This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

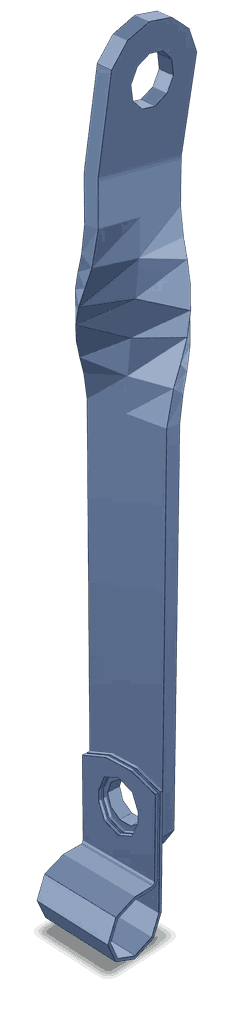

The 4947305 Tube Support Brace, manufactured by Cummins, is a component designed for heavy-duty truck applications. Cummins, a well-established name in the automotive industry, produces a range of parts that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part is significant within this context as it plays a role in maintaining the structural integrity and performance of trucks under demanding conditions.

Basic Concepts of Tube Support Braces

A Tube Support Brace is a structural component used in vehicle systems to reinforce and stabilize tubes and pipes. Its function is to provide additional support, reducing the risk of damage or failure under stress. In the context of a truck, these braces contribute to the overall structural integrity by ensuring that critical components remain securely in place, thereby enhancing the vehicle’s performance and longevity 1.

Purpose of the 4947305 Tube Support Brace

This part is specifically designed to support and stabilize tubes within the truck’s system. Its placement is strategic, interacting with other components to ensure that the tubes it supports are protected from excessive movement or stress. This support is vital for maintaining the efficiency and reliability of the truck’s systems, particularly under heavy-duty conditions.

Key Features

The 4947305 features a robust material composition, typically including high-strength steel, which ensures durability and resistance to wear. Its design incorporates precise engineering to fit securely around the tubes it supports, minimizing the risk of displacement. Additionally, the brace may include unique characteristics such as corrosion-resistant coatings or vibration-dampening features, which enhance its functionality in demanding environments.

Benefits

The advantages of using this Cummins part include improved durability of the truck’s components, enhanced performance through secure tube placement, and potential cost savings for fleet operators due to reduced maintenance needs and extended component lifespan. These benefits contribute to the overall efficiency and reliability of heavy-duty trucks.

Installation Process

Proper installation of this part involves several steps. Initially, the area around the tube that requires support should be cleaned and inspected for any damage. The brace should then be positioned according to the manufacturer’s guidelines, ensuring it is aligned correctly with the tube. Fasteners should be tightened to the specified torque settings to secure the brace in place without over-tightening, which could damage the tube or the brace itself. It is also important to verify that the brace does not interfere with other components and that all connections are secure.

Troubleshooting and Maintenance

Common issues with this part may include loosening of fasteners, corrosion, or physical damage. Regular inspections can help identify these issues early. Diagnostic tips include checking for signs of wear or corrosion, ensuring fasteners are tight, and looking for any signs of tube displacement. Maintenance practices should include cleaning the brace and its surroundings, reapplying corrosion-resistant coatings if necessary, and tightening fasteners as needed to ensure the brace remains effective.

Compatibility and Application

This part is designed for use with specific types of trucks and engine models. Its application is particularly beneficial in scenarios where tubes are subjected to high stress or vibration, such as in heavy-duty trucking operations. Ensuring compatibility with the truck’s make and model is crucial for optimal performance and longevity.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. Their contributions to heavy-duty truck components, including the 4947305, reflect their expertise and dedication to enhancing the performance and reliability of vehicles in demanding applications.

Tube Support Brace (Part 4947305) in Cummins Engines

The Tube Support Brace, identified by part number 4947305, is a component in the structural integrity of certain Cummins engines. This part is designed to provide support to the exhaust system, ensuring that the exhaust tubes remain securely in place and maintain their alignment.

Application in QSC8.3 CM850 (CM2850) and QSC9 CM2250/QSL9 CM2250

The Tube Support Brace is integral to the QSC8.3 CM850 (CM2850) and QSC9 CM2250/QSL9 CM2250 engines. In these engines, the brace is strategically positioned to support the exhaust tubes, which are subjected to significant thermal and mechanical stresses during operation.

By providing this support, the Tube Support Brace helps to mitigate the risk of exhaust tube misalignment, which can lead to performance issues and potential damage to the engine. The brace ensures that the exhaust system remains stable, contributing to the overall reliability and longevity of the engine.

In both the QSC8.3 CM850 (CM2850) and QSC9 CM2250/QSL9 CM2250 engines, the Tube Support Brace is a key component that plays a role in maintaining the structural integrity of the exhaust system. Its proper installation and maintenance are important for ensuring the efficient and reliable operation of these engines.

Role of Part 4947305 Tube Support Brace in Engine Systems

The part 4947305 is integral to maintaining the structural integrity and operational efficiency of various engine systems. It provides support to the tubes that connect key components, ensuring they remain securely in place under the dynamic conditions of engine operation.

Gauge System Integration

In the gauge system, the Tube Support Brace plays a role by stabilizing the tubes that carry fluids or gases to and from the sensors. This support ensures that the gauges receive accurate readings by maintaining consistent flow and pressure within the tubes. Without this brace, the tubes could shift or vibrate excessively, leading to inconsistent gauge readings and potential misdiagnosis of engine conditions.

Oil Level Monitoring

For the oil level monitoring system, the Tube Support Brace is important. It supports the tubes that connect the oil level sensor to the oil pan. This ensures that the sensor receives a steady stream of oil, allowing for precise measurement of the oil level. Proper support prevents the tubes from sagging or moving, which could otherwise result in inaccurate oil level readings. This accuracy is vital for maintaining optimal lubrication and preventing engine damage due to low oil levels.

Conclusion

In summary, the 4947305 Tube Support Brace is a key component in ensuring the reliability and accuracy of engine monitoring systems by providing necessary structural support to critical tubes. Its role in maintaining the structural integrity and performance of heavy-duty trucks and engines underscores its importance in automotive applications.

-

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.