This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

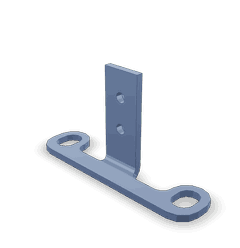

The Cummins 3925301 Tube Brace is a component designed for heavy-duty truck applications. Its purpose is to enhance the structural integrity of the vehicle, ensuring stability and durability under demanding conditions. This part plays a role in supporting various components within the truck’s framework.

Purpose and Function

The Tube Brace contributes to the structural integrity of heavy-duty trucks by providing additional support to critical components. It helps distribute loads more evenly across the vehicle’s frame, reducing stress on individual parts. This support enhances the overall stability and longevity of the truck, making it more reliable for heavy-duty operations 1.

Design and Construction

The Cummins 3925301 Tube Brace is manufactured using high-quality materials and advanced processes to ensure durability and performance. The design incorporates robust construction techniques, such as precision welding and reinforced joints, to enhance its strength. These elements are important for withstanding the rigors of heavy-duty use 2.

Key Features

The primary features of the Tube Brace include its robust construction, which is engineered to handle significant loads. Its precise design ensures compatibility with specific truck models, providing a secure fit. These features contribute to the brace’s effectiveness in enhancing vehicle performance and reliability.

Benefits

Using the Cummins 3925301 Tube Brace offers several advantages. It improves load distribution across the truck’s frame, which can lead to enhanced safety and increased durability. These benefits translate to better overall performance and reliability for truck operators, making it a valuable component for heavy-duty applications 3.

Installation Process

Proper installation of the Tube Brace involves several steps to ensure a secure and effective fit. Begin by identifying the correct mounting points on the truck’s frame. Use the provided hardware to attach the brace, ensuring all connections are tight and secure. Follow the manufacturer’s guidelines for torque specifications to maintain structural integrity.

Maintenance and Care

Regular maintenance and inspection of the Tube Brace are important for ensuring its continued performance. Check for signs of wear or damage, such as cracks or corrosion, and address any issues promptly. Timely repairs or replacements can prevent more significant problems and maintain the brace’s effectiveness.

Troubleshooting Common Issues

Common problems with the Tube Brace may include loose connections or signs of wear. To address these issues, first, ensure all mounting points are secure and tightened to the specified torque. If wear is detected, assess the extent of the damage and replace the brace if necessary. Regular inspections can help identify and resolve these issues early.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has a long history of providing reliable solutions for heavy-duty applications. Their focus on engineering excellence ensures that components like the 3925301 Tube Brace meet the high standards required for demanding environments 4.

Compatibility with Cummins Engines

The Tube Brace part number 3925301, manufactured by Cummins, is designed to provide structural support and stability to specific engine models. This part is integral in maintaining the integrity of the engine’s framework, ensuring that the engine components remain securely in place during operation.

Cummins 4B3.9 Engine

In the Cummins 4B3.9 engine, the Tube Brace part 3925301 plays a role in supporting the engine’s internal components. It is strategically positioned to reinforce the engine’s structure, preventing any undue stress or movement that could lead to mechanical failure. This part ensures that the engine operates smoothly and efficiently by maintaining the alignment and stability of the engine’s various parts.

Cummins 6B5.9 Engine

Similarly, in the Cummins 6B5.9 engine, the Tube Brace part 3925301 is important for providing the necessary support to the engine’s framework. Given the larger size and power of the 6B5.9 engine, the structural integrity provided by this part is even more important. The Tube Brace helps to distribute the engine’s weight evenly, reducing the risk of wear and tear on other components. This ensures that the engine can handle higher loads and maintain optimal performance over time.

Grouping of Engines

Both the 4B3.9 and 6B5.9 engines benefit from the Tube Brace part 3925301 in similar ways, as it is designed to provide robust structural support across different engine sizes and power outputs. The part’s design allows it to be universally applied to these engines, ensuring that they maintain their structural integrity regardless of the specific engine model. This compatibility highlights the versatility and effectiveness of the Tube Brace in supporting Cummins engines.

Role of Part 3925301 Tube Brace in Engine Systems

The 3925301 Tube Brace is an integral component in the structural integrity and efficient operation of various engine systems. It provides support and stability to several key components, ensuring optimal performance and longevity.

Support for Injector Fuel Supply Tube

In fuel injection systems, the injector fuel supply tube is responsible for delivering fuel from the fuel rail to the injectors. The 3925301 Tube Brace plays a role by securing the fuel supply tube in place. This support minimizes vibrations and potential wear on the tube, which can otherwise lead to fuel delivery issues or leaks. By maintaining the tube’s alignment and stability, the Tube Brace ensures consistent fuel flow and pressure, contributing to efficient combustion and engine performance.

Integration with Plumbing Components

The Tube Brace is also vital in the engine’s plumbing system, which includes various hoses and pipes responsible for fluid transfer. Whether it’s coolant, oil, or other fluids, the Tube Brace helps in securing these plumbing components. This support prevents hoses from shifting or coming loose, which could result in fluid leaks or insufficient lubrication. The stability provided by the Tube Brace ensures that the plumbing system operates within specified parameters, enhancing engine reliability and safety.

Fuel System Stability

Within the fuel system, the Tube Brace contributes to the overall stability of fuel lines and connections. By securing fuel lines and preventing them from moving or vibrating excessively, the Tube Brace helps maintain a consistent fuel supply to the engine. This is particularly important in high-performance engines where fuel delivery precision can significantly impact engine output and efficiency. The Tube Brace ensures that fuel lines remain in optimal condition, reducing the risk of fuel starvation or leaks.

Conclusion

The Cummins 3925301 Tube Brace is a key component in maintaining the structural integrity and operational efficiency of various engine systems. Its role in supporting the injector fuel supply tube, plumbing components, and fuel system elements is important for ensuring smooth and reliable engine performance.

-

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

SAE International. (2013). Composite Materials Handbook Volume 4 Metal Matrix Composites.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.