This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

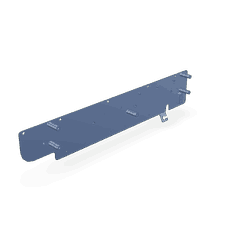

The Cummins 4016327 Wiring Brace is a component designed to enhance the electrical system of heavy-duty trucks. Its purpose is to support and organize the wiring, ensuring that the electrical system operates efficiently and remains protected from potential damage. This component is significant in maintaining the integrity and reliability of the truck’s electrical infrastructure.

Purpose and Function

The 4016327 Wiring Brace plays a role in the electrical system by providing a structured framework for the wiring. It helps in organizing the wires, reducing the risk of tangling and abrasion, which can lead to electrical faults. By securing the wires in place, it ensures that they are less likely to be damaged by vibrations or movement, thereby contributing to the overall efficiency and safety of the truck’s electrical system 1.

Key Features

The primary features of the 4016327 Wiring Brace include its robust design and the materials used in its construction. Typically made from durable materials, it is built to withstand the harsh conditions often encountered in heavy-duty truck environments. Its design allows for easy integration into the truck’s existing electrical system, providing a stable and secure platform for the wiring 2.

Benefits

The advantages provided by the 4016327 Wiring Brace include improved wire management, which leads to a more organized and efficient electrical system. By reducing the risk of electrical faults, it enhances the safety and reliability of the truck. Additionally, the brace contributes to the longevity of the wiring by protecting it from physical damage, thereby reducing the need for frequent repairs or replacements 3.

Installation

Proper installation of the 4016327 Wiring Brace involves several steps. First, the area where the brace will be installed should be cleaned and prepared. The brace should then be positioned according to the manufacturer’s guidelines, ensuring it is aligned correctly with the existing wiring. Tools required may include wrenches and screwdrivers, depending on the specific model. Following the installation, it is important to test the electrical system to ensure everything is functioning correctly.

Maintenance and Troubleshooting

Maintaining the 4016327 Wiring Brace involves regular inspection to ensure it remains in good condition. This includes checking for any signs of wear or damage and ensuring that the wiring is securely held in place. Cleaning the brace periodically can also help in preventing the buildup of dirt or debris that could affect its performance. Common troubleshooting methods involve checking for loose connections or signs of electrical faults, which may indicate the need for repairs or adjustments.

Safety Considerations

When using the 4016327 Wiring Brace, it is important to adhere to safety guidelines. This includes taking precautions during installation and maintenance to avoid electrical shocks or injuries. Following the manufacturer’s instructions and using the appropriate tools and equipment can help ensure a safe working environment. Additionally, regular inspections and maintenance can help identify potential issues before they become serious problems.

Cummins Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of developing reliable and efficient engine and component solutions, Cummins has built a reputation for excellence. The company’s products, including the 4016327 Wiring Brace, are designed with a focus on durability, performance, and safety, reflecting Cummins’ dedication to meeting the needs of its customers in the heavy-duty truck sector.

Integration of Wiring Brace Part 4016327 in Cummins Engines

The Wiring Brace part 4016327, manufactured by Cummins, is a critical component in the electrical systems of the QSK45 CM500 and QSK60 CM500 engines. This part is integral to maintaining the structural integrity and organization of the engine’s wiring harness.

In the QSK45 CM500 engine, the Wiring Brace part 4016327 is strategically positioned to secure and stabilize the wiring harness, ensuring that it remains in place under various operational conditions. This is particularly important in maintaining the reliability and efficiency of the engine’s electrical systems, which are crucial for the engine’s overall performance.

Similarly, in the QSK60 CM500 engine, the Wiring Brace part 4016327 plays a pivotal role in the same capacity. Given the larger size and more complex electrical systems of the QSK60 CM500, the importance of this part is even more pronounced. It helps in preventing the wiring harness from becoming dislodged or damaged, which could lead to electrical faults and potential engine downtime.

Both engines benefit from the use of the Wiring Brace part 4016327, as it contributes to the longevity and reliability of the engine’s electrical infrastructure. This part is designed to withstand the rigors of engine operation, ensuring that the wiring harness remains secure and functional throughout the engine’s lifecycle.

Role of Part 4016327 Wiring Brace in Engine Systems

The 4016327 Wiring Brace is an essential component in ensuring the structural integrity and efficient operation of various engine systems. Its primary function is to provide secure mounting for the wiring harness, which is vital for the proper functioning of the engine monitor and other electronic systems.

Integration with Mounting Systems

The wiring brace is designed to integrate seamlessly with the mounting systems within the engine compartment. By securing the wiring harness in place, it prevents undue stress on the wires, which could otherwise lead to disconnections or damage. This stability is particularly important during engine vibrations or rough operating conditions, ensuring that the electrical connections remain intact and functional.

Support for Engine Monitor

An engine monitor relies on a consistent and reliable flow of data from various sensors distributed throughout the engine system. The 4016327 Wiring Brace plays a significant role in this by ensuring that the wiring harness, which carries these signals, is properly supported and organized. This support helps in maintaining the integrity of the data transmission, allowing the engine monitor to provide accurate readings and diagnostics.

Enhancing Wiring Harness Efficiency

The wiring harness is a complex network of wires that facilitates communication between different components of the engine system. The 4016327 Wiring Brace helps in managing this network by keeping the wires neatly arranged and protected. This not only improves the efficiency of the wiring harness but also makes it easier to access and service individual wires if needed. Additionally, the brace helps in reducing the risk of short circuits by preventing wires from coming into contact with each other or with other metal components within the engine bay.

Conclusion

In summary, the 4016327 Wiring Brace is a key component in the engine system, providing essential support and organization for the wiring harness. Its role in securing the harness ensures the reliable operation of the engine monitor and other electronic systems, contributing to the overall efficiency and safety of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.