This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

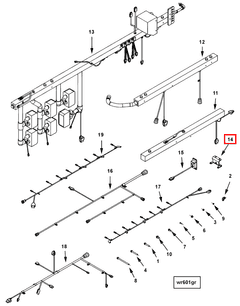

The 4951939 Wiring Support Brace, manufactured by Cummins, is a component designed to enhance the electrical system’s integrity in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part plays a role in maintaining the electrical system’s organization and safety 1.

Basic Concepts of Wiring Support Braces

A Wiring Support Brace is a structural component used in a vehicle’s electrical system to secure and organize wiring harnesses. Its function is to protect the wiring from physical damage, reduce the risk of electrical shorts, and ensure that the wiring remains in place under various driving conditions. This contributes to the overall performance and safety of the truck by maintaining the integrity of the electrical connections and preventing potential hazards associated with loose or damaged wiring 2.

Purpose of the 4951939 Wiring Support Brace

This part is specifically designed to secure and organize the wiring harnesses in a truck. By doing so, it helps in maintaining the electrical system’s efficiency and reliability. The brace ensures that the wiring is held firmly in place, reducing the likelihood of wires coming into contact with moving parts or sharp edges, which could lead to damage or electrical faults 3.

Key Features

The 4951939 is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operations. Its design includes features that allow for easy installation and adjustment, accommodating various wiring configurations. Additionally, the brace is engineered to provide maximum protection for the wiring, with a focus on durability and long-term performance 4.

Benefits

The use of the 4951939 offers several benefits. It improves wire management by keeping the wiring organized and secure, which can lead to easier troubleshooting and maintenance. The brace’s durable construction enhances the electrical system’s reliability, potentially contributing to the truck’s overall efficiency and safety. By protecting the wiring from physical damage, it also helps in preventing electrical issues that could arise from worn or damaged wires 1.

Installation Considerations

When installing the 4951939, it is important to follow guidelines and best practices to ensure proper fitment and function. Preparatory steps may include inspecting the wiring harnesses for any damage and ensuring they are routed correctly. The use of appropriate tools is recommended to secure the brace in place without causing damage to the wiring or surrounding components. Common pitfalls to avoid include over-tightening the brace, which could lead to damage, and not ensuring the wiring is properly secured within the brace 2.

Troubleshooting and Maintenance

For troubleshooting common issues related to the 4951939, it is advisable to inspect the brace and wiring regularly for signs of wear or damage. Maintenance tips include checking the securement of the wiring within the brace and ensuring there are no loose connections. Signs of wear or damage, such as frayed wires or a compromised brace, may require attention to prevent potential electrical issues 3.

Compatibility and Applications

The 4951939 is designed for use in specific types of trucks and models. Its application is focused on ensuring compatibility with the electrical systems of these vehicles, providing a secure and organized solution for wiring harnesses 4.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes components and systems that enhance the performance, efficiency, and reliability of heavy-duty vehicles.

Cummins Engine Wiring Support Brace 4951939

The Wiring Support Brace part number 4951939, manufactured by Cummins, is a component in the electrical infrastructure of several Cummins engine models. This part is designed to secure and stabilize the wiring harnesses within the engine compartment, ensuring that the electrical connections remain intact and protected from the vibrations and stresses encountered during engine operation.

Application in Cummins Engines

QSK60 and CM850 Series

The Wiring Support Brace 4951939 is integral to the QSK60 and CM850 series engines. These engines are known for their robust performance and reliability in various industrial and power generation applications. The brace helps maintain the integrity of the wiring systems, which is crucial for the efficient operation of these high-output engines.

MCRS Series

In the MCRS series, the Wiring Support Brace 4951939 plays a similar role. The MCRS engines are designed for heavy-duty applications, including marine and construction equipment. The brace ensures that the wiring harnesses are securely fastened, preventing potential damage that could lead to electrical failures or safety hazards.

Importance of the Wiring Support Brace

The proper installation of the Wiring Support Brace 4951939 is essential for the longevity and reliability of the engine’s electrical system. By providing a stable mounting point for the wiring harnesses, the brace helps to:

- Prevent wear and tear on the wiring due to engine vibrations.

- Maintain the integrity of electrical connections, reducing the risk of short circuits.

- Ensure compliance with safety standards by securing the wiring in place.

Installation Considerations

When installing the Wiring Support Brace 4951939, it is important to follow the manufacturer’s guidelines to ensure proper fit and function. This includes:

- Using the correct mounting hardware and securing the brace in the designated location.

- Ensuring that the wiring harnesses are properly routed and secured to the brace.

- Regularly inspecting the brace and wiring for signs of wear or damage.

By adhering to these guidelines, the Wiring Support Brace 4951939 will effectively support the electrical systems of the QSK60, CM850, and MCRS series engines, contributing to their overall performance and reliability.

Role of Part 4951939 Wiring Support Brace in Engine Systems

The 4951939 Wiring Support Brace is an integral component in the structural integrity and efficient operation of various engine systems. It provides essential support and organization for the wiring harness and electronic control module (ECM) wiring.

Harness Support

The wiring harness is a complex network of wires that transmit electrical signals and power throughout the engine system. The 4951939 Wiring Support Brace ensures that the harness is securely held in place, preventing it from coming into contact with moving parts or heat sources. This support minimizes the risk of wire damage, which can lead to electrical faults and system failures. Additionally, it helps in maintaining the optimal routing of the harness, which is vital for reducing electromagnetic interference and ensuring consistent signal transmission.

ECM Wiring Organization

The electronic control module (ECM) is the brain of the engine system, responsible for controlling various functions such as fuel injection, ignition timing, and emissions. The ECM wiring must be meticulously organized to avoid any potential short circuits or signal disruptions. The 4951939 Wiring Support Brace plays a significant role in this organization by keeping the ECM wiring neatly arranged and protected. This not only enhances the reliability of the ECM but also simplifies troubleshooting and maintenance procedures.

Conclusion

In summary, the 4951939 Wiring Support Brace is a key component in maintaining the structural and functional integrity of the engine’s electrical systems. Its role in supporting the wiring harness and organizing the ECM wiring ensures that the engine operates efficiently and reliably.

-

Trzesniowski, Michael. The Complete Vehicle. Springer Nature, 2023.

↩ ↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ ↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ ↩ -

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.