This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Understanding The Cummins 3919296 Tube Brace In Commercial Trucks

Introduction

Commercial trucks are the backbone of logistics and transportation, making the reliability of their components paramount. Among these critical parts is the Cummins 3919296 Tube Brace, a seemingly small but vital element in the engine system. Understanding its role, maintenance, and the impact it has on truck performance is essential for ensuring the longevity and efficiency of commercial vehicles 1.

Basic Concepts Related To Tube Braces

A Tube Brace is a structural component designed to reinforce and stabilize various parts of an engine. In the context of truck engines, Tube Braces play a crucial role in maintaining the structural integrity of the engine block and other components. They help distribute stress and vibrations, ensuring that the engine operates smoothly and efficiently. Without proper bracing, engines can suffer from increased wear, reduced performance, and even catastrophic failure 2.

Purpose Of The Cummins 3919296 Tube Brace

The Cummins 3919296 Tube Brace is specifically engineered to support the engine block and other critical components in Cummins engines. Its primary role is to provide additional strength and stability, which contributes to the overall efficiency and durability of the truck. By reinforcing the engine structure, the Tube Brace helps to mitigate the effects of high stress and vibration, ensuring that the engine operates within optimal parameters 3.

Importance Of The Cummins 3919296 Tube Brace In Truck Operations

The Cummins 3919296 Tube Brace is indispensable in supporting the engine and maintaining its performance. A malfunctioning or damaged Tube Brace can lead to significant issues, including increased engine wear, reduced efficiency, and potential safety hazards. Real-world examples have shown that Tube Brace failures can result in engine misalignment, increased vibration, and even engine failure, highlighting the need for regular inspections and maintenance 1.

Troubleshooting The Cummins 3919296 Tube Brace

Common issues with the Cummins 3919296 Tube Brace include signs of wear, corrosion, and physical damage. Mechanics should look for cracks, deformations, and any signs of loosening or detachment. A step-by-step troubleshooting guide involves visual inspection, checking for proper alignment, and ensuring that all mounting points are secure. Regular inspections and maintenance are crucial to identifying and addressing potential problems before they lead to more severe issues 2.

Maintenance Tips For The Cummins 3919296 Tube Brace

To ensure the longevity and performance of the Cummins 3919296 Tube Brace, it is essential to follow best maintenance practices. This includes regular inspections for signs of wear or damage, ensuring that all mounting points are tight and secure, and addressing any issues promptly. A recommended maintenance schedule involves checking the Tube Brace during routine engine inspections and more thorough checks during major service intervals. Additionally, keeping the engine clean and free of debris can help prevent corrosion and extend the life of the Tube Brace 3.

Cummins: A Leader In Truck Engine Parts

Cummins is renowned for its commitment to quality and innovation in truck engine parts. The company’s dedication to producing reliable and high-performance components makes Cummins parts a preferred choice for commercial truck operators. Choosing Cummins parts, including the 3919296 Tube Brace, ensures that trucks are equipped with the best available technology and craftsmanship 1.

Expert Insights And Best Practices

Industry experts emphasize the critical role of Tube Braces in maintaining engine performance and safety. Best practices for engineers and mechanics include thorough inspections, prompt repairs, and adherence to recommended maintenance schedules. Fleet operators are encouraged to ensure that their Tube Braces are in optimal condition to avoid downtime and ensure the safety and efficiency of their vehicles 2.

Case Studies And Real-World Applications

Case studies of successful Tube Brace installations and maintenance highlight the importance of this component. Real-world applications demonstrate scenarios where the Tube Brace has proven critical in preventing engine failure and maintaining performance. Lessons learned from industry professionals underscore the value of regular maintenance and the importance of using high-quality parts 3.

Cummins Tube Brace 3919296 Compatibility

The Cummins Tube Brace part number 3919296 is designed to fit seamlessly with several engine models, ensuring structural integrity and optimal performance. This part is specifically engineered to provide robust support within the engine compartment, catering to the unique needs of various engine configurations.

