installation of the Cummins 3911233 Tube Brace involves several steps. Preparatory steps include ensuring the truck’s frame is clean and free of debris. The necessary tools for installation may include wrenches, torque wrenches, and alignment tools. Best practices for installation include following the manufacturer’s guidelines for torque specifications and ensuring all connections are secure and aligned correctly to achieve optimal performance 5.

Troubleshooting Common Issues

Common problems that may arise with the Cummins 3911233 Tube Brace include corrosion, fatigue, or improper installation. Corrosion can be addressed through regular inspections and the application of protective coatings. Fatigue may be mitigated by ensuring the brace is installed correctly and by monitoring the truck’s usage patterns. Improper installation can often be corrected by re-evaluating the installation process and making necessary adjustments to ensure all components are secure and aligned 6.

Maintenance Recommendations

Regular maintenance of the Cummins 3911233 Tube Brace is important to ensure continued performance and longevity. Inspection intervals should be established to check for signs of wear, corrosion, or damage. Cleaning procedures may include washing the brace with a mild detergent and water, followed by the application of a protective coating if necessary. Replacement should be considered if significant damage or wear is detected during inspections 7.

Cummins Corporation Overview

Cummins Inc. is a well-established corporation with a rich history in the automotive and heavy-duty truck industry. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins is renowned for its commitment to quality, innovation, and customer satisfaction, making it a trusted name in the industry 8.

Role of Part 3911233 Tube Brace in Engine Systems

The 3911233 Tube Brace is an essential component in the structural integrity and performance optimization of various engine systems. Its primary function is to provide additional support and stability to key components, ensuring efficient operation and longevity.

Turbocharger Arrangement

In turbocharged engine setups, the 3911233 Tube Brace plays a significant role by reinforcing the arrangement of the turbocharger. This reinforcement helps maintain the precise positioning of the turbocharger, which is vital for optimal airflow and performance. The brace minimizes vibrations and potential movement that could otherwise lead to inefficiencies or damage 9.

Turbocharger Location

When it comes to the turbocharger location, the 3911233 Tube Brace ensures that the turbocharger remains securely in place. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions. The brace helps distribute the stresses and loads more evenly, reducing the risk of component failure and enhancing the overall reliability of the engine system 10.

Conclusion

By integrating the 3911233 Tube Brace into these engine components, engineers and mechanics can achieve a more robust and efficient engine setup, capable of withstanding the demands of high-performance applications.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for G8.3 CM558 G105, Bulletin Number 4332678.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for G8.3 CM558 G105, Bulletin Number 4332678.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.