This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

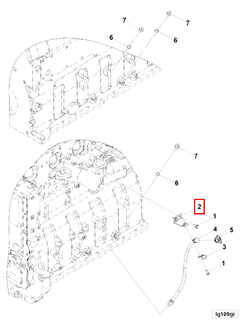

The 4331259 Tube Brace by Cummins is a component designed to enhance the structural integrity of commercial trucks. Its purpose is to provide additional support to the truck frame, ensuring stability and durability under various operating conditions.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce frames and chassis. They contribute to the overall stability and durability of the truck by distributing loads more evenly and preventing frame flex. These braces are typically made from high-strength materials to withstand significant stress and impact 1.

Purpose of the 4331259 Tube Brace

This Cummins part plays a specific role in the operation and structural support of a truck. It enhances the rigidity and load-bearing capacity of the truck frame by providing additional reinforcement. This brace is positioned to counteract stress points and improve the frame’s resistance to deformation under heavy loads or rough terrain 2.

Key Features

The 4331259 is constructed from high-strength steel, ensuring durability and reliability. Its design specifications include precise dimensions and a robust build to integrate seamlessly with the truck frame. Unique attributes of this brace include its engineered shape, which allows for optimal load distribution and minimal weight addition 3.

Benefits

Using this Cummins part offers several benefits, including improved structural integrity and enhanced durability of the truck frame. It can potentially increase the payload capacity by providing additional support where needed. Performance advantages include better handling and reduced risk of frame damage under heavy loads.

Installation Process

Proper installation of the 4331259 involves several steps. First, ensure the truck frame is clean and free of debris. Use the appropriate tools to attach the brace, following the manufacturer’s guidelines for alignment and secure fitting. It is important to check for proper placement and ensure all fasteners are tightened to the specified torque settings.

Troubleshooting and Maintenance

Common issues with the 4331259 may include loose fasteners or minor damage from impacts. Regular inspections should be conducted to check for any signs of wear or damage. Maintenance tips include tightening any loose fasteners and ensuring the brace remains securely attached to the frame. Periodic checks will help ensure longevity and optimal performance.

Safety Considerations

When installing or maintaining the 4331259, it is important to follow safety guidelines. Ensure the truck is stable and use appropriate personal protective equipment. The brace should be used within its designed parameters to avoid any structural compromise. Always refer to the manufacturer’s instructions for safe installation and maintenance practices.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has built a reputation for reliability and performance. The company’s focus on advancing technology and improving efficiency is evident in its wide array of automotive components.

Role of Part 4331259 Tube Brace in Engine Systems

The 4331259 Tube Brace is instrumental in maintaining the structural integrity and optimal performance of various engine components. It provides essential support to the gauge and oil level systems, ensuring their accurate and reliable operation.

Gauge Support

In engine systems, gauges are vital for monitoring various parameters such as temperature, pressure, and fuel levels. The Tube Brace secures the gauge housing, preventing vibrations and mechanical stresses that could lead to inaccurate readings or gauge failure. This support ensures that the gauge remains stable and provides consistent, reliable data to the operator, facilitating informed decision-making during engine operation.

Oil Level System Stability

The oil level system is another area where the Tube Brace plays a significant role. By stabilizing the oil level sensor and its associated components, the Tube Brace helps maintain the sensor’s alignment and functionality. This ensures that the oil level readings are precise, allowing for timely oil changes and maintenance, which are essential for engine longevity and performance.

Conclusion

In summary, the 4331259 Tube Brace is a key component in enhancing the durability and accuracy of gauge and oil level systems within engine environments. Its robust design and precise engineering contribute to the overall stability and performance of commercial trucks, ensuring they operate efficiently and reliably under various conditions.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.