This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

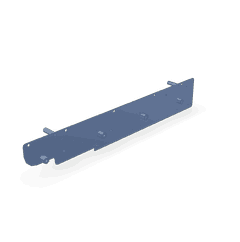

The Cummins 4016338 Wiring Brace is a component designed to enhance the electrical system’s integrity in commercial trucks. Its role is to support and organize the wiring, ensuring that the electrical connections remain secure and undamaged during the vehicle’s operation. This part is significant for maintaining the efficiency and reliability of the truck’s electrical system 1.

Purpose and Function

The Wiring Brace provides a structured framework for the wiring, helping to organize the wires and reduce the likelihood of tangling or abrasion, which can lead to electrical faults. By securing the wires in place, it contributes to the prevention of damage from vibrations and movement, ensuring that the electrical system operates efficiently 2.

Key Features

The Cummins 4016338 Wiring Brace is characterized by its robust design and the materials used in its construction. It is made from durable materials that can withstand the harsh conditions typically encountered in commercial trucking. Its design allows for easy integration into the truck’s electrical system, providing a stable platform for the wiring. Additionally, it features a layout that maximizes space efficiency while ensuring that all wires are adequately supported 3.

Benefits

The installation of the Wiring Brace offers several advantages. It improves wire management by keeping the wires organized and protected. This organization reduces the risk of electrical faults that can arise from damaged or tangled wires. Furthermore, by ensuring the wires remain in optimal condition, the Wiring Brace enhances the safety and reliability of the truck’s electrical system, contributing to overall vehicle performance.

Installation

When installing the Cummins 4016338 Wiring Brace, it is important to follow guidelines and best practices to ensure proper integration into the truck’s electrical system. This may involve using specific tools and additional components to secure the brace in place. Careful attention to the manufacturer’s instructions will help in achieving a secure and effective installation.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and effectiveness of the Wiring Brace. This includes periodic inspections to check for any signs of wear or damage. Common issues that may arise include loose connections or damage to the brace itself. Troubleshooting these problems typically involves tightening connections or replacing damaged components to restore the electrical system’s integrity.

Cummins Overview

Cummins Inc. is a well-established manufacturer of diesel engines and related technologies. With a history of innovation and quality, Cummins has developed a wide range of automotive components, including the Wiring Brace. The company’s commitment to excellence is reflected in the design and performance of its products, which are trusted by professionals in the automotive industry.

Role of Part 4016338 Wiring Brace in Engine Systems

The Part 4016338 Wiring Brace is an integral component in the assembly and functionality of various engine systems. It primarily serves to secure and organize the wiring harness, ensuring that the electrical connections remain intact and are not susceptible to damage from vibrations or movement.

Integration with Mounting Systems

When installed, the Wiring Brace works in conjunction with the mounting system to provide a stable platform for the engine’s electrical components. This stability is essential for maintaining the integrity of the wiring harness, which carries vital signals and power to different parts of the engine. The brace helps to distribute the stress exerted on the wiring, reducing the likelihood of fraying or disconnection.

Interaction with Engine Monitor

The engine monitor relies on a consistent and reliable flow of data from various sensors distributed throughout the engine. The Wiring Brace plays a significant role in this process by keeping the wiring harness neatly arranged and protected. This arrangement ensures that the signals transmitted to the engine monitor are accurate and uninterrupted, allowing for precise monitoring and control of engine performance.

Support for Wiring Harness

The wiring harness is a complex network of cables that transmit power and data to and from the engine’s electronic control unit (ECU) and other components. The Wiring Brace supports this harness by providing a structured pathway, which minimizes the risk of wires becoming tangled or damaged. This support is particularly important in high-vibration environments, where unsecured wiring can lead to intermittent connections or complete failures.

Conclusion

The Cummins 4016338 Wiring Brace enhances the reliability and efficiency of engine systems by securing and organizing the wiring harness, ensuring stable connections with the mounting system, and supporting accurate data transmission to the engine monitor. Its robust design and durable materials make it a critical component for maintaining the integrity of the electrical systems in commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.