Engine Compatibility

- 4B3.9 and B4.5 Engines

The Tube Brace 3919296 is compatible with both the 4B3.9 and B4.5 engines. These engines, known for their reliability and efficiency, benefit from the added support provided by this part. The brace helps maintain the alignment and stability of critical engine components, contributing to the overall durability and longevity of the engine.

- B4.5 RGT Engine

Similarly, the B4.5 RGT engine also integrates well with the Tube Brace 3919296. This variant, which may include additional features or modifications, still relies on the structural support offered by the brace. The part’s design ensures that it fits snugly and securely, providing the necessary reinforcement to withstand the rigors of engine operation.

Installation and Functionality

While the specific installation details for the Tube Brace 3919296 will be covered in a larger article, it is important to note that this part is meticulously crafted to fit the specified engine models. Its primary function is to provide a stable framework that helps distribute mechanical stresses evenly, preventing potential damage to the engine and its components.

By ensuring that the Tube Brace is correctly installed, technicians and owners can maintain the integrity of the engine assembly, leading to improved performance and reduced maintenance needs.

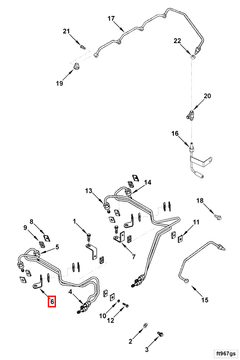

Role of Part 3919296 Tube Brace in Engine Systems

The 3919296 Tube Brace is an essential component in the structural integrity and efficient operation of various engine systems. It provides necessary support and stability to several key components, ensuring optimal performance and safety.

Fuel Plumbing System

In the fuel plumbing system, the 3919296 Tube Brace secures and stabilizes the fuel lines. This support is vital for maintaining the integrity of the fuel delivery system, preventing leaks and ensuring consistent fuel flow to the engine. The brace helps in absorbing vibrations and reducing the stress on the fuel lines, which can otherwise lead to wear and potential failure.

Fuel Pump Plumbing

For the fuel pump plumbing, the 3919296 Tube Brace plays a significant role in securing the connections between the fuel pump and the fuel lines. This ensures that the fuel pump operates efficiently without undue strain on its plumbing. The brace helps in maintaining the alignment and stability of the fuel pump components, contributing to reliable fuel delivery under various operating conditions.

Injector Fuel Supply Tube

The 3919296 Tube Brace is also instrumental in supporting the injector fuel supply tube. By providing a stable mounting point, it ensures that the fuel supply tube remains securely in place. This is important for maintaining precise fuel injection timing and volume, which are critical for engine performance and efficiency.

Injector Plumbing

In the context of injector plumbing, the 3919296 Tube Brace helps in securing the injector lines and connections. This support is essential for preventing leaks and ensuring that the injectors receive a consistent supply of fuel. The brace also aids in managing the thermal expansion and contraction of the plumbing components, thereby enhancing the durability and reliability of the injector system.

General Plumbing Support

Beyond specific components, the 3919296 Tube Brace offers general support to various plumbing elements within the engine system. Whether it’s fuel lines, return lines, or other fluid pathways, the brace ensures that these components are held firmly in place. This reduces the risk of disconnections, leaks, and other issues that can arise from unsecured plumbing.

Fuel and Injector Systems Integration

The 3919296 Tube Brace facilitates the integration of fuel and injector systems by providing a common mounting point for multiple components. This integration is key to maintaining a cohesive and efficient fuel delivery system, ensuring that both fuel supply and injection processes work seamlessly together.

Conclusion

The Cummins 3919296 Tube Brace is a vital component in the engine system of commercial trucks. Its role in providing structural support and stability cannot be overstated. Regular maintenance, prompt troubleshooting, and the use of high-quality parts are essential for ensuring the longevity and performance of commercial vehicles. Continued education and awareness of critical truck parts like the Tube Brace are encouraged to maintain the highest standards of safety and efficiency in the industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.