This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

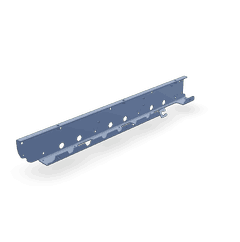

The Cummins 4066148 Wiring Brace is a component designed to enhance the electrical system of commercial trucks. Its primary role is to support and organize the wiring harnesses within the vehicle, ensuring that the electrical system operates efficiently and remains protected from potential damage 1.

Purpose and Function

The Wiring Brace serves a pivotal role in a truck’s electrical system by providing a structured framework for the wiring harnesses. This organization helps in preventing the wires from coming into contact with moving parts or sharp edges, which could otherwise lead to wear and tear or electrical faults. By securing the wires in place, the brace contributes to the stability and reliability of the electrical connections throughout the vehicle 2.

Key Features

This Cummins part is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the harsh conditions typically encountered in commercial trucking environments. The brace is made from durable materials that offer resistance to corrosion and physical impact, ensuring longevity and consistent performance. Its design allows for easy integration with existing wiring systems, facilitating straightforward installation and maintenance 3.

Benefits

Incorporating the Wiring Brace into a truck’s electrical system offers several advantages. It significantly improves wire management by keeping the harnesses organized and protected. This organization reduces the likelihood of electrical faults that can arise from damaged or frayed wires. Additionally, the brace enhances the overall reliability of the truck’s electrical system, contributing to safer and more efficient vehicle operation 4.

Installation

When installing the 4066148, it is important to follow specific guidelines to ensure proper integration with the truck’s electrical system. Preparatory steps include identifying the correct location for the brace and ensuring that all wiring harnesses are clean and free from damage. The installation process may require basic tools such as wrenches and screwdrivers. It is advisable to consult the vehicle’s manual for specific instructions and to avoid common pitfalls such as over-tightening fasteners or improper alignment of the brace 5.

Maintenance and Troubleshooting

Regular maintenance of the Wiring Brace is crucial for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, and cleaning the brace to remove any debris that may accumulate. Common issues that may arise include loose connections or corrosion, which can be addressed by tightening fasteners or applying a corrosion-resistant coating. Prompt attention to these issues can prevent more significant problems down the line 6.

Compatibility and Applications

The 4066148 is designed for use in various commercial truck models and engine types. Its versatility makes it suitable for a wide range of applications within the trucking industry, providing a reliable solution for enhancing electrical system performance across different vehicle configurations 7.

Safety Considerations

When working with the Wiring Brace, it is important to adhere to electrical safety practices. This includes ensuring that the vehicle’s battery is disconnected before beginning any work on the electrical system to prevent the risk of electrical shock. Additionally, wearing appropriate personal protective equipment (PPE) such as gloves and safety glasses is recommended to protect against potential hazards during installation and maintenance 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the industry, known for its commitment to innovation and quality. The company’s product lineup includes a variety of automotive components, such as the Wiring Brace, which are designed to meet the demanding requirements of commercial trucking applications 9.

Application in Cummins Engines

QSK60 CM500

The QSK60 CM500 engine is a high-performance, heavy-duty diesel engine known for its robust construction and reliability. The Wiring Brace 4066148 is specifically engineered to fit within the complex wiring architecture of the QSK60 CM500, providing a secure mounting point for wiring harnesses. This ensures that the electrical connections remain stable and intact, even under the most demanding operating conditions 10.

Other Cummins Engines

While the QSK60 CM500 is a notable example, the Wiring Brace 4066148 is also compatible with a range of other Cummins engines. This part is designed to be versatile, fitting seamlessly into various engine configurations and ensuring that wiring harnesses are properly secured across different models. Its application extends to other Cummins engines, providing a reliable solution for maintaining the integrity of the electrical system in these engines as well 11.

Role of Part 4066148 Wiring Brace in Engine Systems

The 4066148 Wiring Brace is an essential component in the integration and protection of various engine systems. It plays a significant role in ensuring the reliable operation of accessories, electrical components, and the wiring harness 12.

Integration with Accessories

In engine systems, accessories such as alternators, power steering pumps, and air conditioning compressors rely on a stable electrical supply. The 4066148 Wiring Brace helps secure the wiring that powers these accessories, reducing the risk of wire fatigue or damage due to engine vibrations. This ensures consistent performance and longevity of the accessories 13.

Electrical Component Support

Electrical components within the engine compartment, including sensors, control modules, and ignition systems, depend on a robust and secure wiring setup. The 4066148 Wiring Brace provides the necessary support to maintain the integrity of these connections. By keeping wires organized and protected, it helps prevent issues such as short circuits or intermittent connections, which can lead to engine malfunctions 14.

Wiring Harness Protection

The wiring harness is a complex network of wires that transmit power and data throughout the engine system. The 4066148 Wiring Brace plays a key role in safeguarding this harness from physical damage and environmental factors. It ensures that the harness remains in optimal condition, facilitating efficient communication between various engine components and the vehicle’s computer system 15.

Conclusion

Overall, the 4066148 Wiring Brace contributes to the seamless operation of engine systems by providing essential support and protection to critical wiring and electrical components. Its robust design, compatibility with various engine types, and ease of installation make it a valuable component in the maintenance and enhancement of commercial truck electrical systems.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4367224, ISL9 CM2350 L111.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.