This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

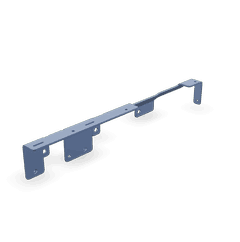

The Cummins 5399132 Tube Brace is a component designed to enhance the structural integrity of commercial trucks. Its role is significant within the context of truck components, providing support and stability to various parts of the vehicle. This overview will delve into the specifics of the tube brace, its function, and its importance in truck design and operation.

Basic Concepts of Tube Braces

Tube braces are structural elements used in vehicle construction to reinforce frames and chassis. They function by distributing stress and enhancing the rigidity of the vehicle’s structure. In the context of trucks, tube braces contribute to the overall durability and performance by supporting critical components and ensuring the vehicle can withstand the rigors of heavy-duty use 1.

Purpose of the 5399132 Tube Brace

This Cummins part plays a specific role in the operation and structural integrity of a truck. It supports other components by providing additional strength to the truck’s frame, which is particularly important under heavy loads or in challenging driving conditions. This support contributes to the truck’s durability and safety, ensuring that the vehicle can maintain its structural integrity over time.

Key Features

The design and construction of the 5399132 Tube Brace include several features that enhance its performance and longevity. It is made from high-strength materials, ensuring it can withstand significant stress. The dimensions of the brace are tailored to fit specific truck models, providing optimal support. Unique characteristics, such as corrosion-resistant coatings, further enhance its durability in various environments 2.

Benefits of Using the 5399132 Tube Brace

Incorporating this Cummins part into truck designs offers several advantages. It improves structural rigidity, which is vital for maintaining the truck’s performance under load. Enhanced safety is another benefit, as the brace helps prevent structural failures that could lead to accidents. Additionally, the brace may contribute to operational efficiency by ensuring the truck’s frame remains stable, potentially reducing maintenance needs and downtime.

Installation Process

Proper installation of the 5399132 Tube Brace involves several steps to ensure optimal performance and integration with the truck’s structure. Preparatory steps include cleaning the installation area and ensuring all necessary tools are available. The installation process should follow manufacturer guidelines to avoid issues such as misalignment or insufficient tightening. Best practices include double-checking all connections and ensuring the brace is securely fastened.

Troubleshooting Common Issues

Common problems associated with tube braces include corrosion, fatigue, and improper installation. Corrosion can be addressed through regular inspections and the application of protective coatings. Fatigue may require replacement of the brace if significant wear is detected. Improper installation can often be corrected by re-evaluating the installation process and making necessary adjustments to ensure the brace is properly secured.

Maintenance Tips

Regular maintenance practices are crucial for ensuring the longevity and effectiveness of the 5399132 Tube Brace. Inspection routines should be established to check for signs of wear, corrosion, or damage. Cleaning the brace and its surrounding areas can prevent buildup that may lead to corrosion. Knowing when to consider replacement is also important, as a compromised brace may no longer provide the necessary support.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation in automotive components. With a history of producing reliable and high-performance parts, Cummins has built a reputation for excellence. Its product range includes a variety of components designed to enhance the efficiency, durability, and safety of commercial trucks 3.

Compatibility with Cummins Engines

The Tube Brace part number 5399132, manufactured by Cummins, is designed to provide structural support and stability to various engine configurations. This part is integral in maintaining the integrity of the engine’s framework, ensuring that the engine remains securely mounted and operational under various conditions.

ISL9.5 CM2880 L138 Engines

The Tube Brace part 5399132 is compatible with the ISL9.5 CM2880 L138 engines, which are known for their robust performance and reliability in heavy-duty applications. This part plays a role in these engines by:

- Providing Structural Support: Ensuring the engine’s components are properly aligned and secured.

- Enhancing Stability: Reducing vibrations and movements that could potentially lead to mechanical failures.

- Facilitating Maintenance: Allowing for easier access to other engine components during service and repair operations.

Grouping of Engines

The Tube Brace part 5399132 is engineered to fit seamlessly within the design parameters of the ISL9.5 CM2880 L138 engines, ensuring compatibility across these models. This part is a component in maintaining the overall structural integrity of these engines, which are often used in demanding environments such as construction, mining, and transportation industries.

Conclusion

The Cummins 5399132 Tube Brace is a vital component in the structural integrity and performance of commercial trucks. Its design, featuring high-strength materials and corrosion-resistant coatings, ensures durability and longevity. Proper installation and regular maintenance are essential for maximizing its benefits, which include improved structural rigidity, enhanced safety, and operational efficiency. As a part of Cummins’ commitment to quality and innovation, the 5399132 Tube Brace plays a crucial role in supporting the demanding requirements of heavy-duty truck applications.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Bennett, S. (2012). Modern Diesel Technology Light Duty Diesels. Cengage Learning.

↩ -

Hu, H., Baseley, S. J., & Song, X. (2021). Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.