This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

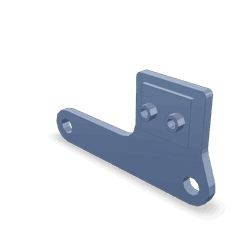

The Tube Brace 4385411, manufactured by Cummins, is a component designed for commercial truck applications. Cummins, a well-established name in the automotive industry, produces a range of parts and systems aimed at enhancing the performance and reliability of commercial vehicles. This Cummins part is significant in this context, offering structural support and contributing to the overall integrity of trucks.

Purpose and Function

This part plays a role in maintaining the structural integrity of a truck. It supports various components within the vehicle, contributing to its stability and durability. By reinforcing the truck’s frame, the Tube Brace helps distribute loads more effectively, reducing stress on other parts and enhancing the vehicle’s longevity 1.

Design and Construction

The Tube Brace 4385411 is constructed using high-strength materials, ensuring durability and resistance to wear and tear. Its design incorporates features that maximize effectiveness and longevity, such as precise dimensions and robust connections. Cummins employs advanced manufacturing processes and technologies to ensure the quality and reliability of this component 2.

Installation Process

Proper installation of the Tube Brace 4385411 is vital for its optimal performance and safety. The process involves securing the brace in the correct position within the truck’s frame, using specified fasteners and techniques. Attention to detail during installation ensures that the brace functions as intended, providing the necessary support and stability 3.

Maintenance and Troubleshooting

Regular inspection and maintenance of the Tube Brace 4385411 are recommended to ensure its continued effectiveness. Common issues may include corrosion or damage from impacts. Troubleshooting methods involve visual inspections, checking for secure fastenings, and addressing any signs of wear or damage promptly to maintain the brace’s integrity.

Benefits of Using Tube Brace 4385411

Incorporating the Tube Brace 4385411 into truck designs offers several advantages. These include enhanced durability of the vehicle, improved safety through better structural support, and potential cost savings over time due to reduced maintenance needs and extended component lifespan.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for reliability and performance. The company’s focus on technological advancement and customer satisfaction underscores its position in the market.

Applications and Use Cases

The Tube Brace 4385411 is particularly beneficial in heavy-duty and long-haul trucking applications where structural integrity is paramount. Its use can be seen in various commercial trucks, contributing to their durability and performance. Case studies and examples highlight the successful implementation of this component in enhancing truck reliability and efficiency.

Customer Reviews and Feedback

Feedback from truck operators, fleet managers, and mechanics who have used the Tube Brace 4385411 generally praises its durability and effectiveness in enhancing truck stability. Common criticisms may relate to installation challenges or specific application limitations, though these are often context-dependent.

Future Developments and Innovations

As technology advances, so too does the potential for improvements in tube brace design and functionality. Cummins is well-positioned to lead in these innovations, with ongoing research and development aimed at enhancing the performance, safety, and efficiency of commercial truck components. Future improvements may include materials with greater strength-to-weight ratios and designs that offer even more effective load distribution.

Role of Part 4385411 Tube Brace in Engine Systems

The 4385411 Tube Brace is an essential component in maintaining the structural integrity and operational efficiency of various engine systems. Its primary function is to provide support and stability to key components, ensuring they operate within their designed parameters.

Lubricating Oil Pump

In the context of the lubricating oil pump, the 4385411 Tube Brace plays a significant role in securing the pump’s housing and associated piping. By doing so, it helps maintain the alignment and stability of the pump, which is vital for consistent oil flow and pressure. This, in turn, ensures that all moving parts within the engine receive adequate lubrication, reducing wear and tear and enhancing the engine’s longevity.

The Tube Brace also aids in minimizing vibrations that can be transmitted through the oil lines. By dampening these vibrations, it contributes to the overall stability of the oil pump, allowing it to operate smoothly and efficiently. This is particularly important in high-performance engines where precision and reliability are paramount.

Furthermore, the 4385411 Tube Brace helps in maintaining the optimal positioning of the oil lines, preventing kinks or bends that could impede oil flow. This ensures that the lubricating oil pump can deliver the necessary volume of oil to critical engine components, such as bearings, pistons, and camshafts, under varying operating conditions.

In summary, the 4385411 Tube Brace is integral to the reliable operation of the lubricating oil pump by providing structural support, reducing vibrations, and ensuring proper alignment of oil lines. This contributes to the overall efficiency and durability of the engine system.

Conclusion

The Tube Brace 4385411 is a vital component in the structural integrity and operational efficiency of commercial trucks and engine systems. Its design, construction, and role in supporting key components contribute to the durability, safety, and performance of vehicles. Regular maintenance and proper installation are crucial for maximizing the benefits of this part. As technology advances, the potential for further improvements in tube brace design and functionality presents opportunities for enhanced vehicle performance and reliability.

-

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.