This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

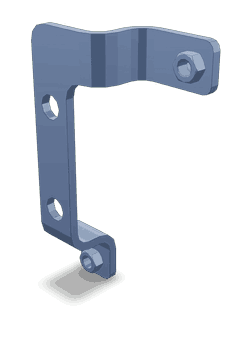

The 5313462 Tube Brace, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, specializes in diesel engines and related components. Tube braces, including the 5313462, play a role in reinforcing the structural framework of heavy-duty vehicles, contributing to their overall durability and performance 1.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to enhance rigidity and distribute loads more effectively across the chassis. By connecting various parts of the vehicle’s frame, tube braces help maintain the integrity of the structure under stress. This reinforcement is particularly important in commercial trucks, which often carry heavy loads and operate in demanding conditions 2.

Purpose of the 5313462 Tube Brace

The 5313462 Tube Brace is designed to enhance the structural integrity and operational efficiency of commercial trucks. It plays a role in supporting the frame and mitigating the effects of heavy loads and dynamic stresses encountered during operation. By providing additional support, this tube brace contributes to the vehicle’s durability, ensuring it can withstand the rigors of heavy-duty use 3.

Key Features

The 5313462 Tube Brace is constructed using high-strength materials, ensuring it can endure the stresses of commercial truck operations. Its design includes precise dimensions tailored to fit specific truck models, enhancing its effectiveness. Unique characteristics of this tube brace may include corrosion-resistant coatings or specialized mounting brackets, which contribute to its longevity and ease of installation.

Benefits

Utilizing the 5313462 Tube Brace offers several advantages. It enhances the structural rigidity of the truck, potentially increasing its payload capacity. This reinforcement also contributes to the safety of the vehicle by ensuring the frame remains stable under load. Additionally, the improved structural integrity can lead to increased efficiency and longevity of the truck, reducing the need for frequent repairs and replacements.

Installation Considerations

When installing the 5313462 Tube Brace, it is important to follow guidelines to ensure proper fitment and functionality. Preparatory steps may include cleaning the installation area and verifying that all mounting points are free of obstructions. The use of appropriate tools is recommended to secure the brace effectively. Common pitfalls to avoid during installation include over-tightening fasteners, which can lead to damage, and neglecting to check for proper alignment.

Troubleshooting and Maintenance

Regular inspection of the 5313462 Tube Brace is recommended to identify potential issues such as corrosion, fatigue, or signs of improper installation. Maintenance checks should include verifying the integrity of fasteners and ensuring there is no excessive wear or damage to the brace itself. Addressing these issues promptly can help maintain the effectiveness and longevity of the tube brace.

Cummins: Manufacturer Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of diesel and alternative fuel engines, as well as related technologies. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is committed to delivering high-quality components that enhance the performance and reliability of vehicles. Their expertise in engine and component manufacturing underscores the quality and reliability of the 5313462 Tube Brace 4.

Cummins Tube Brace 5313462 Compatibility

The Cummins Tube Brace part number 5313462 is designed to provide structural support and stability within the engine compartment of various Cummins engines. This part is crucial for maintaining the integrity of the engine’s framework and ensuring that all components are securely fastened.

Engine Compatibility

-

6B5.9 Series

- The Tube Brace 5313462 is specifically engineered to fit within the engine architecture of the 6B5.9 series. This engine series is known for its robust design and is commonly used in heavy-duty applications. The brace ensures that the engine remains securely mounted, reducing the risk of mechanical failure due to vibrations or impacts.

-

Other Cummins Engines

- While the Tube Brace 5313462 is primarily associated with the 6B5.9 series, it may also be compatible with other Cummins engines that share similar design parameters. Technicians and engineers should verify compatibility with specific engine models to ensure proper fitment and function.

Installation and Function

-

Mounting Points

- The Tube Brace 5313462 is typically installed at key mounting points within the engine bay. These points are strategically chosen to provide maximum support and stability. Proper installation is critical to ensure that the brace effectively performs its function.

-

Material and Durability

- Constructed from high-quality materials, the Tube Brace 5313462 is designed to withstand the rigors of heavy-duty use. Its durability ensures a long service life, reducing the need for frequent replacements and maintenance.

-

Role in Engine Performance

- By providing structural support, the Tube Brace 5313462 helps to maintain the alignment and positioning of engine components. This is essential for optimal engine performance and longevity. It also helps to mitigate the effects of engine vibrations, contributing to a smoother and more reliable operation.

Role of Part 5313462 Tube Brace in Accessory Support Systems

The 5313462 Tube Brace is an integral component in the accessory support system of various engine setups. Its primary function is to provide structural reinforcement and stability to the accessory support, which houses and supports various engine accessories such as alternators, power steering pumps, and air conditioning compressors.

Structural Reinforcement

In the accessory support system, the 5313462 Tube Brace ensures that the accessories remain securely in place under the dynamic conditions of engine operation. This reinforcement is essential for maintaining the alignment and operational integrity of these accessories. Without adequate support, accessories could shift or vibrate excessively, leading to potential failures or reduced efficiency.

Vibration Dampening

The Tube Brace also plays a significant role in dampening vibrations transmitted from the engine to the accessories. By absorbing and dissipating these vibrations, it helps in prolonging the lifespan of the accessories and ensuring smooth operation. This is particularly important in high-performance engines where vibrations are more pronounced.

Thermal Management

In some engine configurations, the 5313462 Tube Brace assists in thermal management by providing a stable framework that can help in the efficient routing of coolant lines or heat shields. This ensures that heat generated by the engine is effectively managed, preventing overheating of sensitive components.

Alignment and Spacing

Proper alignment and spacing of engine accessories are vital for their efficient operation. The Tube Brace helps in maintaining the correct distance between accessories, ensuring that belts or chains used to drive these components are properly tensioned. This is essential for the smooth transfer of power and reduces the risk of belt slippage or chain wear.

Integration with Other Systems

The 5313462 Tube Brace often integrates with other engine systems such as the exhaust system, intake manifold, and even the engine block itself. This integration provides a cohesive support structure that enhances the overall rigidity and performance of the engine.

Conclusion

In summary, the 5313462 Tube Brace is a key component in the accessory support system, offering structural reinforcement, vibration dampening, thermal management, and precise alignment of engine accessories. Its role is fundamental in ensuring the reliable and efficient operation of the engine and its accessories.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Bosch, R. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5676982.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.