This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

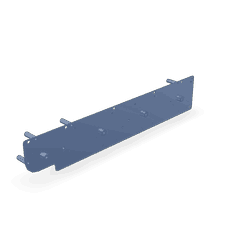

The Cummins 4016333 Wiring Brace is a component designed to enhance the electrical system of commercial trucks. Its primary role is to support and organize the wiring harnesses, ensuring they remain secure and well-arranged. This helps in preventing damage to the wires and maintaining the efficient operation of the truck’s electrical system 1.

Purpose and Function

The Cummins 4016333 Wiring Brace serves a vital function in the truck’s electrical system by supporting and organizing the wiring harnesses. It helps in securing the wires in place, reducing the risk of chafing or abrasion against other components. This organization ensures that the electrical connections remain intact and function efficiently, contributing to the overall reliability of the truck’s electrical system 2.

Key Features

The Cummins 4016333 Wiring Brace is designed with several key features that enhance its performance and durability. It is constructed from high-quality materials that provide robust support for the wiring harnesses. The design of the brace allows for easy installation and ensures that the wires are held firmly in place. Additionally, it features unique attributes such as corrosion-resistant properties and a durable finish, which contribute to its longevity and effectiveness in harsh operating environments 3.

Benefits

The installation of the Cummins 4016333 Wiring Brace offers several benefits. It improves wire management by keeping the harnesses organized and secure, which reduces the likelihood of electrical faults. This organization also enhances the overall reliability of the truck’s electrical system, ensuring that all components function as intended. Furthermore, the brace helps in protecting the wires from physical damage, which can lead to costly repairs and downtime 4.

Installation Process

Installing the Cummins 4016333 Wiring Brace involves several steps to ensure proper fitting and function. Begin by identifying the correct location for the brace within the truck’s electrical system. Use the appropriate tools to secure the brace in place, ensuring that it is firmly attached to the designated mounting points. Route the wiring harnesses through the brace, making sure they are neatly organized and free from tension. Finally, double-check all connections to ensure they are secure and properly aligned.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4016333 Wiring Brace is important to ensure its continued effectiveness. Inspect the brace periodically for signs of wear or damage, and check that the wiring harnesses remain securely in place. If any issues such as wire abrasion or electrical shorts are detected, address them promptly to prevent further complications. Keeping the brace clean and free from debris will also contribute to its longevity and performance.

Compatibility and Usage

The Cummins 4016333 Wiring Brace is designed for use in specific types of trucks and engine models. It is important to verify compatibility with the truck’s make and model to ensure optimal performance. Follow any specific usage notes or recommendations provided by the manufacturer to maximize the effectiveness of the brace within the electrical system.

Safety Considerations

When installing or maintaining the Cummins 4016333 Wiring Brace, it is important to observe safety practices. Ensure that the truck’s electrical system is de-energized before beginning any work to prevent the risk of electrical shock. Use personal protective equipment such as gloves and safety glasses to protect against potential hazards. Adhere to all electrical safety protocols to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and automotive components, with a rich history of innovation and quality. The company is known for its commitment to producing reliable and high-performance parts, including the Cummins 4016333 Wiring Brace. Cummins’ expertise in engine technology and component design ensures that their products meet the demanding requirements of commercial truck applications.

Wiring Brace Part 4016333 in Cummins Engines

The Wiring Brace part number 4016333, manufactured by Cummins, is an essential component in the electrical systems of various Cummins engines. This part is specifically designed to secure and stabilize wiring harnesses, ensuring they remain in place and are protected from potential damage due to engine vibrations and movements.

Application in QSK45 CM500 and QSK60 CM500 Engines

In the QSK45 CM500 and QSK60 CM500 engines, the Wiring Brace part 4016333 plays a crucial role in maintaining the integrity of the electrical system. These engines, known for their robust performance and reliability, require precise and secure wiring to function optimally. The Wiring Brace helps in:

- Preventing Wire Damage: By securing the wiring harnesses, it reduces the risk of wear and tear caused by engine vibrations.

- Maintaining Electrical Connections: It ensures that all electrical connections remain intact and properly aligned, which is vital for the engine’s performance and safety.

- Enhancing Durability: The brace contributes to the longevity of the wiring system by preventing accidental disconnections and physical strain on the wires.

The installation of the Wiring Brace part 4016333 in these engines is a straightforward process, typically involving securing it to designated mounting points using screws or bolts. This ensures that the wiring harnesses are held firmly in place, providing a stable and reliable electrical system.

By integrating the Wiring Brace part 4016333 into the QSK45 CM500 and QSK60 CM500 engines, Cummins ensures that the electrical systems are protected and maintained, contributing to the overall reliability and efficiency of the engines.

Role of Part 4016333 Wiring Brace in Engine Systems

The 4016333 Wiring Brace is an integral component in the assembly and functionality of various engine systems. Its primary role is to provide structural support and organization for the wiring harness, ensuring that the electrical connections remain secure and intact throughout the operation of the engine.

Integration with Mounting Systems

When installed, the 4016333 Wiring Brace interacts closely with the mounting systems of the engine. It secures the wiring harness in place, preventing it from shifting or becoming dislodged during engine vibrations. This stability is essential for maintaining consistent electrical connections, which are vital for the proper functioning of the engine’s electronic components.

Support for Engine Monitor

The Engine Monitor relies on a stable and organized wiring system to accurately collect and transmit data from various sensors throughout the engine. The 4016333 Wiring Brace plays a significant role in this process by keeping the wiring harness neatly arranged and protected. This arrangement ensures that the Engine Monitor receives reliable data, allowing for precise monitoring and diagnostics of the engine’s performance.

Organization of Wiring Harness

The Wiring Harness is a complex network of wires that connect different components of the engine. The 4016333 Wiring Brace helps in organizing this network by bundling and securing the wires. This organization not only protects the wires from physical damage but also reduces the risk of electrical interference. As a result, the engine’s electronic systems can operate more efficiently and reliably.

Conclusion

In summary, the Cummins 4016333 Wiring Brace is a key component in ensuring the structural integrity and organizational efficiency of the wiring systems within engine components. Its role in supporting the mounting systems, enhancing the functionality of the Engine Monitor, and organizing the Wiring Harness contributes significantly to the overall performance and reliability of the engine.

-

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.