This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4017568 Wiring Brace is a component designed to enhance the electrical system’s integrity in commercial trucks. Its purpose is to support and organize the wiring, ensuring that the electrical connections remain secure and undamaged during operation. This part plays a role in maintaining the efficiency and reliability of the truck’s electrical system 1.

Purpose and Function

The Cummins 4017568 Wiring Brace serves to secure and organize the wiring within a truck’s electrical system. By holding wires in place, it prevents them from moving excessively, which can lead to wear and tear or accidental disconnections. This organization helps in maintaining a tidy and accessible wiring layout, which is important for both routine maintenance and emergency repairs. Additionally, the brace helps to protect the wires from physical damage caused by vibrations or contact with other components, thereby ensuring consistent electrical performance 2.

Key Features

The Cummins 4017568 Wiring Brace is characterized by its robust design and the materials used in its construction. Typically made from durable plastics or metals, the brace is engineered to withstand the harsh conditions found in commercial truck environments. Its design includes features such as mounting points and channels that allow for secure attachment and organized routing of wires. These attributes contribute to the brace’s performance and longevity, making it a reliable component in the truck’s electrical system 3.

Benefits

Installing the Cummins 4017568 Wiring Brace offers several advantages. It improves wire management by keeping the wires neatly organized and secured, which simplifies access during maintenance checks. This organization reduces the risk of electrical faults that can arise from damaged or disconnected wires. Furthermore, by protecting the wiring from physical damage, the brace enhances the safety and reliability of the truck’s electrical system, potentially reducing downtime and repair costs.

Installation

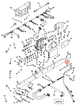

Proper installation of the Cummins 4017568 Wiring Brace involves several steps. First, identify the appropriate location within the truck’s engine compartment where the brace will be mounted. Using the provided mounting hardware, secure the brace in place. Next, route the wires through the designated channels or openings in the brace, ensuring that they are not twisted or kinked. Finally, double-check all connections and the brace’s stability to confirm that it is correctly installed and functioning as intended.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4017568 Wiring Brace involves inspecting it for signs of wear or damage, ensuring that all wires remain securely fastened, and checking for any signs of electrical issues such as frayed wires or loose connections. Common issues that may arise include wires becoming dislodged from the brace or the brace itself showing signs of wear. Troubleshooting these issues typically involves re-securing the wires or, in more severe cases, replacing the brace to maintain the electrical system’s integrity.

Manufacturer Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of diesel engines and related components. With a history spanning over a century, Cummins has built a reputation for producing reliable and high-performance parts. Their product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial trucking. Cummins’ commitment to quality and innovation ensures that their components, like the 4017568 Wiring Brace, are trusted by professionals in the industry.

Wiring Brace 4017568 in Cummins Engines

The Wiring Brace part number 4017568 is a component in the electrical systems of various Cummins engines, including the QSK60 and CM500 series. This part plays a role in securing and organizing the wiring harnesses within the engine compartment, ensuring that electrical connections remain stable and protected from potential damage.

QSK60 Series

In the QSK60 series, the Wiring Brace 4017568 is strategically positioned to manage the complex network of wires that run through the engine bay. This series of engines is known for its robust design and high power output, making the proper management of electrical connections essential for maintaining performance and reliability. The brace helps to prevent wires from tangling or coming into contact with moving parts, which could lead to short circuits or other electrical issues.

CM500 Series

Similarly, in the CM500 series, the Wiring Brace 4017568 is integral to the engine’s electrical infrastructure. The CM500 engines are designed for heavy-duty applications, often found in marine and industrial settings. The Wiring Brace ensures that the wiring remains neatly organized and secured, which is crucial in environments where the engine may be subjected to vibrations and harsh conditions. This organization helps in maintaining the integrity of the electrical system, contributing to the overall longevity and efficiency of the engine.

Grouping of Engines

Both the QSK60 and CM500 series engines benefit from the use of the Wiring Brace 4017568 due to their shared need for reliable and organized electrical systems. The grouping of these engines highlights the versatility and importance of this component in ensuring that the electrical systems operate smoothly and efficiently. The brace’s role in securing wiring harnesses is important in preventing potential failures that could arise from loose or damaged wiring.

Role of Part 4017568 Wiring Brace in Engine Systems

The Part 4017568 Wiring Brace is a component in maintaining the integrity and functionality of various engine systems. It provides structural support and organization for wiring harnesses, ensuring that the electrical connections remain secure and undamaged during engine operation.

Integration with the Engine Control Module (ECM)

In systems incorporating an Engine Control Module (ECM), the Wiring Brace plays a role. The ECM relies on a network of sensors and actuators to monitor and control engine performance. The Wiring Brace secures the wiring harnesses that connect the ECM to these components, preventing wire fatigue and potential short circuits. This ensures consistent data transmission and reliable engine management.

Support for Engine Systems

Beyond the ECM, the Wiring Brace is instrumental in supporting other engine systems. It organizes and protects wires associated with fuel injectors, ignition coils, and various sensors (such as the Mass Air Flow sensor and Oxygen sensor). By keeping these wires neatly bundled and away from moving parts and high-temperature areas, the Wiring Brace helps maintain the efficiency and longevity of the engine systems.

Enhancing System Reliability

The presence of the Wiring Brace contributes to the overall reliability of engine systems. It reduces the risk of wire chafing and abrasion, which can lead to intermittent electrical issues. Additionally, by maintaining the proper spacing between wires, it minimizes the potential for cross-talk, ensuring that signals are accurately transmitted between components.

Conclusion

The Cummins 4017568 Wiring Brace is a fundamental component in the maintenance and operation of engine systems, providing essential support and organization for critical wiring harnesses. Its robust design and strategic placement within the engine compartment ensure that electrical connections remain secure and protected, contributing to the overall efficiency and reliability of the engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.