This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

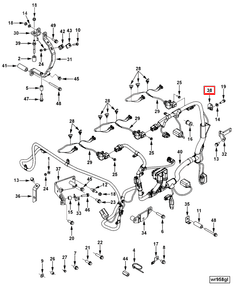

The Cummins 4933207 Wiring Brace is a component designed to support and organize the wiring harnesses in commercial trucks. Its role is to ensure the electrical system operates efficiently and remains protected from potential damage 1.

Purpose and Functionality

The Wiring Brace serves to secure and organize the wiring harnesses within a truck’s electrical system. By doing so, it helps prevent wires from coming into contact with moving parts or sharp edges, which could lead to abrasions or cuts. This organization also aids in maintaining the integrity of the electrical connections, ensuring consistent performance and reducing the likelihood of electrical faults 2.

Key Features

This Cummins part is constructed with durability in mind. It is made from high-quality materials that can withstand the rigors of commercial truck environments. The design of the brace allows for easy installation and adjustment, accommodating various wiring configurations. Additionally, its robust construction ensures long-lasting performance even under demanding conditions 3.

Benefits

Installing the Wiring Brace offers several advantages. It enhances wire management by keeping wires neatly organized and protected. This organization reduces the risk of electrical faults caused by wire damage. Furthermore, the brace contributes to the overall reliability of the truck’s electrical system by ensuring wires remain in their intended positions and are less likely to be affected by vibrations or movement.

Installation Considerations

When installing the 4933207, it is important to follow specific guidelines to ensure proper fit and function. Preparatory steps may include identifying the optimal location for the brace within the truck’s wiring system and ensuring all wiring is clean and free from damage. Tools required for installation may include basic hand tools for securing the brace in place. Common pitfalls to avoid during installation include over-tightening, which could damage wires, and improper placement, which could lead to ineffective wire protection.

Maintenance and Troubleshooting

Routine maintenance of the Wiring Brace involves periodic inspections to ensure it remains securely fastened and that wires show no signs of wear or damage. If issues such as wire abrasion or electrical shorts are detected, troubleshooting may involve adjusting the brace’s position or replacing damaged wiring. Regular checks help maintain the electrical system’s integrity and prevent potential failures.

Compatibility with Cummins Engines

The 4933207 is compatible with various Cummins engine models, including the QSC8.3 CM850 (CM2850) engines. It provides a robust framework that supports the wiring harness, ensuring that the electrical connections remain intact and secure, which is vital for the engine’s operational integrity and longevity.

Role in Engine Systems

This part plays a significant role in securing and organizing the harnesses and Electronic Control Module (ECM) Wiring. By providing a stable mounting point, it ensures that the harnesses remain in their designated positions, reducing the risk of chafing, abrasion, or disconnection. This stability is essential for maintaining the integrity of the electrical connections, which in turn ensures consistent performance and reliability of the engine system.

Conclusion

The 4933207 Wiring Brace is a key component in ensuring the efficient and reliable operation of engine systems by supporting and protecting critical wiring elements. Its durable construction, ease of installation, and maintenance benefits make it an essential part for commercial truck electrical systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.