This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

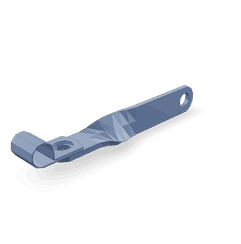

The Cummins 3933303 Tube Brace is a component designed to enhance the structural integrity of commercial trucks. Its purpose is to provide additional support and stability to the truck’s frame, ensuring it can withstand the rigors of heavy-duty operations.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce frames and chassis. They function by distributing loads more evenly across the frame, thereby improving overall stability and durability. In the context of commercial trucks, tube braces play a significant role in maintaining the structural integrity under various operating conditions 1.

Purpose of the 3933303 Tube Brace

The 3933303 Tube Brace is specifically designed to offer additional support to the truck’s frame. It is typically placed in areas where the frame experiences significant stress, such as between frame rails or at points where loads are concentrated. By doing so, it helps in maintaining the alignment and integrity of the frame, which is crucial for the safe operation of the vehicle 2.

Key Features

The 3933303 Tube Brace is constructed from high-strength materials, ensuring it can endure the stresses associated with heavy-duty truck operations. Its design specifications include precise dimensions and robust connections to the frame, which enhance its performance and durability. Additionally, the brace may feature unique attributes such as corrosion-resistant coatings or specialized welding techniques to further improve its longevity 3.

Benefits of Using the 3933303 Tube Brace

Incorporating the 3933303 Tube Brace into a truck’s frame offers several advantages. It improves load distribution, which helps in reducing the stress on individual frame components. This results in enhanced frame rigidity, allowing the truck to maintain its structural integrity over time. Furthermore, the brace increases resistance to wear and stress, contributing to the overall durability of the vehicle 4.

Installation Considerations

When installing the 3933303 Tube Brace, it is important to follow guidelines to ensure optimal performance. Preparatory steps may include cleaning the installation area and inspecting the frame for any existing damage. The use of appropriate tools and ensuring proper alignment are critical to the successful installation of the brace. Careful attention to these details will help in achieving the desired reinforcement effects 5.

Maintenance and Troubleshooting

Regular maintenance checks are recommended to ensure the 3933303 Tube Brace remains in good condition. Common issues may include corrosion or damage from impacts. Troubleshooting tips include inspecting the brace for signs of wear, ensuring all connections are secure, and addressing any corrosion promptly to prevent further degradation 6.

Compatibility and Usage

The 3933303 Tube Brace is designed for use in specific types of trucks and applications. It is important to verify compatibility with the truck model to ensure it fits correctly and functions as intended. Considerations for ensuring compatibility may include checking the frame dimensions and the specific stress points where the brace is needed 7.

Cummins Corporation Overview

Cummins Inc. is a well-established company with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a history of innovation and quality in engine and power generation equipment. The company’s product range includes a variety of components designed to enhance the performance and reliability of commercial vehicles. The 3933303 Tube Brace is part of this extensive lineup, reflecting Cummins’ commitment to quality and durability in their offerings 8.

Role of Part 3933303 Tube Brace in Engine Systems

The 3933303 Tube Brace is an essential component in maintaining the structural integrity and operational efficiency of various engine systems. Its primary function is to provide robust support and stability to the interconnected components within the engine assembly.

Integration with Gauge Systems

In gauge systems, the Tube Brace plays a significant role by securing the gauge housing and ensuring that the gauges remain firmly in place. This stability is vital for accurate readings, as any movement or vibration can lead to erroneous data. The Tube Brace minimizes such risks by absorbing and distributing vibrational forces, thereby enhancing the reliability of the gauge readings 9.

Contribution to Oil Level Monitoring

When it comes to oil level monitoring, the Tube Brace supports the oil level sensor and its associated tubing. By maintaining the correct positioning and alignment of these components, the Tube Brace ensures that the oil level sensor can accurately detect the oil level within the engine. This is particularly important for maintaining optimal lubrication and preventing engine damage due to low oil levels 10.

Enhanced System Performance

Overall, the Tube Brace contributes to the enhanced performance of engine systems by ensuring that all connected components remain securely in place. This not only improves the accuracy of readings but also extends the lifespan of the components by reducing wear and tear caused by excessive movement 11.

Conclusion

The 3933303 Tube Brace by Cummins is a vital component for enhancing the structural integrity and operational efficiency of commercial trucks and engine systems. Its robust design, compatibility across various models, and the benefits it offers in terms of load distribution and durability make it an indispensable part of Cummins’ product lineup. Regular maintenance and proper installation are key to maximizing the effectiveness of this Cummins part.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Engine Testing: Theory and Practice: Third Edition, A.J. Martyr, SAE International, 2007.

↩ -

Generalized Vehicle Dynamics, Daniel Williams, SAE International, 2022.

↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014.

↩ -

General Information, Bulletin Number 3666183, Operation and Maintenance Manual.

↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ -

Engine Testing: Theory and Practice: Third Edition, A.J. Martyr, SAE International, 2007.

↩ -

Generalized Vehicle Dynamics, Daniel Williams, SAE International, 2022.

↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014.

↩ -

General Information, Bulletin Number 3666183, Operation and Maintenance Manual.

↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.