This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

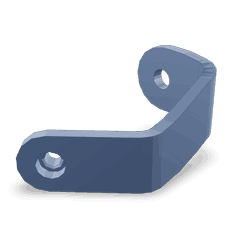

The 4308101 Tube Brace, a component manufactured by Cummins, is designed for use in commercial trucks to enhance structural integrity and performance. This part is integral to the framework of heavy-duty vehicles, providing additional support and stability 1.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle frameworks to reinforce and stabilize the chassis. They distribute stress and load more evenly across the vehicle’s frame, maintaining overall integrity and performance 2.

Purpose of the 4308101 Tube Brace

This Cummins part is designed to enhance the structural integrity of a truck by providing additional support to the chassis. It distributes loads more evenly, preventing frame twisting and bending under heavy loads. This brace reinforces the frame, contributing to the vehicle’s durability and safety 3.

Key Features

The 4308101 Tube Brace is constructed from high-strength materials, ensuring it can withstand heavy-duty use. Its design includes precise dimensions and fittings for secure integration with the truck’s chassis. Unique characteristics may include corrosion-resistant coatings or specific mounting points that enhance functionality and durability in various operating conditions.

Benefits

Utilizing the 4308101 Tube Brace offers several advantages. It improves structural rigidity, enhancing safety by maintaining the truck’s frame integrity under load. Additionally, the brace may contribute to an increase in the truck’s load-carrying capacity by reinforcing the chassis. These benefits translate to better overall performance and longevity of the truck.

Installation Considerations

When installing the 4308101 Tube Brace, it is important to follow guidelines and best practices to ensure optimal performance and integration with the truck’s existing structure. Preparatory steps may include cleaning the installation area and ensuring the chassis is free from any damage that could affect the brace’s effectiveness. Tools required for installation might include wrenches, torque wrenches, and possibly a chassis alignment tool to ensure proper fitting. Alignment considerations are crucial to maintain the truck’s structural integrity and performance.

Troubleshooting and Maintenance

Common issues with tube braces can include corrosion, misalignment, or physical damage from impacts. Regular inspection routines should be established to check for these issues, with cleaning and minor adjustments performed as needed to maintain the brace’s condition. In cases where significant damage is observed, or if the brace shows signs of wear beyond normal use, consideration should be given to replacement to ensure the continued safety and performance of the truck.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial vehicle industry. The company’s extensive product range includes components like the 4308101 Tube Brace, which are designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation and customer satisfaction makes it a trusted source for automotive components in the commercial vehicle sector.

Role of Part 4308101 Tube Brace in Engine Systems

The 4308101 Tube Brace is an essential component in the structural integrity of engine systems, particularly when integrated with specific components such as the location sensor and oil level gauge.

Integration with Location Sensor

When the 4308101 Tube Brace is utilized in conjunction with a location sensor, it provides a stable and secure mounting point. This ensures that the sensor remains firmly in place, even under the dynamic conditions experienced within an engine compartment. The brace helps to mitigate vibrations that could otherwise affect the sensor’s accuracy, thereby enhancing the reliability of positional data collected.

Support for Oil Level Gauge

In systems equipped with an oil level gauge, the 4308101 Tube Brace plays a significant role in maintaining the gauge’s structural stability. By providing a robust attachment point, the brace ensures that the gauge remains securely positioned. This is vital for accurate oil level readings, as any movement or instability could lead to erroneous data. Consistent and reliable oil level measurements are essential for maintaining proper lubrication and preventing engine damage due to low oil levels.

Conclusion

Overall, the 4308101 Tube Brace contributes to the durability and accuracy of engine components by offering a solid foundation for critical sensors and gauges. Its role in enhancing structural integrity and performance makes it a valuable component in commercial fleet operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.