This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

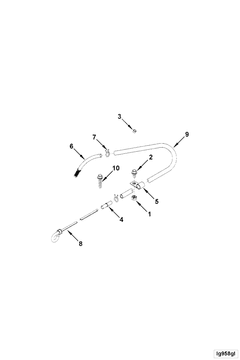

The Cummins 3914730 Tube Brace is a component designed to enhance the structural integrity of commercial trucks. It serves a specific function within the truck’s frame, contributing to overall stability and durability under various operational conditions.

Basic Concepts of Tube Braces

A tube brace is a structural element used in the framing of vehicles to provide additional support and rigidity. It typically consists of a tubular section that is strategically positioned and welded to the main frame members. The brace works by distributing loads more evenly across the frame, reducing the stress on individual components and enhancing the frame’s overall resistance to deformation 1.

Purpose of the Cummins 3914730 Tube Brace

The Cummins 3914730 Tube Brace is designed to reinforce the frame of commercial trucks. It plays a role in the structural stability by providing additional support where the frame may be subjected to high stress. This reinforcement helps in maintaining the frame’s integrity, especially under heavy loads or in rough terrain, thereby contributing to the longevity and safety of the vehicle 2.

Key Features

The Cummins 3914730 Tube Brace is constructed from high-strength steel, ensuring durability and resistance to wear and tear. Its design specifications include precise dimensions and welding points that are engineered to integrate seamlessly with the truck’s frame. Unique attributes of this tube brace may include its specific shape and placement, which are optimized for the particular stress patterns of the trucks it is designed for.

Benefits of Using the Cummins 3914730 Tube Brace

Installing the Cummins 3914730 Tube Brace offers several advantages. It contributes to improved durability of the truck’s frame, enhances safety by reducing the risk of frame failure under stress, and may potentially increase the truck’s load-carrying capacity by providing additional structural support.

Installation Considerations

Proper installation of the Cummins 3914730 Tube Brace is important for ensuring its effectiveness. Guidelines recommend that the frame be thoroughly inspected for any existing damage or wear before installation. The brace should be securely welded at the designated points to ensure it functions as intended. It is also advisable to follow manufacturer recommendations for any preparatory steps, such as cleaning the welding area to ensure a strong bond.

Troubleshooting and Maintenance

Common issues with tube braces may include weld failure or damage to the brace itself due to impacts or corrosion. Regular inspections can help identify these problems early. Maintenance practices should include checking the integrity of the welds and the condition of the brace, and addressing any issues promptly to ensure the continued performance and longevity of the component.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation in truck components. With a history of developing reliable and high-performance parts, Cummins has built a reputation for excellence in the field of commercial vehicle manufacturing and component supply.

Cummins Tube Brace 3914730: Application Across Engine Models

The Cummins Tube Brace part number 3914730 is a critical component in the structural integrity of several Cummins engine models. This part is designed to provide support and stability to the engine’s internal components, ensuring that the engine operates smoothly and efficiently.

Application in Cummins 4B3.9 Engines

In the Cummins 4B3.9 engine, the Tube Brace 3914730 plays a pivotal role in maintaining the alignment and positioning of various engine parts. This particular engine model is known for its robust design and reliability, often used in heavy-duty applications where durability is paramount. The Tube Brace ensures that the engine’s internal components remain securely in place, reducing the risk of misalignment and potential damage.

Application in Cummins 6BT5.9 Engines

Similarly, in the Cummins 6BT5.9 engine, the Tube Brace 3914730 is integral to the engine’s structural framework. This engine model is widely used in a variety of applications, from industrial machinery to transportation vehicles. The Tube Brace helps to maintain the integrity of the engine’s components, ensuring that the engine can withstand the rigors of continuous operation.

Application in Cummins ISB6.7 Engines

The Cummins ISB6.7 engine also benefits from the Tube Brace 3914730. This engine is known for its high performance and efficiency, making it a popular choice in both commercial and industrial settings. The Tube Brace provides essential support to the engine’s components, helping to maintain the engine’s structural integrity and performance over time.

Application in Cummins QSK60 Engines

In the Cummins QSK60 engine, the Tube Brace 3914730 is a key component that ensures the engine’s components remain properly aligned. This engine model is designed for heavy-duty applications, where it must operate under extreme conditions. The Tube Brace helps to maintain the engine’s structural integrity, ensuring that it can perform reliably even in the most demanding environments.

Application in Cummins L10 Engines

The Cummins L10 engine also utilizes the Tube Brace 3914730 to maintain the alignment and stability of its internal components. This engine model is known for its durability and reliability, making it a popular choice in a variety of applications. The Tube Brace ensures that the engine’s components remain securely in place, reducing the risk of damage and extending the engine’s lifespan.

By providing essential support and stability to the engine’s components, the Cummins Tube Brace 3914730 is a critical part in ensuring the performance and longevity of various Cummins engine models.

Role of Part 3914730 Tube Brace in Engine Systems

The 3914730 Tube Brace is an essential component in maintaining the structural integrity and operational efficiency of engine systems. It provides robust support to various engine components, ensuring they remain securely in place under the dynamic conditions of engine operation.

Integration with Gauge Systems

In gauge systems, the 3914730 Tube Brace plays a significant role by stabilizing the mounting points for gauges. This ensures that the gauges remain firmly attached and do not shift or vibrate excessively during engine operation. Stable gauge mounting is vital for accurate readings and reliable performance. The brace helps in distributing the forces exerted on the gauge, reducing the risk of damage or misalignment.

Support for Oil Level Sensors

For oil level sensors, the 3914730 Tube Brace offers necessary support by securing the sensor housing and associated tubing. This is particularly important in high-vibration environments where the sensor must remain stationary to provide consistent and accurate oil level readings. The brace helps in minimizing movement and potential wear on the sensor components, thereby enhancing the longevity and reliability of the oil level monitoring system.

By effectively supporting these components, the 3914730 Tube Brace contributes to the overall stability and performance of the engine system, ensuring that critical measurements and readings are maintained with precision.

Conclusion

The Cummins 3914730 Tube Brace is a vital component for enhancing the structural integrity and operational efficiency of commercial trucks and various Cummins engine models. Its role in providing additional support and stability to the frame and engine components ensures the longevity, safety, and performance of the vehicle under demanding conditions. Proper installation and maintenance of this part are crucial for maximizing its benefits and ensuring the continued reliability of the truck or engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.