This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

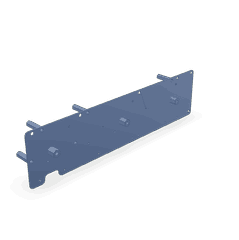

The 4015836 Wiring Brace, manufactured by Cummins, is a component designed to enhance the electrical system’s integrity in commercial trucks. Cummins, a well-established name in the commercial truck industry, offers a range of parts and systems aimed at improving the efficiency, reliability, and safety of truck operations. This Cummins part is part of this commitment, providing a solution for organizing and securing wiring harnesses within the truck’s electrical system.

Purpose of the 4015836 Wiring Brace

This part plays a role in the electrical system of a truck by organizing and securing wiring harnesses. This function is vital for preventing damage to the wiring from vibrations, heat, or physical contact with other components. By securing the wiring, the brace helps maintain reliable electrical connections, which is crucial for the proper operation of the truck’s electrical systems. It also aids in protecting the wiring from environmental factors, such as moisture and debris, that could lead to corrosion or other forms of damage.

Key Features

The design and construction of the 4015836 Wiring Brace incorporate several features that enhance its performance and durability. It is made from materials that offer resistance to corrosion and physical damage, ensuring longevity in demanding commercial truck environments. The brace provides multiple mounting options, allowing for flexible installation that can accommodate various truck models and configurations. Its unique characteristics, such as a robust yet lightweight design, contribute to its effectiveness in securing wiring harnesses without adding unnecessary weight to the vehicle.

Benefits

Incorporating the 4015836 Wiring Brace into a truck’s electrical system offers several advantages. It contributes to improved electrical system reliability by ensuring that wiring harnesses remain securely in place and are protected from potential damage. This reduces the risk of short circuits and other electrical issues that could arise from unsecured or damaged wiring. Furthermore, by maintaining the integrity of the electrical system, the brace enhances overall truck performance and safety, ensuring that all electrical components operate as intended.

Installation

Proper installation of the 4015836 Wiring Brace is key to maximizing its benefits. The process involves securing the brace to the truck’s frame or other designated mounting points and then routing the wiring harnesses through the brace. Tools required may include wrenches, screwdrivers, and possibly a drill for creating mounting holes. It is recommended to follow the manufacturer’s guidelines for installation to ensure the brace is correctly positioned and securely fastened. Attention should be paid to any potential challenges, such as limited access to mounting points or the need to navigate around existing components.

Maintenance and Troubleshooting

To ensure the 4015836 Wiring Brace continues to perform optimally, regular maintenance is recommended. This includes inspecting the brace and wiring harnesses for signs of wear, damage, or loose connections. Cleaning the brace to remove any accumulated dirt or debris can also help maintain its effectiveness. Troubleshooting common issues, such as loose connections or damaged wiring, should be done according to the manufacturer’s recommendations to prevent further damage and ensure safety.

Safety Considerations

When working with the 4015836 Wiring Brace, it is important to follow safety precautions and best practices. This includes ensuring the truck’s electrical system is de-energized before beginning any work to prevent electrical shock. Proper handling of the brace and wiring harnesses is also crucial to avoid injury or damage. Compliance with relevant industry standards and regulations should be maintained throughout the installation, maintenance, and troubleshooting processes to ensure safety and effectiveness.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product offerings are designed to meet the diverse needs of its customers, enhancing the performance, efficiency, and safety of commercial vehicles.1

Cummins Wiring Brace 4015836 Compatibility

The Cummins Wiring Brace part number 4015836 is a critical component designed to secure and organize wiring within various engine systems. This part is engineered to fit seamlessly with the following Cummins engines:

- QSK45 CM500

The QSK45 CM500 engine is known for its robust design and high performance, often utilized in heavy-duty applications such as marine and industrial settings. The Wiring Brace 4015836 ensures that the wiring remains neatly arranged, reducing the risk of damage and enhancing the overall efficiency of the engine’s electrical system.

By integrating the Wiring Brace 4015836 into the engine’s setup, users can expect improved reliability and easier maintenance, as the organized wiring minimizes potential points of failure and simplifies troubleshooting processes.

Role of Part 4015836 Wiring Brace in Engine Systems

The 4015836 Wiring Brace is an essential component that ensures the secure and organized routing of electrical cables within engine systems. Its primary function is to maintain the integrity and efficiency of the electrical connections by providing a stable and protected pathway for the wiring harness.

Integration with Mounting Systems

When integrated with mounting systems, the 4015836 Wiring Brace plays a significant role in securing the wiring harness in place. This prevents undue stress on the cables, which can lead to wear and potential failure. By anchoring the harness, the brace ensures that vibrations and movements typical in engine operations do not compromise the electrical connections.

Interaction with Engine Monitor

The engine monitor relies on consistent and reliable data from various sensors distributed throughout the engine. The 4015836 Wiring Brace facilitates this by ensuring that the wiring harness, which carries signals from these sensors to the monitor, remains intact and free from interference. This stable connection is vital for accurate monitoring and diagnostics, allowing for timely maintenance and preventing potential engine malfunctions.

Support for Wiring Harness

The wiring harness is a complex network of cables that transmit power and data to and from different engine components. The 4015836 Wiring Brace supports this network by providing a structured route for the harness. This organization not only protects the cables from physical damage but also reduces the risk of electrical interference, ensuring that the engine operates smoothly and efficiently.

Conclusion

In summary, the 4015836 Wiring Brace is a key component in maintaining the reliability and performance of engine systems by securing and organizing the wiring harness, supporting mounting systems, and ensuring the engine monitor receives accurate data. Its integration into engine systems enhances overall efficiency, reliability, and safety, making it a valuable addition to any commercial truck’s electrical system.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.