This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

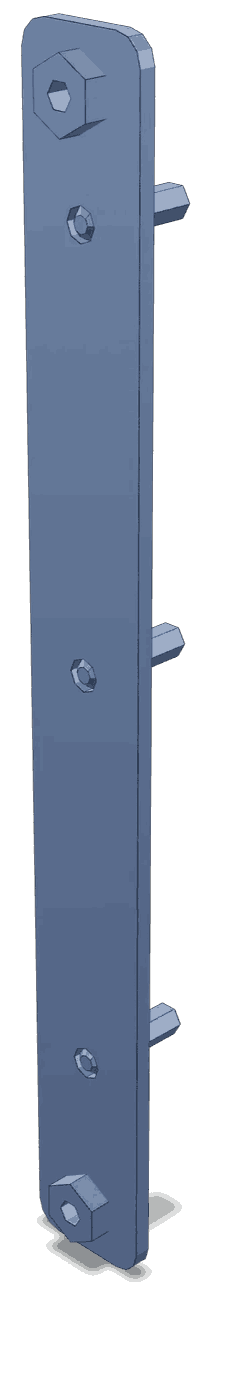

The 4016678 Wiring Brace is a component designed to enhance the electrical system of commercial trucks. Manufactured by Cummins, a reputable company in the automotive industry, this part plays a role in organizing and supporting the wiring within the truck, contributing to the overall efficiency and safety of the vehicle’s electrical operations 1.

Purpose and Function

The Wiring Brace serves to organize and secure the wiring within a truck’s electrical system. By providing a structured framework, it helps maintain the integrity of the wiring, reducing the likelihood of tangling or damage. This organization ensures that electrical signals are transmitted efficiently, which is vital for the proper functioning of various truck systems 2.

Key Features

This Cummins part is constructed from durable materials that offer both strength and flexibility. Its design allows for easy integration with existing wiring systems, ensuring a secure fit. The brace is engineered to withstand the rigors of commercial truck operations, providing long-lasting performance 3.

Benefits of Using a Wiring Brace

Incorporating a wiring brace into a truck’s electrical system offers several advantages. It improves the organization of wires, which can lead to easier maintenance and reduced downtime. Additionally, the brace helps minimize the risk of short circuits by keeping wires separated and secure. This enhanced organization contributes to the overall durability and reliability of the truck’s electrical system.

Installation Process

Installing the 4016678 involves several steps. First, ensure that the truck’s electrical system is powered down to avoid any risk of electrical shock. Next, identify the area where the brace will be installed and prepare the space by removing any existing wiring that may interfere. Using the appropriate tools, secure the brace in place and route the wires through it, ensuring they are neatly organized and free from tension. Finally, double-check all connections to ensure they are secure and the system is functioning correctly.

Maintenance and Troubleshooting

To maintain the 4016678, regular inspections are recommended to ensure that the wiring remains organized and undamaged. If any issues arise, such as frayed wires or loose connections, they should be addressed promptly to prevent further complications. Common troubleshooting steps include checking for secure connections, ensuring wires are not pinched or damaged, and verifying that the brace remains firmly in place.

Safety Considerations

When working with the 4016678, it is important to follow safety practices to protect both the technician and the vehicle. Always ensure that the truck’s electrical system is powered down before beginning any work. Use insulated tools to avoid electrical shock, and wear appropriate personal protective equipment. Additionally, be mindful of the surrounding environment to prevent any accidental damage to the wiring or brace.

Compatibility and Applications

The 4016678 is designed for use in various types of commercial trucks. It is compatible with a range of electrical systems and is commonly used in specific models and series within the industry. Ensuring compatibility is important to achieve the best performance and integration with the truck’s existing systems.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long history of producing high-quality automotive components. The company is known for its expertise in engine and powertrain technologies, as well as its commitment to innovation and quality. Cummins’ products are designed to meet the demanding requirements of commercial vehicle operations, providing reliable performance and durability.

Customer Reviews and Feedback

Customers who have used the 4016678 have reported positive experiences, noting its effectiveness in organizing wiring and enhancing the reliability of their truck’s electrical system. Common praises include its durability, ease of installation, and the overall improvement in system organization. Some users have also provided constructive feedback on areas for improvement, contributing to the continuous enhancement of the product.

