This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5316080 Wiring Brace is a component designed to enhance the electrical system’s reliability and organization in commercial trucks. Its role is to secure and manage wiring harnesses, ensuring they remain in place and protected from potential damage during operation.

Purpose and Function

This Cummins part serves to organize and secure wiring harnesses within the truck’s electrical system. By keeping wires neatly arranged and firmly in place, it helps prevent chafing, abrasion, and other forms of damage that could lead to electrical faults. This component contributes to maintaining the integrity of the electrical connections, which is vital for the truck’s overall performance and safety 1.

Key Features

The design of the 5316080 incorporates several features that enhance its functionality. Constructed from durable materials, it is built to withstand the rigors of commercial truck environments. The brace offers various mounting options, allowing for flexible installation in different truck models. Its design also includes provisions for easy access to wiring harnesses, facilitating maintenance and repairs 2.

Benefits

Installing the 5316080 offers several advantages. It improves wire management by keeping harnesses organized and protected, which can reduce the risk of electrical faults. The brace’s robust construction ensures durability, even in harsh operating conditions. Additionally, by securing wiring harnesses, it helps maintain consistent electrical performance, contributing to the truck’s reliability 3.

Installation and Compatibility

Proper installation of this part involves securing it in the designated location within the truck’s electrical system. This process may require specific tools or equipment, depending on the truck model. It is important to follow the manufacturer’s guidelines to ensure correct installation. Compatibility information, including specific truck models and engine types, should be consulted to ensure the brace is suitable for the intended application 4.

Maintenance and Troubleshooting

Routine maintenance of the 5316080 involves inspecting it for signs of wear or damage and ensuring that wiring harnesses remain securely fastened. Common issues may include loose connections or damaged wires, which can be addressed by tightening fasteners or repairing harnesses as needed. Regular checks help identify potential problems early, ensuring the electrical system’s continued reliability.

Safety Considerations

When working with the 5316080, it is important to observe electrical safety guidelines. This includes ensuring the truck’s electrical system is de-energized before beginning any work to prevent the risk of electric shock. Proper handling procedures should be followed to avoid damage to the brace or wiring harnesses. Additionally, wearing appropriate personal protective equipment (PPE) is recommended to ensure safety during installation and maintenance tasks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product offerings include a wide range of engines and components designed to meet the demanding requirements of commercial vehicles.

Compatibility with Various Engines

The Wiring Brace part number 5316080, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is essential for securing and organizing wiring within the engine compartment, ensuring that electrical connections remain stable and protected during operation.

Compatibility with Specific Engines

- L8.9G: The Wiring Brace 5316080 is engineered to fit seamlessly with the L8.9G engine, providing robust support for the wiring harness and ensuring that all electrical components are securely fastened.

- CMOH2.0: For the CMOH2.0 engine, the part 5316080 plays a crucial role in maintaining the integrity of the wiring system. Its design allows for easy installation and adjustment, accommodating the specific layout of the engine’s wiring.

- L125B: The L125B engine also benefits from the use of the Wiring Brace 5316080. This part ensures that the wiring is neatly organized and secured, preventing any potential damage that could arise from movement or vibration during engine operation.

Grouping of Engines

When considering the compatibility of the Wiring Brace 5316080, it is important to note that it is designed to work with these specific engines individually. However, the commonality in their design allows for a straightforward installation process across these models. The part’s versatility ensures that it can be adapted to the unique requirements of each engine type, providing a reliable solution for wiring management.

Role of Part 5316080 Wiring Brace in Engine Systems

The 5316080 Wiring Brace is an essential component in maintaining the integrity and functionality of various engine systems. It plays a significant role in supporting and securing the wiring harness, which is vital for the proper operation of the engine.

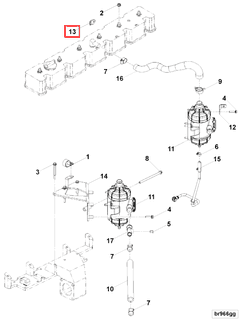

Breather System Integration

In the breather system, the 5316080 Wiring Brace ensures that the wiring associated with the breather components remains organized and protected. This is particularly important as the breather system manages the ventilation of the crankcase, helping to release pressure and prevent the buildup of contaminants. Secure wiring is necessary to avoid any interference with the breather’s operation, ensuring that the system can effectively vent gases and maintain a clean crankcase environment.

Crankcase Ventilation

The crankcase ventilation system relies on precise wiring to monitor and control various sensors and actuators. The 5316080 Wiring Brace helps in maintaining the structural integrity of these wires, preventing them from coming into contact with moving parts or high-temperature areas within the engine compartment. This protection is essential for the reliable performance of the crankcase ventilation system, which is responsible for expelling harmful gases and maintaining optimal pressure levels within the crankcase.

Harness Organization

Within the engine compartment, the wiring harness can become complex, with numerous wires connecting different components. The 5316080 Wiring Brace plays a key role in organizing these wires, reducing the risk of tangling or damage. This organization is vital for the harness’s durability and ensures that all electrical connections remain secure and functional. Proper harness management also aids in easier diagnosis and maintenance, as technicians can more readily access and inspect the wiring.

Electronic Control Module (ECM) Wiring

The Electronic Control Module (ECM) is the brain of the engine, relying on a network of wires to communicate with various sensors and actuators. The 5316080 Wiring Brace supports these critical connections by providing a stable and secure pathway for the ECM wiring. This ensures that the ECM receives accurate data from sensors and can effectively control engine functions. Secure wiring is essential for the ECM’s reliability, as any disruption in these connections can lead to misfires, inefficient fuel consumption, or even engine failure.

Conclusion

In summary, the 5316080 Wiring Brace is integral to the proper functioning of several engine systems. By securing and organizing the wiring, it ensures that components like the breather, crankcase ventilation, harness, and ECM operate efficiently and reliably.

-

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Huang, Matthew. Vehicle Crash Dynamics. CRC Press, 2002.

↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.