This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

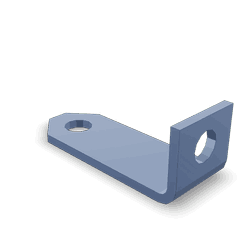

The 4071258 Tube Brace is a component manufactured by Cummins, designed specifically for heavy-duty truck operations. This part is integral to maintaining the structural integrity and performance of trucks under demanding conditions. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in producing reliable automotive components 3.

Basic Concepts of Tube Braces

A tube brace is a structural component used in vehicle frameworks to enhance rigidity and distribute loads more effectively. By reinforcing the chassis or frame, tube braces contribute to the overall stability and durability of a vehicle. In heavy-duty trucks, these braces play a significant role in ensuring that the truck can withstand the stresses of heavy loads and rough terrains, thereby improving both safety and performance 4.

Purpose of Tube Brace 4071258

The Tube Brace 4071258 is designed to reinforce specific areas within a truck’s frame or engine compartment. Its placement is strategic, targeting zones that experience high stress or are prone to flexing under load. By providing additional support in these critical areas, the Tube Brace 4071258 helps maintain the structural integrity of the truck, ensuring that it performs reliably even under extreme conditions 1.

Key Features

The Tube Brace 4071258 is constructed from high-strength materials, ensuring durability and longevity. Its design specifications include precise dimensions and a robust build to integrate seamlessly with the truck’s existing framework. Unique attributes of this tube brace may include corrosion-resistant coatings and a design that allows for easy installation without the need for significant modifications to the truck’s structure 2.

Benefits of Using Tube Brace 4071258

Incorporating the Tube Brace 4071258 into a truck’s design offers several advantages. It enhances the structural integrity of the vehicle, providing added safety for the driver and cargo. Additionally, by reducing flexing and stress on the frame, this brace can contribute to improved operational efficiency and extend the longevity of the truck. The enhanced stability it provides can also lead to better handling and performance on varied terrains 4.

Installation Considerations

Proper installation of the Tube Brace 4071258 is vital to ensure it functions as intended. This process may require specific tools and should be carried out by individuals with the necessary expertise. Key considerations include ensuring the brace is correctly aligned with the truck’s frame, using the appropriate fasteners, and verifying that all connections are secure. Following manufacturer guidelines during installation will help maintain the brace’s effectiveness and durability 3.

Troubleshooting and Maintenance

Common issues with the Tube Brace 4071258 may include corrosion, loosening of fasteners, or physical damage from impacts. Regular inspections can help identify these problems early, allowing for timely repairs or replacements. Maintenance practices should include cleaning the brace to prevent corrosion, checking fasteners for tightness, and assessing the overall condition of the brace for any signs of wear or damage 1.

Cummins: Manufacturer Overview

Cummins has a long-standing reputation in the automotive industry for producing high-quality components. Founded with a commitment to innovation and excellence, Cummins has consistently delivered reliable and durable products. Their focus on research and development ensures that their components, like the Tube Brace 4071258, meet the demanding requirements of heavy-duty applications, providing customers with parts that enhance the performance and reliability of their vehicles 3.

Tube Brace 4071258 Compatibility with Cummins Engines

The Tube Brace part number 4071258, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral in maintaining the structural integrity of the engine by providing support and stability to the engine’s tubes. Below is a detailed breakdown of the engines with which this tube brace is compatible:

QSK Series Engines

- QSK19 CM850 MCRS

- QSK38 CM2150 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

- QSK60 CM850 MCRS

The Tube Brace 4071258 is compatible with the QSK series engines, specifically those with the CM850 and CM2150 configurations. These engines are known for their robust performance and reliability, often used in various industrial and marine applications. The tube brace ensures that the engine’s tubes remain securely in place, preventing any unwanted movement that could lead to mechanical failure.

QSM Series Engine

- QSM11 CM570

The Tube Brace 4071258 also fits the QSM11 CM570 engine. This engine is part of the QSM series, which is designed for high-performance applications. The tube brace in this context is crucial for maintaining the alignment and stability of the engine’s components, ensuring optimal performance and longevity.

By ensuring that the Tube Brace 4071258 is correctly installed, engine operators can maintain the structural integrity of their engines, leading to improved performance and reduced risk of mechanical issues.

Role of Part 4071258 Tube Brace in Engine Systems

The part 4071258 Tube Brace is integral to the structural integrity and efficient operation of various engine systems. It provides essential support and stability to several components, ensuring they function optimally under the demanding conditions of engine operation.

Support for the Crankcase Breather System

The Tube Brace plays a significant role in the arrangement and support of the crankcase breather system. By securing the breather components, it helps maintain the system’s efficiency in venting gases and contaminants from the crankcase, which is vital for engine health 1.

Integration with Oil Level and Gauge Systems

In the oil level and gauge systems, the Tube Brace ensures that the gauge components remain securely in place. This stability is essential for accurate oil level readings, which are necessary for proper engine lubrication and performance 2.

Securing the Harness and Wiring

For the electronic control module wiring and harness, the Tube Brace provides the necessary support to keep these delicate components organized and protected. This is particularly important in preventing wire chafing and ensuring reliable electrical connections 4.

Stability for the Engine Control Module

The Tube Brace also contributes to the stability of the engine control module. By securing this module, it ensures that the engine’s electronic brain remains firmly in place, allowing for precise control over engine functions 3.

Support in Plumbing and Air Fuel Control Systems

In the plumbing and air fuel control systems, the Tube Brace helps maintain the correct alignment and support of various plumbing components. This is essential for the efficient flow of fluids and gases, which directly impacts engine performance 1.

Turbocharger Oil System Support

For engines equipped with a turbocharger, the Tube Brace supports the turbocharger oil system. This includes securing oil lines and components, ensuring that the turbocharger receives the necessary lubrication for optimal performance and longevity 2.

Enhancing Engine Monitoring Systems

In engine monitoring systems, the Tube Brace aids in the secure placement of sensors and monitoring components. This ensures that these systems can accurately track engine parameters, providing valuable data for maintenance and performance tuning 3.

Role in Oil Replenishing Systems

Finally, in oil replenishing systems, the Tube Brace supports the components responsible for maintaining the correct oil levels. This is crucial for ensuring that the engine remains well-lubricated, reducing wear and enhancing efficiency 4.

Conclusion

The 4071258 Tube Brace by Cummins is a critical component for maintaining the structural integrity and performance of heavy-duty trucks. Its strategic placement, robust construction, and compatibility with various Cummins engines make it an essential part for ensuring reliable operation under demanding conditions. Proper installation and maintenance of this part are vital for maximizing its benefits and ensuring the longevity and safety of the vehicle.

-

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ ↩ ↩ ↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ ↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ ↩ ↩ ↩ ↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.