Frequently Asked Questions (FAQ)

What is the 4016678 Wiring Brace? The 4016678 is a component designed to organize and secure the wiring within a truck’s electrical system.

How does the Wiring Brace improve the electrical system? It helps maintain the integrity of the wiring, reducing the likelihood of tangling or damage, and ensures efficient transmission of electrical signals.

What materials is the Wiring Brace made from? It is constructed from durable materials that offer both strength and flexibility.

How should the Wiring Brace be maintained? Regular inspections are recommended to ensure that the wiring remains organized and undamaged. Any issues should be addressed promptly.

What safety practices should be followed when installing the Wiring Brace? Ensure the truck’s electrical system is powered down, use insulated tools, wear appropriate personal protective equipment, and be mindful of the surrounding environment.

Cummins Wiring Brace 4016678 in Engine Applications

The Cummins Wiring Brace part number 4016678 is a component in the electrical systems of several Cummins engine models. This part is designed to secure and organize wiring harnesses, ensuring they remain in place and are protected from damage during engine operation.

QSK60 Engines

The QSK60 engine series, known for its high power output and reliability, incorporates the Wiring Brace 4016678 to maintain the integrity of its electrical architecture. In these engines, the wiring brace helps manage the complex wiring layouts, ensuring that all connections are stable and secure. This is particularly important in the demanding environments where QSK60 engines are often deployed.

CM500 Engines

Similarly, the CM500 engine series benefits from the use of the Wiring Brace 4016678. This engine, designed for both industrial and marine applications, relies on this component to keep its wiring organized. The CM500’s robust design and versatility are complemented by the secure wiring management provided by this brace, ensuring consistent performance and longevity.

Grouping of Engines

Both the QSK60 and CM500 engines share the commonality of operating in high-stress environments, where electrical reliability is paramount. The Wiring Brace 4016678 is integral to these engines’ functionality, providing a stable platform for the wiring harnesses that control critical engine operations. By grouping these engines, it is evident that the wiring brace plays a role in maintaining the operational integrity of these power units.

Role of Part 4016678 Wiring Brace in Engine Systems

The 4016678 Wiring Brace is a component in the integration and support of various wiring harnesses within engine systems. It provides structural integrity and organization to the wiring, ensuring that connections remain secure and protected from potential damage.

Integration with the Engine Control Module (ECM)

In systems where the Engine Control Module (ECM) is present, the 4016678 Wiring Brace plays a role. It supports the wiring harnesses that connect the ECM to various sensors and actuators throughout the engine. This support is vital for maintaining the integrity of the signal paths that the ECM relies on for precise engine management. The brace ensures that wires are neatly routed and secured, reducing the risk of chafing or disconnection that could lead to erratic engine behavior or failure to start.

Support for Engine Modules

Beyond the ECM, the 4016678 Wiring Brace is also instrumental in supporting other engine modules. These may include fuel injection systems, ignition modules, and emission control systems. By providing a stable framework for these wiring harnesses, the brace helps in maintaining consistent electrical connections, which is essential for the reliable operation of these modules. This is particularly important in high-vibration environments typical of engine compartments, where unsecured wiring can lead to intermittent connections or complete failures.

Enhancing System Reliability

The presence of the 4016678 Wiring Brace contributes to the overall reliability of the engine system. It helps in organizing the wiring in a manner that prevents it from coming into contact with moving parts or hot surfaces, which could otherwise cause damage. Additionally, by keeping the wiring tidy and secure, the brace aids in simplifying troubleshooting and maintenance procedures, as technicians can more easily trace and access the necessary wires.

Conclusion

The 4016678 Wiring Brace is a key component in ensuring the structural and functional integrity of wiring harnesses within engine systems. Its role in supporting and organizing these harnesses is fundamental to the reliable operation of engine control modules and other critical engine components.

-

Ferrari, Alessandro, and Pietro Pizzo. Injection Technologies: Mixture Formation Strategies. SAE International, 2022.

↩ -

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.