This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tube Brace 3934547, manufactured by Cummins, is a component designed for heavy-duty truck applications. Its purpose is to enhance the structural integrity and performance of trucks by providing additional support and stability. Cummins, a well-established name in the automotive and heavy-duty truck industry, ensures that this tube brace meets the rigorous demands of commercial and industrial use 1.

Basic Concepts of Tube Braces

A tube brace is a structural component used in vehicle frameworks to reinforce and stabilize the chassis. It functions by distributing stress and load more evenly across the vehicle’s structure, which can improve overall durability and performance. In heavy-duty trucks, tube braces play a significant role in maintaining the integrity of the vehicle under various operating conditions 2.

Purpose of the 3934547 Tube Brace

The 3934547 Tube Brace is specifically designed to enhance the structural stability of heavy-duty trucks. It supports other components by providing additional rigidity to the chassis, which can be particularly beneficial in applications where the truck is subjected to heavy loads or rough terrain. This added support helps in maintaining the alignment and integrity of the truck’s frame, contributing to safer and more reliable operation 3.

Key Features

The 3934547 Tube Brace features a robust material composition, typically made from high-strength steel, which ensures durability and resistance to wear and tear. Its design includes precise dimensions and fittings that allow for seamless integration with the truck’s chassis. Unique characteristics may include corrosion-resistant coatings and engineered stress points that enhance its performance in demanding environments 4.

Benefits of Using the 3934547 Tube Brace

Incorporating the 3934547 Tube Brace into truck designs offers several advantages. These include improved durability of the truck’s chassis, enhanced safety through better structural integrity, and potential cost savings over time due to reduced maintenance needs and extended component lifespan. The brace also contributes to more consistent performance under load, which can be critical in commercial applications 5.

Installation Considerations

When installing the 3934547 Tube Brace, it is important to follow guidelines and best practices to ensure proper integration with the truck’s chassis. Preparatory steps may include cleaning the installation area and verifying that all mounting points are free of debris. Required tools typically include wrenches, drills, and possibly a chassis modification kit. Common pitfalls to avoid during installation include improper alignment and over-tightening of fasteners, which can lead to stress concentrations and potential failure points 6.

Troubleshooting and Maintenance

To identify common issues related to the 3934547 Tube Brace, regular inspections should be conducted to check for signs of wear, corrosion, or damage. Diagnostic procedures may involve visual inspections and, in some cases, non-destructive testing methods to assess the integrity of the brace. Maintenance practices to ensure longevity and optimal performance include keeping the brace clean, applying protective coatings as needed, and addressing any signs of damage promptly 7.

Compatibility and Application

The 3934547 Tube Brace is commonly used in various types of heavy-duty trucks, particularly those designed for commercial and industrial applications. Specific models and notable applications may vary, but the brace is engineered to fit within standard chassis configurations, providing versatile use across different truck makes and models 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of components and systems designed to meet the demanding needs of commercial and industrial applications 9.

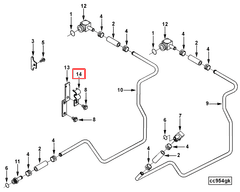

Role of Part 3934547 Tube Brace in Plumbing and Compressor Coolant Systems

Plumbing Systems

In plumbing systems, the 3934547 Tube Brace serves as a vital reinforcement component. It is strategically positioned to support and stabilize the piping network, ensuring that the pipes remain securely in place under various operational pressures and environmental conditions. This reinforcement is particularly important in areas where the plumbing system experiences significant stress, such as near joints, bends, or where the pipes connect to other components. The Tube Brace helps maintain the integrity of the plumbing system, preventing potential leaks and ensuring consistent fluid flow 10.

Compressor Coolant Systems

Within compressor coolant systems, the 3934547 Tube Brace plays an essential role in supporting the coolant lines that circulate through the compressor. These lines are subject to high pressures and temperatures, making structural support imperative to prevent damage or failure. The Tube Brace ensures that the coolant lines remain aligned and secure, which is vital for maintaining efficient heat exchange and preventing coolant leaks. This support is especially important in high-performance compressors where the coolant system operates under extreme conditions. By stabilizing the coolant lines, the Tube Brace contributes to the overall reliability and efficiency of the compressor system 11.

Conclusion

The 3934547 Tube Brace by Cummins is a critical component for enhancing the structural integrity and performance of heavy-duty trucks. Its robust design, precise engineering, and strategic placement make it indispensable in various applications, from truck chassis reinforcement to plumbing and compressor coolant systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring long-term reliability and efficiency in demanding environments.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Cummins Inc. (n.d.). Service Manual (5504189).

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Cummins Inc. (n.d.). Service Manual (5504189).

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.