This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

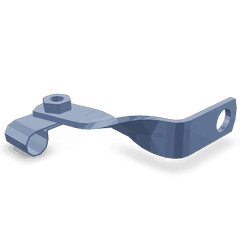

The Tube Brace 3924989, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part is specifically engineered to enhance the structural integrity of trucks, playing a role in their overall performance and durability.

Basic Concepts of Tube Braces

A tube brace is a structural component used in vehicle frameworks to provide additional support and rigidity. It typically consists of a metal tube that is strategically positioned and secured to the chassis. The primary function of a tube brace is to reinforce the vehicle’s structure, helping it to better withstand the stresses and vibrations encountered during operation. By doing so, tube braces contribute to the overall integrity and performance of a truck, ensuring it can handle the demands of heavy-duty use 1.

Purpose of Tube Brace 3924989

The Tube Brace 3924989 is designed to enhance the structural stability of a truck’s chassis. It plays a role in distributing stress more evenly across the chassis, which can help to prevent deformation and maintain alignment under load. This brace is particularly beneficial in mitigating the effects of vibrations and impacts, which are common in commercial trucking operations. By reinforcing the chassis, the Tube Brace 3924989 contributes to the truck’s ability to maintain structural integrity over time 2.

Key Features

The Tube Brace 3924989 is constructed from high-strength steel, which provides durability and resistance to wear. Its design specifications include precise dimensions and secure mounting points to ensure it integrates seamlessly with the truck’s chassis. One unique attribute of this tube brace is its engineered shape, which is optimized to provide maximum support with minimal weight addition. This design consideration is crucial for maintaining the truck’s performance without unnecessary weight penalties 3.

Benefits

Utilizing the Tube Brace 3924989 offers several advantages. It contributes to improved durability by reinforcing the chassis, which can lead to a longer service life for the truck. Enhanced safety is another benefit, as a stronger chassis is better equipped to handle the stresses of heavy-duty operations. Additionally, the increased structural integrity may allow for higher payload capacities, translating to operational efficiencies for fleet operators by maximizing cargo capacity within safety limits.

Installation Considerations

When installing the Tube Brace 3924989, it is important to follow guidelines and best practices to ensure optimal performance and longevity. Proper alignment is crucial, as incorrect positioning can lead to ineffective bracing and potential chassis damage. Securing methods should be robust to withstand the dynamic forces experienced during truck operation. Careful attention to these details during installation will help to maximize the benefits of the tube brace.

Troubleshooting and Maintenance

Common issues with tube braces can include corrosion, physical damage from impacts, or loosening of securing bolts. Regular inspections can help identify these issues early, allowing for timely repairs or replacements. Maintenance tips for prolonging the life of the Tube Brace 3924989 include keeping it clean and free from debris, checking for signs of wear or damage, and ensuring that all securing methods remain tight and effective. Adhering to recommended service intervals for inspection and maintenance will help to ensure the continued reliability of the tube brace.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction make it a trusted source for automotive components, including the Tube Brace 3924989.

Compatibility with Cummins Engines

This part is designed to provide structural support and stability to various Cummins engine models. It is integral in maintaining the integrity of the engine’s framework, ensuring optimal performance and longevity.

Compatible Engines

- 6B5.9

- B5.9 G

- B5.9 GAS PLUS CM556

- ISB CM550

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

Grouping of Compatible Engines

The Tube Brace 3924989 is compatible with a range of Cummins engines, including both the B5.9 and ISB series. The B5.9 series includes the 6B5.9, B5.9 G, and B5.9 GAS PLUS CM556 engines. These engines are known for their robust design and are often used in various industrial applications.

The ISB CM550 engine is part of the ISB series, which is renowned for its reliability and efficiency. This engine is commonly used in heavy-duty applications, including construction and agricultural equipment.

The QSB series, which includes the QSB5.9 30 CM550, QSB5.9 44 CM550, and QSB6.7 CM850 (CM2850), is designed for high-performance and durability. These engines are frequently used in demanding environments, such as marine and power generation.

Lastly, the QSB7 CM2880 B117 engine is a high-output variant of the QSB series, providing exceptional power and efficiency for specialized applications.

By ensuring that the Tube Brace 3924989 is correctly installed, users can maintain the structural integrity of these engines, contributing to their overall performance and lifespan.

Role of Tube Brace 3924989 in Engine Systems

The Tube Brace 3924989 is an essential component in maintaining the structural integrity and operational efficiency of various engine systems. It plays a significant role in supporting and securing the oil level gauge, which is vital for monitoring the oil levels within the engine.

Supporting the Oil Level Gauge

The oil level gauge is a critical instrument used to measure the amount of oil present in the engine. Accurate oil level readings are essential for ensuring that the engine operates within safe parameters, preventing both oil starvation and overfilling. The Tube Brace provides the necessary support to keep the oil level gauge securely in place, ensuring that it remains operational and accurate throughout the engine’s operation.

Ensuring Gauge Stability

In dynamic engine environments, vibrations and movements can affect the stability of components. The Tube Brace mitigates these effects by providing a stable mounting point for the oil level gauge. This stability is important for the gauge’s accuracy, as any movement or shifting can lead to incorrect readings, potentially resulting in improper engine maintenance decisions.

Integration with Oil Systems

Beyond just supporting the oil level gauge, the Tube Brace also plays a role in the overall integration of the oil system components. It helps in maintaining the alignment and positioning of the gauge relative to other oil system parts, such as the oil pump and oil filter. This alignment is important for the efficient flow of oil and the accurate measurement of oil levels.

Enhancing System Reliability

By securely holding the oil level gauge in place, the Tube Brace contributes to the reliability of the entire oil monitoring system. This reliability is important for the long-term performance and durability of the engine, as consistent and accurate oil level readings help in timely maintenance and prevent potential engine damage due to oil-related issues.

Conclusion

In summary, the Tube Brace 3924989 is a key component in the engine’s oil monitoring system, providing essential support and stability to the oil level gauge, and contributing to the overall reliability and efficiency of the engine. Its role in reinforcing the chassis and supporting critical engine components underscores its importance in maintaining the performance and longevity of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.