This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3921417 Tube Brace is a component designed to enhance the structural integrity of commercial trucks. Its purpose is to provide additional support and stability to the truck’s frame, ensuring it can withstand the rigors of heavy-duty use.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce frames and chassis. They contribute to the overall stability and durability of a truck by distributing loads more effectively and reducing the risk of frame flex or failure under stress 1.

Purpose of the 3921417 Tube Brace

This Cummins part plays a specific role in the operation and structural support of a truck. It is positioned within the truck’s frame to provide additional reinforcement. This brace helps in maintaining the frame’s rigidity, ensuring that the truck can handle heavy loads and rough terrains without compromising structural integrity.

Key Features

The 3921417 is characterized by its robust design and material composition. Constructed from high-strength steel, it offers excellent durability and resistance to wear and tear. Its dimensions are tailored to fit precisely within the truck’s frame, ensuring optimal performance and longevity. Unique attributes such as corrosion-resistant coatings further enhance its durability in various operating conditions 2.

Benefits of Using the 3921417 Tube Brace

Incorporating this part into a truck’s frame provides several advantages. It improves load distribution across the frame, enhances overall rigidity, and increases resistance to stress and fatigue. These benefits contribute to a more reliable and durable truck, capable of performing under demanding conditions.

Installation Considerations

Proper installation of the 3921417 Tube Brace is vital for its effectiveness. Guidelines recommend thorough preparation of the installation site, ensuring the frame is clean and free of debris. The use of appropriate tools and careful alignment are crucial to achieve the desired structural reinforcement. Following manufacturer instructions ensures the brace is installed correctly, maximizing its benefits 3.

Troubleshooting Common Issues

Tube braces, including the 3921417, may encounter issues such as corrosion, misalignment, or structural fatigue. Regular inspections can help identify these problems early. Solutions may involve cleaning and reapplying protective coatings to combat corrosion, realigning the brace to correct misalignment, or assessing the need for replacement in cases of significant fatigue.

Maintenance Recommendations

Routine maintenance of the 3921417 Tube Brace involves regular inspections to check for signs of wear, corrosion, or damage. Cleaning the brace and applying protective coatings as needed can prolong its lifespan. Replacement or repair should be considered if significant degradation is observed, ensuring the truck’s structural integrity is maintained.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial vehicle, engine, and power systems markets. The company is renowned for its commitment to producing reliable and high-performance components, including the 3921417 Tube Brace, which reflects its dedication to enhancing the durability and efficiency of commercial trucks.

Role of Part 3921417 Tube Brace in Engine Systems

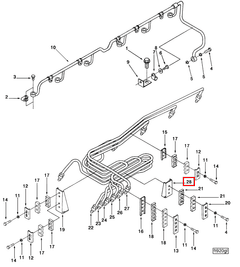

The 3921417 Tube Brace is a component in maintaining the structural integrity and efficient operation of various engine systems. Its primary function is to provide support and stability to the injector fuel supply tube, ensuring that it remains securely in place during engine operation.

Support for Injector Fuel Supply Tube

The injector fuel supply tube is responsible for delivering fuel from the fuel tank to the injectors. This part plays a significant role in this system by preventing the tube from shifting or vibrating excessively. This stability is vital for maintaining consistent fuel delivery, which directly impacts engine performance and fuel efficiency.

Integration with Plumbing Systems

In the context of engine plumbing, the Tube Brace helps to secure the fuel lines and other related components. By doing so, it reduces the risk of fuel leaks and ensures that the plumbing system operates smoothly. This is particularly important in high-performance engines where vibrations and thermal expansion can pose challenges to the integrity of fuel lines.

Fuel System Stability

The fuel system in an engine is a complex network of components that work together to deliver the right amount of fuel at the right time. The 3921417 Tube Brace contributes to the overall stability of this system by providing a solid mounting point for the fuel supply tube. This ensures that the fuel system can withstand the dynamic conditions within the engine compartment, such as temperature fluctuations and mechanical stress.

Enhanced Performance and Reliability

By securing the injector fuel supply tube and supporting the fuel plumbing, the 3921417 Tube Brace indirectly enhances the performance and reliability of the engine. Consistent fuel delivery leads to more efficient combustion, which can result in better engine performance and reduced emissions. Additionally, the reduced risk of fuel leaks contributes to safer and more reliable engine operation.

Conclusion

The 3921417 Tube Brace is a vital component for both the structural integrity of commercial trucks and the efficient operation of engine systems. Its robust design, coupled with strategic placement within the truck’s frame and engine systems, ensures enhanced durability, performance, and reliability. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall effectiveness and longevity of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.