This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

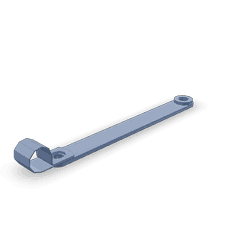

The Cummins 3965085 Tube Brace is a critical component for heavy-duty trucks, enhancing structural integrity and performance. Understanding its functionality is essential for appreciating its role within truck components.

Basic Concepts of Tube Braces

Tube braces are structural elements used to reinforce vehicle frames and chassis, distributing stress and enhancing rigidity. This reinforcement is crucial for maintaining vehicle integrity under various load conditions, contributing to safety and performance 1.

Purpose of the 3965085 Tube Brace

This Cummins part is engineered to support the structural framework of heavy-duty trucks, reinforcing critical chassis areas. It supports other components, contributing to the vehicle’s durability and longevity by providing additional strength to withstand heavy-duty operations.

Key Features

The 3965085 is characterized by its robust material composition and design elements tailored for heavy-duty applications. Constructed from high-strength materials, its design includes precise dimensions and fittings for seamless integration with the truck’s structure, enhancing performance and safety.

Benefits of Using the 3965085 Tube Brace

Incorporating this part into a truck’s design offers advantages such as improved structural stability, enhanced load-bearing capacity, and increased operational efficiency and safety by reducing the risk of structural failure under stress.

Installation Considerations

Proper installation of the 3965085 is crucial for its effectiveness. This involves cleaning the installation area, ensuring all mating surfaces are free of debris, and using appropriate tools and alignment techniques for optimal performance and integration with the truck’s chassis.

Troubleshooting Common Issues

Tube braces, including the 3965085, may encounter issues such as misalignment or damage over time. Early identification through regular inspections can prevent significant structural issues. Solutions may involve realigning the brace, repairing damage, or replacing the component to maintain the truck’s structural integrity.

Maintenance Tips

Routine maintenance of the 3965085 is essential for its longevity and performance. This includes regular inspections for wear or damage, cleaning to remove dirt and debris, and ensuring all connections are secure. Replacement or repair should be considered if significant wear or damage is detected.

Compatibility and Application

The 3965085 is designed for specific models of heavy-duty trucks. Ensuring compatibility with the truck’s existing components is important for optimal performance and safety. Installation considerations should include the truck’s make, model, and any specific design features that may affect how the brace integrates with the chassis.

Cummins: A Brief Overview

Cummins Inc. is a leader in the design and manufacture of diesel engines and related technologies. With a history of innovation and a broad product range, Cummins is renowned for its quality and reliability in the automotive and heavy-duty truck industry. This reputation underscores the trust in components like the 3965085, reflecting Cummins’ commitment to excellence and durability in vehicle components.

Role of the 3965085 Tube Brace in Engine Systems

The 3965085 Tube Brace is integral to maintaining the structural integrity and efficient operation of various engine systems. Its primary function is to provide support and stability to key components, ensuring they operate within specified parameters and tolerances.

Integration with Gauge Systems

In gauge systems, the 3965085 secures the mounting points for pressure and temperature sensors, which are vital for monitoring the engine’s performance and ensuring it operates within safe limits. The brace helps maintain the sensors’ alignment and stability, necessary for accurate readings. Accurate gauge readings are fundamental for timely maintenance and preventing potential engine failures.

Contribution to Oil Level Monitoring

For oil level systems, the 3965085 supports the oil level sensors and associated tubing. Proper support ensures that the sensors remain in the correct position relative to the oil sump, providing reliable oil level readings. This is important for maintaining adequate lubrication, which is essential for reducing friction and wear on moving parts. The brace also helps in managing the routing of oil level indicator tubes, preventing kinks or obstructions that could lead to inaccurate readings or oil flow issues 2.

Conclusion

The 3965085 Tube Brace plays a significant role in enhancing the structural integrity and performance of heavy-duty trucks and engine systems. Its design and functionality contribute to the durability, safety, and efficiency of these vehicles, underscoring the importance of proper installation, maintenance, and understanding of its role within the broader context of truck and engine components.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.