This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4001620 Wiring Brace is a component designed to support and organize the wiring harnesses in commercial trucks. Its role is significant in maintaining the integrity and efficiency of the truck’s electrical system. By securing the wiring harnesses, it helps prevent damage and ensures that electrical connections remain stable under various operating conditions 1.

Purpose of the 4001620 Wiring Brace

The primary function of the 4001620 Wiring Brace is to organize and secure the wiring harnesses within the truck’s electrical system. This organization helps in reducing the risk of wires coming into contact with moving parts or sharp edges, which could lead to damage or electrical faults. Additionally, it plays a role in maintaining the overall tidiness of the engine compartment, which can be particularly beneficial during maintenance checks 2.

Key Features

The 4001620 Wiring Brace is constructed from durable materials that can withstand the harsh conditions often encountered in commercial trucking. It offers various mounting options, allowing it to be securely attached in different configurations depending on the truck’s design. The brace is also designed with considerations for ease of access during maintenance, ensuring that it does not obstruct necessary components or pathways 3.

Benefits

One of the main benefits of the 4001620 Wiring Brace is improved wire management, which contributes to a more organized engine compartment. This organization can lead to reduced risk of electrical faults due to wire damage. Additionally, the brace’s durable construction enhances its ability to withstand harsh operating conditions, providing long-term reliability 4.

Installation Process

Installing the 4001620 Wiring Brace involves several steps to ensure it is properly secured and functions as intended. Begin by identifying the optimal location for the brace within the engine compartment. Next, use the provided mounting hardware to attach the brace securely. It is important to follow the manufacturer’s guidelines for torque specifications to ensure the brace is fastened correctly without over-tightening. After installation, verify that the wiring harnesses are properly routed through the brace and that there is no interference with other components.

Troubleshooting Common Issues

Common issues with the 4001620 Wiring Brace may include loose mounting, which can lead to ineffective wire management, or damage to the brace itself. To address these issues, first, ensure that all mounting hardware is tightened to the specified torque. If the brace is damaged, assess the cause to prevent recurrence and replace the brace if necessary. Regular inspections can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 4001620 Wiring Brace, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring that all mounting hardware remains secure, and verifying that the wiring harnesses are properly routed. Cleaning the brace and surrounding area can also help prevent the accumulation of debris that could interfere with its function.

Compatibility and Applications

The 4001620 Wiring Brace is designed for use in specific types of trucks and engine models. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. Application considerations may include the specific layout of the engine compartment and the routing of the wiring harnesses.

Safety Considerations

When working with the 4001620 Wiring Brace, it is important to observe safety practices to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the truck’s engine is off and cooled down before beginning work, and following all manufacturer guidelines for installation and maintenance. Adhering to these safety practices helps ensure compliance with industry standards and protects both the technician and the equipment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and a strong reputation in the commercial truck industry, Cummins products are known for their reliability, performance, and efficiency. The company’s commitment to quality and customer satisfaction has established it as a trusted name in the industry.

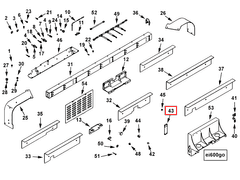

Wiring Brace 4001620 in Cummins Engines

The Wiring Brace 4001620, manufactured by Cummins, is a crucial component in the QSK45 CM500 and QSK60 CM500 engines. This part plays a vital role in securing and organizing the engine’s wiring, ensuring that electrical connections remain stable and reliable under operational conditions.

In the QSK45 CM500 engine, the Wiring Brace 4001620 is strategically positioned to maintain the integrity of the wiring harness. Its design allows it to withstand the vibrations and stresses inherent in engine operation, preventing potential damage to the wiring and ensuring consistent performance.

Similarly, in the QSK60 CM500 engine, the Wiring Brace 4001620 is integral to the engine’s electrical system. It provides a robust framework for the wiring, reducing the risk of disconnections or short circuits that could lead to operational failures.

Both engines benefit from the use of this part, as it enhances the overall reliability and longevity of the engine’s electrical components. The Wiring Brace 4001620 is a testament to Cummins’ commitment to quality and durability, ensuring that these engines operate smoothly and efficiently.

Role of Part 4001620 Wiring Brace in Engine Systems

The 4001620 Wiring Brace is an integral component in the assembly and functionality of various engine systems. It serves as a supportive structure that ensures the secure and organized routing of wiring harnesses throughout the engine compartment.

Integration with Accessories and Electrical Systems

In the context of accessories and electrical systems, the 4001620 Wiring Brace provides a stable framework for the wiring harness. This ensures that electrical connections remain intact and protected from vibrations and physical stress, which is essential for the reliable operation of accessories such as lights, sensors, and other electronic components.

Support for Brace and Harness Assembly

The brace itself is designed to work in conjunction with the harness assembly to maintain the integrity of the wiring system. By securing the harness in place, the Wiring Brace prevents chafing and abrasion, which can lead to electrical faults. This is particularly important in high-vibration environments typical of engine compartments.

Mounting and Engine Monitor Compatibility

When it comes to mounting, the 4001620 Wiring Brace offers a robust solution for attaching wiring harnesses to the engine frame or other structural components. This secure mounting is vital for the engine monitor, ensuring that all sensor data is accurately transmitted without interference from loose or damaged wires.

Enhanced Wiring Harness Protection

The Wiring Brace plays a significant role in protecting the wiring harness from environmental factors such as heat, moisture, and physical impact. By providing a shielded pathway for the wires, it enhances the durability and reliability of the entire electrical system within the engine.

Conclusion

In summary, the 4001620 Wiring Brace is a key component in maintaining the structural and functional integrity of wiring systems in engine compartments, ensuring that all electrical and accessory systems operate smoothly and reliably.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.