This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

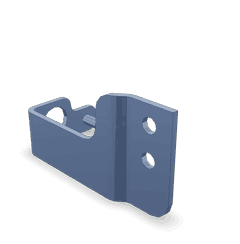

The Tube Support Brace 4000844 is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This brace serves a specific purpose within the structural framework of heavy-duty trucks, contributing to the overall stability and integrity of the vehicle. Cummins, known for its commitment to quality and innovation, produces this part to meet the demanding requirements of heavy-duty applications 1.

Function and Operation

The Tube Support Brace 4000844 operates by providing support and stabilization to various tubes and components within the truck’s structure. It is strategically positioned to reinforce critical areas, ensuring that the tubes remain securely in place under operational stress. This support is vital for maintaining the alignment and functionality of the connected systems, thereby contributing to the truck’s overall performance and safety 2.

Key Features

The primary features of the Tube Support Brace 4000844 include its robust material composition, typically made from high-strength steel, which ensures durability and resistance to wear. The design incorporates precise engineering to maximize strength while minimizing weight. Additionally, the brace may feature unique characteristics such as corrosion-resistant coatings or specialized mounting brackets that enhance its performance in challenging environments 3.

Benefits

The advantages of using the Tube Support Brace 4000844 include improved structural integrity, which is crucial for the longevity and reliability of the truck. Enhanced durability ensures that the brace can withstand the rigors of heavy-duty use, reducing the likelihood of failure. Furthermore, by maintaining proper tube alignment and support, the brace contributes to the overall performance and safety of the vehicle.

Installation Process

Proper installation of the Tube Support Brace 4000844 involves several steps. First, ensure that the truck is securely supported and that all necessary tools are available. The brace should be aligned according to the manufacturer’s specifications, using appropriate fasteners to secure it in place. Attention to detail during installation is important to ensure that the brace functions as intended.

Maintenance and Inspection

Regular maintenance and inspection of the Tube Support Brace 4000844 are recommended to ensure it remains in optimal condition. This includes checking for signs of wear, corrosion, or damage, and addressing any issues promptly. Routine inspections help identify potential problems before they become critical, ensuring the continued reliability of the truck.

Troubleshooting Common Issues

Typical problems that may arise with the Tube Support Brace 4000844 include misalignment, corrosion, or physical damage. Troubleshooting steps involve inspecting the brace for visible signs of wear, ensuring proper alignment, and addressing any corrosion with appropriate treatments. Preventive measures, such as regular inspections and maintenance, can help avoid these issues.

Safety Considerations

When working with the Tube Support Brace 4000844, it is important to follow safety protocols. This includes proper handling of the component, use of personal protective equipment, and adherence to manufacturer guidelines. Ensuring that the work area is safe and that all tools and equipment are in good condition contributes to a secure working environment.

Cummins Overview

Cummins Inc. has a long-standing reputation in the automotive and heavy-duty truck industry. Founded with a commitment to quality and innovation, Cummins offers a wide range of products designed to meet the needs of demanding applications. The company’s focus on research and development ensures that its components, like the Tube Support Brace 4000844, are engineered to deliver reliable performance and durability.

Tube Support Brace (Part 4000844) in Cummins Engines

The Tube Support Brace, identified by part number 4000844, is a critical component in the structural integrity of several Cummins engine models. This part is designed to provide essential support and stability to the engine’s exhaust system, ensuring that the exhaust tubes remain securely in place during operation.

Application in Cummins Engines

QSK45 CM500 and QSK60 CM500

In the QSK45 CM500 and QSK60 CM500 engines, the Tube Support Brace plays a pivotal role in maintaining the alignment and positioning of the exhaust tubes. These engines, known for their robust performance and reliability, benefit from the precise engineering of the Tube Support Brace, which helps to mitigate the stresses and vibrations that can occur during high-output operations. The brace ensures that the exhaust system remains intact, preventing any potential misalignment that could lead to performance issues or damage.

QSK60G

The QSK60G engine also incorporates the Tube Support Brace, part number 4000844, to support its exhaust system. This engine is designed for heavy-duty applications, and the Tube Support Brace is essential in providing the necessary reinforcement to withstand the demanding conditions these engines often face. By securing the exhaust tubes, the brace contributes to the overall durability and longevity of the engine, ensuring that it can operate efficiently and reliably over extended periods.

Importance of the Tube Support Brace

The Tube Support Brace is integral to the structural framework of these engines, ensuring that the exhaust system remains stable and secure. This is particularly important in high-performance and heavy-duty engines, where the exhaust system is subjected to significant stress and vibration. The precise design and placement of the Tube Support Brace help to maintain the integrity of the exhaust system, which is crucial for optimal engine performance and longevity.

Role of Part 4000844 Tube Support Brace in Engine Systems

The 4000844 Tube Support Brace is an integral component in various engine systems, particularly those involving fuel plumbing and injector setups. Its primary function is to provide structural support and stability to the fuel lines and injectors, ensuring that these components remain securely in place during engine operation.

In the context of the Q45 S.O I Fixture Kit and Q60 S.O I Fixture Kit, the Tube Support Brace plays a significant role in maintaining the alignment and integrity of the fuel lines. This is essential for consistent fuel delivery and pressure, which directly impacts engine performance. The brace helps mitigate vibrations and movement that could otherwise lead to fuel line fatigue or disconnection.

For the Q60 SQI 2 Stage Upfit Kit and Q60 SQI Ind Upfit Kit, the Tube Support Brace is equally important. These kits often involve more complex fuel systems with multiple stages or independent injectors. The brace ensures that the additional components are supported adequately, preventing any undue stress on the fuel lines or injectors. This support is vital for the reliable operation of alternative fuel systems, where precision and stability are paramount.

Overall, the 4000844 Tube Support Brace contributes to the durability and efficiency of the engine system by providing necessary support to critical components. Its role in maintaining the structural integrity of fuel plumbing and injector setups cannot be overstated, as it directly influences the performance and reliability of the engine.

Conclusion

The Tube Support Brace 4000844 is a vital component in the structural integrity of heavy-duty trucks and Cummins engines. Its robust design, precise engineering, and strategic placement ensure that critical tubes and components remain securely in place, contributing to the overall performance, safety, and reliability of the vehicle. Regular maintenance and inspection are essential to ensure the continued effectiveness of this part, highlighting its importance in demanding applications.

-

Arthur J Caines, Roger F Haycock and John E Hillier, Automotive Lubricants Reference Book, SAE International, 2004.

↩ -

Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Wiley-ISTE, 2014.

↩ -

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.