This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4017634 Wiring Brace is a component designed to enhance the electrical system of heavy-duty trucks. Its purpose is to organize and secure wiring harnesses, ensuring they remain in place and protected from potential damage. This part plays a role in maintaining the integrity and efficiency of the truck’s electrical system 1.

Purpose and Function

The Wiring Brace serves to organize and secure the wiring harnesses within the truck’s electrical system. By keeping the wires neatly arranged and firmly in place, it helps prevent tangling, abrasion, and potential damage from vibrations or movement. This organization ensures that the electrical connections remain reliable and that the system operates efficiently 2.

Key Features

The Cummins 4017634 Wiring Brace is constructed from durable materials designed to withstand the harsh conditions of heavy-duty truck environments. Its design includes features such as mounting points and secure clamps that hold the wiring harnesses in place. These attributes contribute to the brace’s performance and longevity, ensuring it can endure the rigors of daily use 3.

Benefits

The use of the Wiring Brace offers several advantages. It improves wire management by keeping the harnesses organized and protected. This organization reduces the risk of electrical faults that can arise from damaged or tangled wires. Additionally, the brace enhances the overall reliability of the electrical system, contributing to the truck’s performance and safety 4.

Installation Process

Installing the Cummins 4017634 Wiring Brace involves several steps to ensure it is properly secured and functions as intended. Begin by identifying the correct location for the brace within the truck’s electrical system. Use the provided mounting points to attach the brace securely. Ensure that the wiring harnesses are properly routed through the brace and clamped in place. Double-check all connections and clamps to confirm they are tight and secure.

Maintenance and Troubleshooting

To maintain the Wiring Brace, regularly inspect it for signs of wear or damage. Ensure that the clamps remain tight and that the wiring harnesses are not showing signs of abrasion or wear. If any issues are identified, address them promptly to prevent further damage. Common troubleshooting steps include tightening loose clamps, re-routing wires to avoid abrasion points, and replacing any damaged components.

Compatibility and Applications

The Cummins 4017634 Wiring Brace is designed for use in specific types of trucks and engine models. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. Application notes may include specific installation instructions or considerations based on the truck’s electrical system configuration.

Safety Considerations

When working with the Wiring Brace, observe standard electrical safety practices. Ensure the truck’s electrical system is de-energized before beginning any installation or maintenance work. Use appropriate personal protective equipment (PPE) to protect against electrical shocks and other hazards. Follow all manufacturer guidelines and safety protocols to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has a long history of innovation and excellence in engine technology. The company’s product portfolio includes a wide range of engines, components, and technologies designed to meet the demanding needs of heavy-duty applications. Cummins is known for its commitment to quality, reliability, and customer satisfaction.

Application in Cummins Engines

QSK60 Engines

The QSK60 series engines, known for their robust performance and reliability, benefit significantly from the use of the Wiring Brace 4017634. This part ensures that the wiring harnesses remain firmly in place, reducing the risk of electrical faults and enhancing the overall operational safety of the engine.

CM500 Engines

Similarly, the CM500 engines, which are designed for heavy-duty applications, also utilize the Wiring Brace 4017634. In these engines, the wiring brace plays a vital role in maintaining the structural integrity of the wiring system, especially under the demanding conditions of continuous operation and high stress.

Importance of the Wiring Brace

The Wiring Brace 4017634 is essential for several reasons:

- Prevents Wire Damage: By securing the wiring harnesses, it prevents wear and tear that can occur due to engine vibrations.

- Enhances Safety: Ensures that electrical connections remain stable, reducing the risk of short circuits or other electrical failures.

- Improves Reliability: Helps maintain consistent performance by preventing intermittent electrical issues that can arise from loose wiring.

Installation and Maintenance

Proper installation of the Wiring Brace 4017634 is critical to ensure its effectiveness. Technicians should follow the manufacturer’s guidelines for securing the brace in the appropriate locations within the engine compartment. Regular inspections should be conducted to verify that the wiring remains secure and that the brace itself is not showing signs of wear or damage.

Integration with Accessories

In the context of accessories, the Wiring Brace ensures that the wiring for components such as the alternator, starter motor, and fuel injectors remains secure and well-organized. This organization is vital for maintaining the integrity of the electrical connections, which in turn ensures the reliable operation of these accessories. The brace prevents wires from chafing against moving parts or sharp edges, thereby reducing the risk of electrical faults.

Electrical System Stability

Within the electrical system, the Wiring Brace plays a significant role in maintaining the stability of the wiring network. It helps in routing wires away from high-temperature areas and potential sources of electromagnetic interference (EMI). This is particularly important for sensitive electronic components such as the engine control unit (ECU) and sensors. By keeping the wiring organized and protected, the brace contributes to the overall reliability and performance of the electrical system.

Enhanced Maintenance and Diagnostics

The presence of the Wiring Brace simplifies maintenance and diagnostic procedures. By keeping the wiring neatly arranged, it allows mechanics to quickly identify and access specific wires or connectors. This can significantly reduce the time required for troubleshooting electrical issues, leading to more efficient repairs and maintenance.

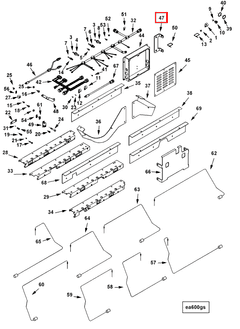

Support for Complex Wiring Configurations

In engines with complex wiring configurations, such as those found in modern vehicles with numerous electronic control systems, the Wiring Brace is indispensable. It supports multiple wiring harnesses, ensuring that they are correctly positioned and secured. This is particularly important in engines where space is at a premium, as it helps in maximizing the use of available space while maintaining the safety and functionality of the electrical system.

Conclusion

The Cummins 4017634 Wiring Brace is a fundamental component that enhances the organization, protection, and reliability of the wiring within engine systems. It directly contributes to the efficient operation of both accessories and the overall electrical system by preventing wire damage, enhancing safety, and improving reliability. Proper installation and regular maintenance of this part are essential to ensure its effectiveness and the continued performance of the engine’s electrical system.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.