This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

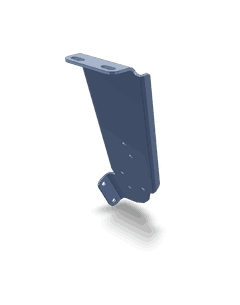

The 4389682 Tube Brace, manufactured by Cummins, is a component designed to enhance the structural integrity and operational efficiency of heavy-duty trucks. Cummins, a well-established name in the automotive and heavy-duty truck sectors, produces a range of parts aimed at enhancing vehicle performance and durability. This part contributes significantly to the structural integrity and operational efficiency of heavy-duty trucks.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce frames and chassis. They play a role in distributing stress and enhancing the overall rigidity of a vehicle’s structure. By connecting various parts of the frame, tube braces help maintain alignment and stability, which are important for the safe and efficient operation of a truck. Their presence can significantly influence a vehicle’s ability to withstand heavy loads and rough terrain 1.

Purpose of the 4389682 Tube Brace

The 4389682 Tube Brace is specifically designed to enhance the structural integrity and performance of heavy-duty trucks. It plays a role in reinforcing the truck’s frame, particularly in areas subjected to high stress. This reinforcement contributes to the truck’s durability, allowing it to handle heavier loads and operate more efficiently over time. By integrating this brace into the truck’s structure, Cummins aims to improve both the safety and longevity of the vehicle 2.

Key Features

The 4389682 Tube Brace boasts several key features that set it apart. It is constructed from high-strength steel, ensuring durability and resistance to wear. The design incorporates precise engineering to ensure a perfect fit within the truck’s frame. Additionally, the brace features a protective coating that enhances its resistance to corrosion, extending its lifespan even in harsh operating conditions 3.

Benefits

Utilizing the 4389682 Tube Brace offers several advantages. It improves the structural rigidity of the truck, which can lead to enhanced safety during operation. The brace also contributes to the truck’s ability to carry heavier payloads, potentially increasing its operational efficiency. Feedback from users indicates a noticeable improvement in truck performance and durability when this brace is installed.

Installation Considerations

Proper installation of the 4389682 Tube Brace is crucial for optimal performance. It is recommended to follow the manufacturer’s guidelines closely. This process may require specific tools and should be performed by individuals with the necessary expertise. Ensuring the brace is correctly aligned and securely fastened will help maintain the truck’s structural integrity and performance.

Troubleshooting and Maintenance

Regular maintenance and inspection of the 4389682 Tube Brace are recommended to ensure its continued effectiveness. Signs of wear, corrosion, or damage should be addressed promptly to prevent any compromise in the truck’s structural integrity. Troubleshooting may involve checking for proper alignment and ensuring all fasteners are secure. In cases of significant wear or damage, replacement may be necessary to maintain safety and performance standards.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industries. With a rich history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance parts. Their product range includes engines, filtration systems, and various components designed to enhance vehicle efficiency and durability. Cummins’ commitment to quality and performance is evident in their extensive lineup of products tailored for the demanding requirements of heavy-duty applications.

Role of Part 4389682 Tube Brace in Engine Systems

The 4389682 Tube Brace is an essential component in the structural integrity and performance optimization of various engine systems. When integrated with an aftercooler, the Tube Brace provides the necessary support to maintain the alignment and stability of the aftercooler within the engine assembly. This ensures efficient airflow and cooling, which are vital for the performance and longevity of the engine.

In turbocharged engine systems, the Tube Brace plays a significant role in supporting the intercooler. By securing the intercooler in place, it allows for optimal airflow through the cooling fins, enhancing the efficiency of the charge air cooling process. This results in denser air entering the combustion chamber, leading to improved engine performance and reduced thermal stress on engine components.

For engines equipped with exhaust gas recirculation (EGR) systems, the Tube Brace aids in the secure mounting of EGR coolers. This support is essential for maintaining the structural integrity of the EGR cooler, ensuring it functions correctly in reducing nitrogen oxides (NOx) emissions by cooling the recirculated exhaust gases before they enter the intake tract.

In diesel particulate filter (DPF) systems, the Tube Brace contributes to the stable installation of the DPF. This stability is important for the effective filtration of soot and other particulate matter from the exhaust gases, ensuring compliance with emissions regulations and promoting a cleaner operating environment.

Overall, the 4389682 Tube Brace is a fundamental component in enhancing the reliability and efficiency of various engine systems by providing the necessary structural support to critical components such as aftercoolers, intercoolers, EGR coolers, and DPFs.

Conclusion

The 4389682 Tube Brace by Cummins is a vital component for enhancing the structural integrity and performance of heavy-duty trucks and various engine systems. Its design and features contribute to the durability, safety, and efficiency of vehicles, making it an important part for those in the automotive and heavy-duty truck industries.

-

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.