This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

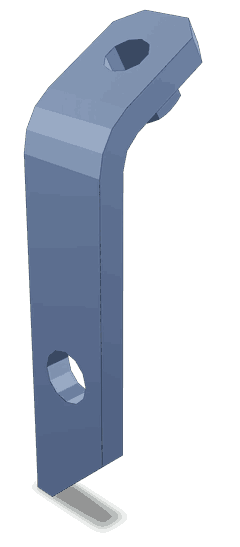

The Cummins 4933205 Wiring Brace is a component designed to enhance the electrical system of heavy-duty trucks. Its purpose is to support and organize wiring harnesses, ensuring they remain secure and protected from potential damage. This part plays a role in maintaining the integrity and efficiency of the truck’s electrical system 1.

Purpose and Function

The 4933205 Wiring Brace serves to support and organize the wiring harnesses within a truck’s electrical system. By securing the harnesses in place, it helps prevent them from coming into contact with moving parts or sharp edges, which could cause damage. This organization also aids in maintaining an efficient electrical system by ensuring that wires are routed correctly and do not interfere with other components 2.

Key Features

This Cummins part is constructed with durability and performance in mind. It is made from high-quality materials that can withstand the harsh conditions often encountered in heavy-duty truck environments. The design includes mounting options that allow for flexible installation, accommodating various truck models and configurations. Additionally, its unique attributes, such as corrosion resistance and robust construction, enhance its performance and longevity 3.

Benefits

Incorporating the 4933205 Wiring Brace into a truck’s electrical system offers several advantages. It improves wire management by keeping harnesses organized and secure, which can lead to a reduction in the risk of electrical faults. Furthermore, by protecting the wiring from physical damage, it enhances the overall durability of the electrical system, contributing to more reliable truck operation.

Installation and Compatibility

Proper installation of the 4933205 Wiring Brace is crucial for its effective function. It is designed to be compatible with a range of heavy-duty truck models, ensuring a fit that meets the specific requirements of each vehicle. Before installation, it is important to review the manufacturer’s guidelines to ensure compatibility and to follow the recommended procedures for a secure and efficient setup.

Maintenance and Troubleshooting

Regular maintenance of the 4933205 Wiring Brace is recommended to ensure its continued effectiveness. This includes checking for signs of wear or damage and ensuring that the wiring harnesses remain securely fastened. Common issues may include loose connections or damage to the brace itself, which can often be addressed through re-securing the harnesses or replacing the brace as necessary.

Safety Considerations

When installing or maintaining the 4933205 Wiring Brace, it is important to observe safety practices to prevent injury or damage. This includes ensuring that the truck’s electrical system is de-energized before beginning work and using appropriate personal protective equipment. Being aware of potential hazards, such as sharp edges or moving parts, and taking steps to mitigate them is also crucial.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established itself as a key player in the automotive industry, particularly in the production of components for heavy-duty trucks. Its commitment to innovation and quality has made it a trusted name among professionals in the field.

Role of Part 4933205 Wiring Brace in Engine Systems

The 4933205 Wiring Brace is a component that ensures the secure and organized routing of wiring within engine systems. Its primary function is to support and protect the wiring harness and electronic control module (ECM) wiring, which are vital for the operation of modern engines.

Harness Support

The wiring harness is a complex network of wires that transmit electrical signals and power to various engine components. The 4933205 Wiring Brace plays a role in maintaining the integrity of the harness by:

- Securing Wires: It holds the wires in place, preventing them from moving excessively during engine operation, which could lead to wear and potential failure.

- Organizing Bundles: It helps in neatly bundling wires together, reducing the risk of tangling and ensuring that the harness remains compact and manageable.

- Protecting from Vibration: By stabilizing the harness, it minimizes the impact of engine vibrations, which can otherwise cause damage to the wires over time.

ECM Wiring Protection

The electronic control module (ECM) is the brain of the engine, responsible for controlling various functions such as fuel injection, ignition timing, and emissions. The wiring that connects the ECM to other components must be protected to ensure reliable communication and power delivery. The 4933205 Wiring Brace contributes to this by:

- Shielding Sensitive Wires: It provides a protective barrier around the ECM wiring, shielding it from potential physical damage and environmental factors like moisture and heat.

- Maintaining Signal Integrity: By keeping the wiring organized and secure, it helps in maintaining the integrity of the electrical signals transmitted to and from the ECM, ensuring accurate and timely data exchange.

- Facilitating Maintenance: With the wiring brace in place, accessing and servicing the ECM wiring becomes easier, as the wires are less likely to be tangled or misplaced.

Conclusion

In summary, the 4933205 Wiring Brace is a key component in the efficient and reliable operation of engine systems, ensuring that both the harness and ECM wiring are well-supported and protected. Its role in maintaining the integrity of the electrical system is significant for the overall performance and reliability of these engines.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5613172, Engine: QSK95 CM2350 K143C.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.