This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4001524 Wiring Support Brace is a component designed by Cummins to enhance the electrical system of commercial trucks. This brace plays a role in securing and organizing wiring, which is vital for the reliable operation of the vehicle. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in producing automotive components 1.

Purpose and Function

The 4001524 Wiring Support Brace serves to secure and organize the wiring within a truck’s electrical system. By maintaining the integrity and organization of the wiring, this brace contributes to the overall functionality and safety of the vehicle. It helps prevent wire chafing and damage, which can lead to electrical failures, and ensures that the electrical components operate efficiently 2.

Key Features

The 4001524 Wiring Support Brace is characterized by its robust design and the use of durable materials. It is engineered to withstand the harsh conditions typically encountered in commercial trucking environments. The brace features a sturdy construction that provides reliable support for the wiring, and its design allows for easy integration into the truck’s electrical system. Additionally, the brace may include unique attributes such as corrosion-resistant coatings or adjustable mounting options to enhance its performance and adaptability 3.

Benefits

The installation of the 4001524 Wiring Support Brace offers several benefits. It contributes to improved reliability of the electrical system by securing the wiring and reducing the risk of electrical faults. This can lead to enhanced safety for the vehicle’s operation. Furthermore, by preventing electrical issues, the brace may result in potential cost savings for fleet operators through reduced maintenance and repair needs 4.

Installation and Compatibility

Proper installation of the 4001524 Wiring Support Brace is important to ensure its effectiveness. Guidelines for installation should be followed to integrate the brace seamlessly into the truck’s electrical system. Compatibility with various truck models and electrical systems should be considered to ensure optimal performance and integration 5.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and effectiveness of the 4001524 Wiring Support Brace. This may include periodic inspections for signs of wear or damage and ensuring that the brace remains securely fastened. Common troubleshooting tips can help address potential issues, such as checking for loose connections or signs of corrosion 6.

Safety Considerations

When working with the 4001524 Wiring Support Brace, it is important to observe safety practices and considerations. This includes proper handling during installation and maintenance, adherence to manufacturer guidelines, and ensuring that all electrical connections are secure and correctly installed to prevent hazards 7.

Cummins Overview

Cummins is a reputable manufacturer with a history of producing high-quality automotive components. The company is recognized for its commitment to innovation and excellence in the industry. Cummins’ reputation is built on a foundation of delivering reliable and durable products that meet the demanding requirements of commercial trucking applications 8.

Wiring Support Brace (Part 4001524) in Cummins Engines

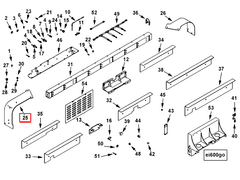

The Wiring Support Brace, identified by the part number 4001524, is a component in the Cummins QSK45 CM500 and QSK60 CM500 engines. This part plays a role in maintaining the integrity and functionality of the engine’s electrical system by providing structural support to the wiring harness.

In the QSK45 CM500 and QSK60 CM500 engines, the Wiring Support Brace is strategically positioned to secure the wiring harness against the engine block. This positioning ensures that the wiring is protected from potential damage due to engine vibrations, thermal expansion, and other operational stresses. The brace is designed to withstand the harsh conditions within the engine compartment, including high temperatures and exposure to various engine fluids.

The design of the Wiring Support Brace in these engines is engineered to facilitate easy installation and maintenance. It is typically made from durable materials that can endure the rigors of the engine environment. The brace’s placement is optimized to minimize interference with other engine components, ensuring that it does not obstruct the engine’s operation or maintenance procedures.

By providing a stable and secure mounting point for the wiring harness, the Wiring Support Brace helps to maintain the reliability and efficiency of the engine’s electrical system. This is important for the overall performance and longevity of the QSK45 CM500 and QSK60 CM500 engines, as it helps to prevent electrical faults and failures that could lead to downtime and increased maintenance costs 9.

Part 4001524 Wiring Support Brace Component Usage

The Part 4001524 Wiring Support Brace is an integral component in the secure and organized routing of various wiring systems within engine compartments. Its primary function is to provide a stable and protective pathway for wiring harnesses, ensuring that electrical connections remain intact and secure under the dynamic conditions of engine operation.

Integration with Accessories

When integrating with accessories, the Wiring Support Brace plays a significant role in maintaining the structural integrity of the accessory wiring. It ensures that wires leading to components such as alternators, fuel pumps, and other auxiliary systems are shielded from potential damage caused by engine vibrations or heat. This support is essential for the reliable operation of these accessories, as it prevents wire fatigue and potential electrical failures 10.

Electrical System Stability

In the electrical system, the brace is positioned to support critical wiring that powers various engine components. It helps in organizing the wiring harness, reducing the risk of short circuits and ensuring that electrical signals are transmitted efficiently. This is particularly important for systems that require precise timing and consistent power delivery, such as ignition systems and engine control units (ECUs) 11.

Mounting and Structural Support

For mounting purposes, the Wiring Support Brace offers a robust framework that can be securely attached to the engine block or other stable structures within the engine bay. This mounting capability is vital for maintaining the position of the wiring harness, especially in high-stress areas where the engine’s movement could otherwise dislodge or damage the wires 12.

Engine Monitor Systems

In conjunction with engine monitor systems, the brace ensures that sensor wires and data cables are properly routed and protected. This is important for maintaining the accuracy and reliability of the data collected by the engine monitor, which is crucial for diagnostics and performance tuning. The brace helps in preventing wire interference and ensures that the monitor systems receive clean, uninterrupted signals 13.

Wiring Harness Organization

Finally, the brace is instrumental in the overall organization of the wiring harness. By providing a dedicated path for the wires, it helps in reducing clutter within the engine compartment. This not only aids in easier maintenance and troubleshooting but also enhances the aesthetic appeal of the engine bay by keeping the wiring neat and orderly 14.

Conclusion

The 4001524 Wiring Support Brace is a vital component in the electrical systems of commercial trucks, particularly in Cummins engines. Its robust design, durability, and strategic placement contribute to the reliability and efficiency of the electrical system. By securing and organizing the wiring, this Cummins part plays a crucial role in preventing electrical faults, enhancing safety, and reducing maintenance costs. Proper installation, regular maintenance, and adherence to safety practices are essential to maximize the benefits of this part.

-

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Khajepour, A. (2023). Synthesis Lectures on Advances in Automotive Technology. Springer.

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩ -

Cummins Inc. (n.d.). Service Manual (5579835).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.