This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

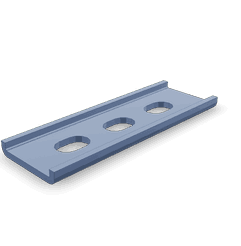

The Cummins 3918785 Tube Brace is a component designed for heavy-duty truck applications. Its purpose is to enhance the structural integrity and performance of trucks under demanding conditions. This part is significant in maintaining the durability and reliability of heavy-duty vehicles, ensuring they can withstand the rigors of their intended use.

Basic Concepts of Tube Braces

A tube brace is a structural component used in vehicle frameworks to provide additional support and rigidity. It typically consists of a tubular section that connects two or more points within a vehicle’s chassis. The primary function of a tube brace is to distribute loads more evenly across the structure, reducing stress on individual components and enhancing overall vehicle integrity 1.

Purpose of the Cummins 3918785 Tube Brace

The Cummins 3918785 Tube Brace plays a specific role in the operation and structural integrity of a truck. It is designed to reinforce the chassis, particularly in areas that experience high stress or torsional loads. By doing so, it contributes to the truck’s durability and performance, allowing it to handle heavier loads and operate in more challenging environments without compromising safety or efficiency 2.

Key Features

The Cummins 3918785 Tube Brace is characterized by several key features that set it apart from other tube braces. It is constructed from high-strength materials, ensuring durability and resistance to wear and tear. The design includes precise engineering to fit seamlessly within the truck’s chassis, providing optimal support without adding unnecessary weight. Additionally, it may feature unique attributes such as corrosion-resistant coatings or specialized mounting points to enhance its functionality and longevity 3.

Benefits

Using the Cummins 3918785 Tube Brace offers several benefits. It improves structural rigidity, which can lead to enhanced safety by reducing the risk of chassis failure under load. Additionally, it may increase the truck’s load-carrying capacity, allowing it to transport heavier payloads without compromising structural integrity. The brace also contributes to the overall performance and longevity of the vehicle by mitigating stress on the chassis 4.

Installation Process

Installing the Cummins 3918785 Tube Brace requires careful attention to detail to ensure optimal performance. The process begins with preparing the chassis by cleaning the installation area and ensuring all mounting points are accessible. The necessary tools, such as wrenches and torque wrenches, should be gathered beforehand. The brace is then positioned according to the manufacturer’s instructions, secured in place using the provided hardware, and torqued to the specified settings to ensure a secure fit. It is important to follow best practices, such as double-checking all connections and ensuring the brace is aligned correctly, to maximize its effectiveness.

Troubleshooting and Maintenance

Common issues with tube braces may include corrosion, loosening of hardware, or damage from impacts. Regular inspections can help identify these problems early, allowing for timely repairs or replacements. Maintenance practices such as cleaning the brace and its mounting points, checking for signs of wear or corrosion, and ensuring all hardware is tight can prolong the lifespan of the Cummins 3918785 Tube Brace. Additionally, addressing any chassis modifications or repairs promptly can prevent further complications.

Compatibility and Applications

The Cummins 3918785 Tube Brace is designed for use in specific types of trucks and models. It is commonly applied in heavy-duty truck applications where enhanced structural support is required. Notable applications may include long-haul trucking, construction vehicles, and other heavy-duty transport scenarios where durability and load-carrying capacity are paramount.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry. With a history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance components. The company’s commitment to excellence is evident in its rigorous manufacturing processes and continuous investment in research and development, ensuring that its products meet the demanding needs of the industry.

Tube Brace Part 3918785 Compatibility with Cummins Engines

The Tube Brace part number 3918785, manufactured by Cummins, is designed to fit a variety of Cummins engine models. This part is crucial for maintaining the structural integrity of the engine by securing and supporting the tubing within the engine compartment. Below is a detailed breakdown of the compatibility of this tube brace with various Cummins engines:

4B3.9 and 6B5.9 Engines

The Tube Brace part 3918785 is compatible with both the 4B3.9 and 6B5.9 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The tube brace ensures that the tubing within these engines remains properly aligned and secured, preventing any potential movement or damage that could affect engine performance.

6C8.3 and L9.3 Engines

Similarly, the Tube Brace part 3918785 is also suitable for the 6C8.3 and L9.3 engines. These engines are part of Cummins’ lineup of high-performance diesel engines, frequently utilized in various industrial and commercial applications. The tube brace plays a vital role in maintaining the structural stability of the engine’s tubing, ensuring that it can withstand the rigors of continuous operation.

L105 and QSC8.3 CM554 Engines

The Tube Brace part 3918785 is also designed to fit the L105 and QSC8.3 CM554 engines. These engines are known for their durability and efficiency, making them popular choices in a range of applications from construction to marine use. The tube brace ensures that the tubing within these engines is properly supported, contributing to the overall longevity and reliability of the engine.

By ensuring that the tubing within these engines is properly secured, the Tube Brace part 3918785 helps maintain the structural integrity and performance of the engine, making it an essential component for these Cummins engine models.

Role of Part 3918785 Tube Brace in Engine Systems

The part 3918785 Tube Brace is an essential component in the structural integrity and performance optimization of various engine systems. It is strategically positioned to support and reinforce key elements, ensuring efficient operation and durability.

Support for the Camshaft

In engine systems, the camshaft plays a pivotal role in controlling the timing of the valve operation. The Tube Brace provides additional support to the camshaft, reducing vibrations and ensuring smooth operation. This support is particularly important in high-performance engines where camshafts are subjected to greater stress and higher rotational speeds.

Stability for the Fuel Manifold and Fuel Plumbing

The fuel manifold and fuel plumbing are responsible for distributing fuel to the injectors. The Tube Brace enhances the stability of these components, minimizing the risk of fuel line displacement or damage. This is vital for maintaining consistent fuel delivery and preventing leaks, which can compromise engine performance and safety.

Reinforcement for Injector and Injector Fuel Supply Tube

Injectors are precision components that deliver fuel into the combustion chamber. The Injector Fuel Supply Tube connects the fuel manifold to the injectors. The Tube Brace reinforces these components, ensuring they remain securely in place. This reinforcement is essential for maintaining the precise fuel delivery required for optimal engine performance.

Integrity of Injector Plumbing

The Injector Plumbing consists of various hoses and fittings that transport fuel from the fuel manifold to the injectors. The Tube Brace provides additional support to these components, reducing the likelihood of hose disconnections or fittings loosening. This ensures a reliable fuel supply and contributes to the overall efficiency of the engine.

Integration with On Board Spares and Performance Parts

In systems equipped with On Board Spares and Performance Parts, the Tube Brace plays a role in maintaining the structural integrity of these additional components. Whether it’s an extra fuel filter or high-performance injectors, the Tube Brace ensures that these parts remain securely mounted, contributing to the reliability and performance of the engine.

Role in Performance Parts Kits

Many performance parts kits include components designed to enhance engine power and efficiency. The Tube Brace is often included in these kits to provide the necessary support for the upgraded components. This ensures that the performance gains are not compromised by structural weaknesses.

Conclusion

In summary, the part 3918785 Tube Brace is a key component in enhancing the durability and performance of various engine systems. Its role in supporting and reinforcing critical components ensures that the engine operates efficiently and reliably under a wide range of conditions.

-

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing, 2011

↩ -

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ -

Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, Robert Bosch GmbH, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.