This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

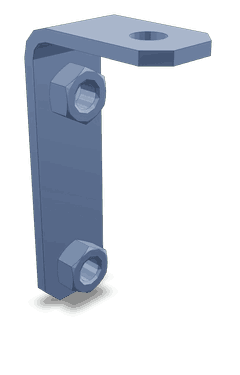

The Cummins 5267112 Wiring Brace is designed to enhance the electrical system of heavy-duty trucks by supporting and organizing wiring harnesses. This ensures they remain secure and undamaged during operation, maintaining the integrity and efficiency of the truck’s electrical system.

Purpose and Function

The Cummins 5267112 Wiring Brace holds and organizes wiring harnesses within a truck’s electrical system. By securing the harnesses, it prevents excessive movement or contact with other components, which could lead to wear, damage, or electrical faults. This organization ensures stable and reliable electrical connections, contributing to the vehicle’s overall performance and safety 3.

Key Features

This part is constructed from high-quality materials to withstand heavy-duty truck environments. It includes mounting points and secure clamps to hold wiring harnesses firmly in place. The brace is engineered for easy installation and compatibility with various truck models, enhancing its versatility 4.

Benefits

Installing the Cummins 5267112 Wiring Brace improves wiring management by keeping harnesses organized and protected, reducing the risk of electrical faults. This leads to enhanced reliability of the truck’s electrical system, ensuring consistent performance. Moreover, by preventing damage to the wiring, it contributes to the longevity and safety of the vehicle 1.

Installation Process

To install the Cummins 5267112 Wiring Brace, ensure the truck’s electrical system is powered down. Gather necessary tools, position the brace in the designated area, and use the provided mounting points to secure it. Ensure all wiring harnesses are properly routed through the brace and clamped securely. Double-check all connections to confirm they are tight and stable.

Troubleshooting Common Issues

Common issues with the 5267112 Wiring Brace may include loose connections or damage to the brace itself. If wiring harnesses appear loose, re-secure them using the clamps provided. Inspect the brace for any signs of wear or damage; if necessary, replace it to maintain the integrity of the electrical system. Regular checks can help identify and address these issues promptly.

Maintenance Tips

To ensure the continued effectiveness of the Cummins 5267112 Wiring Brace, regular maintenance is recommended. Inspect the brace and wiring harnesses periodically for signs of wear or damage. Clean the area around the brace to prevent the buildup of dirt or debris, which could affect performance. Ensure all connections remain secure and tight, and address any issues immediately to maintain the reliability of the electrical system.

Compatibility and Applications

The Cummins 5267112 Wiring Brace is designed for use in a variety of heavy-duty trucks. It is commonly applied in models where robust electrical system support is required. Its versatility makes it a valuable component across different truck makes and models, ensuring widespread application in the industry.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company offers a comprehensive product range, including engines, filtration, emissions solutions, and power systems, all designed to meet the demanding needs of various applications 2.

Wiring Brace Part 5267112 for Cummins Engines

The Wiring Brace part 5267112 is designed to maintain the integrity and organization of electrical wiring in specific Cummins engines, particularly the QSC9 CM2250 and QSL9 CM2250 engines. It ensures that the wiring remains secure and properly positioned, which is crucial in demanding environments to maintain the reliability and longevity of the electrical components.

Role of Part 5267112 Wiring Brace in Engine Systems

The 5267112 Wiring Brace is integral to maintaining the integrity and functionality of various engine systems. It supports and secures the wiring harnesses that connect different parts of the engine.

Air Intake Connection

In the air intake system, the 5267112 Wiring Brace ensures that the wiring associated with sensors and actuators remains taut and protected. This is particularly important for sensors that monitor air flow, temperature, and pressure. By keeping the wiring secure, the brace helps maintain consistent and accurate data transmission, which is vital for the engine control unit (ECU) to make precise adjustments to the air-fuel mixture 3.

Electronic Control Module (ECM) Wiring Harness

For the ECM wiring harness, the 5267112 Wiring Brace provides necessary support and organization. The ECM relies on a complex network of wires to communicate with various engine components, including the fuel injectors, ignition system, and emission controls. The brace helps prevent wire chafing and reduces the risk of electrical shorts, ensuring reliable communication between the ECM and other engine parts. This results in improved engine performance and efficiency 4.

Conclusion

The Cummins 5267112 Wiring Brace plays a significant role in maintaining the integrity and efficiency of heavy-duty truck electrical systems. By securing and organizing wiring harnesses, it prevents damage and ensures reliable electrical connections, contributing to the overall performance and safety of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ ↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.