This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

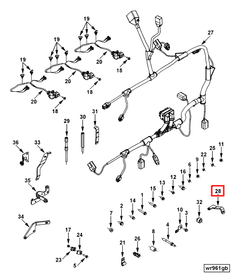

The Cummins 4945511 Wiring Brace is a component designed to enhance the electrical system of heavy-duty trucks. Its purpose is to support and organize the wiring harnesses, ensuring they remain secure and protected from potential damage. This part plays a role in maintaining the integrity and efficiency of the truck’s electrical system.

Purpose and Function

The 4945511 Wiring Brace serves to hold and organize the wiring harnesses within the truck’s engine compartment. By securing the wires in place, it helps prevent them from coming into contact with moving parts or sharp edges, which could lead to wear, fraying, or even complete failure of the wires. This organization also aids in maintaining a tidy engine compartment, which can simplify maintenance and troubleshooting processes 1.

Key Features

The design of the 4945511 Wiring Brace incorporates several features that enhance its functionality. It is constructed from durable materials that can withstand the harsh conditions found in a truck’s engine compartment. The brace offers various mounting options, allowing it to be securely attached in different configurations. Additionally, its design includes provisions for easy access to the wiring harnesses, facilitating maintenance and repairs 2.

Benefits

The use of the 4945511 Wiring Brace offers several advantages. It improves wire management by keeping the harnesses organized and protected. This reduces the risk of electrical faults that can arise from damaged or frayed wires. Furthermore, the brace contributes to the overall durability of the wiring system, ensuring reliable operation over the truck’s lifespan 3.

Installation Process

Installing the 4945511 Wiring Brace requires careful attention to detail. Begin by identifying the optimal location for the brace within the engine compartment. Securely mount the brace using the provided hardware, ensuring it is firmly in place. Route the wiring harnesses through the brace, making sure they are neatly organized and not under tension. Finally, double-check all connections and the brace’s stability before completing the installation 4.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 4945511 Wiring Brace, regular maintenance is recommended. Inspect the brace and wiring harnesses during routine engine checks for signs of wear or damage. Common issues may include loose mounting or worn harnesses, which can be addressed by tightening hardware or replacing damaged sections as needed.

Safety Considerations

When working with the 4945511 Wiring Brace, it is important to adhere to electrical safety practices. Ensure the truck’s battery is disconnected before beginning any work on the electrical system to prevent the risk of electric shock. Use appropriate personal protective equipment, such as insulated gloves and safety glasses, to protect against potential hazards.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality and innovation in the automotive and heavy-duty truck industry. The company’s extensive range of components, including the 4945511 Wiring Brace, reflects its dedication to enhancing the performance and reliability of vehicles.

Compatibility with Cummins Engines

The Wiring Brace part number 4945511, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is essential for securing and organizing wiring within the engine compartment, ensuring that electrical connections remain stable and protected.

QSC8.3 CM850 (CM2850) and QSL9 CM850 (CM2850)

The Wiring Brace part 4945511 fits seamlessly with the QSC8.3 CM850 (CM2850) and QSL9 CM850 (CM2850) engines. These engines are known for their robust performance and reliability, and the wiring brace helps maintain the integrity of the electrical system by keeping wires neatly arranged and preventing them from becoming dislodged.

QSC9 CM2250/QSL9 CM2250

The same wiring brace is also suitable for the QSC9 CM2250 and QSL9 CM2250 engines. These engines are part of Cummins’ lineup of high-performance diesel engines, and the wiring brace ensures that the complex wiring systems remain organized and secure, contributing to the overall efficiency and longevity of the engine.

QSL8.9 CM2150 L141

For the QSL8.9 CM2150 L141 engine, the Wiring Brace part 4945511 is equally important. This engine is designed for heavy-duty applications, and the wiring brace helps manage the extensive wiring that is necessary for its operation, ensuring that all electrical components function correctly and safely.

By using the Wiring Brace part 4945511, technicians and operators can ensure that the electrical systems of these Cummins engines remain in optimal condition, reducing the risk of damage and improving overall performance.

Role of Part 4945511 Wiring Brace in Engine Systems

The 4945511 Wiring Brace is a component in maintaining the integrity and functionality of various wiring systems within engine assemblies. This component plays a role in supporting and organizing the wiring harnesses and electronic control module (ECM) wiring, ensuring that these critical systems operate efficiently and reliably.

Integration with Wiring Harnesses

Wiring harnesses are complex networks of wires that transmit electrical signals and power throughout the engine system. The 4945511 Wiring Brace provides structural support to these harnesses, preventing them from sagging or becoming tangled. This support is vital for maintaining the proper spacing and alignment of wires, which helps to avoid potential short circuits and ensures consistent signal transmission. Additionally, the brace helps protect the wiring from physical damage caused by vibrations or contact with other engine components.

Support for Electronic Control Module Wiring

The electronic control module (ECM) is the brain of the engine, responsible for managing various functions such as fuel injection, ignition timing, and emissions control. The wiring connected to the ECM must be meticulously organized and protected to ensure accurate data transmission and reliable operation. The 4945511 Wiring Brace plays a key role in this by securing the ECM wiring in place, reducing the risk of wear and tear. This support is particularly important in high-vibration environments, where unsecured wiring can lead to intermittent connections or complete failures.

Engine Control Wiring Organization

Engine control wiring includes a variety of sensors and actuators that communicate with the ECM to monitor and adjust engine performance. The 4945511 Wiring Brace helps in organizing these wires, ensuring they are routed correctly and maintained in optimal condition. Proper organization prevents wires from interfering with each other, which can cause cross-talk and signal interference. Moreover, the brace aids in thermal management by allowing for adequate airflow around the wiring, which is essential for preventing overheating and ensuring the longevity of the engine control system.

Conclusion

In summary, the 4945511 Wiring Brace is a fundamental component in the engine system, providing essential support and organization for wiring harnesses, ECM wiring, and engine control wiring. Its role in maintaining the structural integrity and operational efficiency of these systems cannot be overstated.

-

Heavy Duty Truck Systems, Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ -

Light and Heavy Vehicle Technology, Fourth Edition, MJ Nunney, Butterworth-Heinemann, 2007

↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015

↩ -

Engine Testing: Theory and Practice: Third Edition, A.J. Martyr, SAE International, 2007

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.