This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

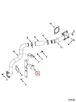

The Cummins 5398000 Tube Brace is a component designed to enhance the structural integrity of heavy-duty trucks. Its role is significant within the context of heavy-duty truck components, providing support and stability to various parts of the vehicle. This overview will delve into the specifics of the Tube Brace, exploring its purpose, function, features, benefits, installation guidelines, maintenance recommendations, and the background of its manufacturer, Cummins Inc.

Purpose and Function

The Cummins 5398000 Tube Brace serves to reinforce the structural framework of heavy-duty trucks. It plays a role in supporting other components, ensuring that the vehicle maintains its structural integrity under various operating conditions. By providing additional support, the Tube Brace contributes to the overall performance and durability of the truck, allowing it to withstand the stresses and strains associated with heavy-duty operations 1.

Key Features

The design and construction of the Cummins 5398000 Tube Brace are tailored to meet the demanding requirements of heavy-duty trucks. It is composed of high-strength materials, ensuring durability and resistance to wear and tear. The dimensions of the Tube Brace are optimized to fit specific truck models, enhancing its functionality. Unique attributes, such as its robust construction and precise engineering, contribute to its effectiveness in supporting the truck’s structure 2.

Benefits

The Cummins 5398000 Tube Brace offers several advantages, including improved structural stability and enhanced safety. By reinforcing the truck’s framework, it helps to prevent structural failures that could lead to accidents. Additionally, the Tube Brace may contribute to increased operational efficiency by ensuring that the truck’s components remain securely in place, reducing the risk of malfunctions or breakdowns. These benefits translate to better performance and longevity of the truck, making it a valuable addition to heavy-duty vehicles 3.

Installation and Compatibility

Proper installation of the Cummins 5398000 Tube Brace is crucial to ensure its effectiveness. Guidelines for installation should be followed to integrate the Tube Brace seamlessly into the truck’s structure. Compatibility with specific truck models is important, and any prerequisites or considerations for installation should be taken into account to ensure a successful integration 4.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the longevity and effectiveness of the Cummins 5398000 Tube Brace. Regular inspections and checks can help identify any issues early on, allowing for timely repairs or replacements. Common issues that may arise include wear and tear or damage from heavy-duty operations. Suggested troubleshooting steps can help address these issues, ensuring that the Tube Brace continues to function optimally 5.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established a strong reputation for excellence. The company’s product range includes a variety of automotive components, each designed to meet the rigorous demands of heavy-duty applications. Cummins’ dedication to quality is evident in the design and construction of the 5398000 Tube Brace, reflecting the company’s expertise and commitment to providing durable and reliable solutions for the automotive industry 6.

Role of Part 5398000 Tube Brace in Engine Systems

The 5398000 Tube Brace is instrumental in enhancing the structural integrity and operational efficiency of various engine systems. In the context of plumbing systems, this component ensures that fluid pathways remain secure and unobstructed. It supports pipes and hoses, minimizing the risk of vibrations that could lead to leaks or failures. This is particularly important in high-pressure systems where even minor disruptions can have significant consequences.

In Exhaust Recirculation (EGR) systems, the Tube Brace plays a key role in maintaining the alignment and stability of the EGR valve and associated piping. By securing these components, it helps ensure that the recirculated exhaust gases are efficiently mixed with the incoming air, optimizing combustion and reducing emissions. This not only enhances engine performance but also contributes to environmental compliance.

For Air Intake systems, the Tube Brace supports the air ducts and intake manifolds, ensuring they remain in optimal position. This stability is essential for maintaining consistent airflow into the engine, which is vital for combustion efficiency and overall engine performance. By securing these components, the Tube Brace helps prevent issues such as air leaks or restricted airflow, which can negatively impact engine operation 7.

Conclusion

The Cummins 5398000 Tube Brace is a critical component for enhancing the structural integrity and operational efficiency of heavy-duty trucks and engines. Its robust design, precise engineering, and compatibility with various truck models make it a valuable addition to any heavy-duty vehicle. Proper installation, regular maintenance, and understanding its role in different engine systems are essential for maximizing the benefits of this Cummins part.

-

Tyres Suspension and Handling Second Edition, John C Dixon, SAE International, 1996

↩ -

Aerodynamics of Road Vehicles: Fifth Edition, Thomas Schuetz, SAE International, 2016

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩ -

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ -

Fault Code Troubleshooting Manual, QSB6.7 CM2350 B145, Bulletin Number 5411276

↩ -

Cummins Inc. Company Overview, Cummins Inc., 2023

↩ -

Engine Systems and Components, Cummins Technical Manual, 2021

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.