This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

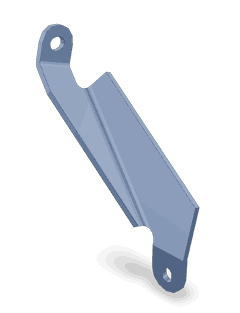

The Cummins 3102342 Starting Motor Brace is designed to enhance the reliability and performance of the starting system in heavy-duty trucks. It provides structural support to the starting motor, ensuring stable and efficient engine starts under various operating conditions.

Purpose and Function

The Starting Motor Brace secures the starting motor in place, minimizing movement and vibration during engine start-up. This support helps maintain the integrity of the electrical connections and mechanical components involved in the starting process 1.

Key Features

This Cummins part is constructed with high-quality materials for durability and performance. It features robust mounting points for secure attachment to the engine block and precise alignment features for optimal installation. The design may include vibration dampening materials or reinforced sections to enhance effectiveness 2.

Benefits

Using the 3102342 Starting Motor Brace reduces wear and tear on the starting motor caused by vibrations, leading to a longer lifespan. It also minimizes vibrations during engine start-up, enhancing overall engine performance and reliability 3.

Installation Process

Installing the Starting Motor Brace involves positioning it on the engine block, using provided mounting hardware, and tightening bolts to specified torque settings. Verify the alignment of the starting motor with the brace for optimal performance. Specific tools may be required for access and correct torque settings.

Troubleshooting Common Issues

Common issues with Starting Motor Braces include loose mounting points, misalignment, or damage. These problems may result in increased vibrations or unreliable engine starts. Inspect mounting points for tightness, realign the brace if necessary, and replace any damaged components.

Maintenance Tips

Regular maintenance of the 3102342 Starting Motor Brace is important for longevity and performance. Inspect the brace during routine engine checks for signs of wear or damage. Clean the brace and its mounting points to remove debris. Follow the manufacturer’s recommended inspection intervals.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines. With a strong reputation for quality and innovation, Cummins has been a trusted name in the automotive industry. The company is committed to providing reliable and efficient power solutions that meet the demands of various applications, including heavy-duty trucks.

Cummins Engine Compatibility with Part 3102342

The 3102342 Starting Motor Brace is compatible with various Cummins engine models, including the ISX CM570. It is designed to securely mount the starting motor, providing the necessary support to withstand high torque during engine startup.

ISX CM570

The ISX CM570 engine benefits from the robust design of the Starting Motor Brace. This engine requires a reliable mounting system to ensure the starting motor operates smoothly and effectively. The brace maintains the alignment and integrity of the starting motor, contributing to the engine’s overall performance and longevity.

Grouping of Engines

The 3102342 Starting Motor Brace is engineered to fit seamlessly into various engine configurations, ensuring universal application across different models. Its design allows for easy installation and compatibility with the mounting points and structural requirements of multiple engine types.

Understanding the Role of Part 3102342 Starting Motor Brace in Engine Systems

The 3102342 Starting Motor Brace is integral to the assembly and functionality of various engine systems. Its primary role is to provide structural support and stability to the starting motor, ensuring efficient and reliable engine start-ups.

Integration with Starting Motor Mounting

When installed, the Starting Motor Brace securely attaches to the starting motor mounting points. This connection is vital for maintaining the alignment and positioning of the starting motor. The brace absorbs and distributes mechanical stresses generated during engine start-up, preventing undue strain on the motor and its mounting brackets.

Enhanced Stability and Performance

By reinforcing the starting motor’s structural integrity, the Starting Motor Brace contributes to the overall stability of the engine system. This enhanced stability ensures that the starting motor operates within its designed parameters, leading to consistent and reliable performance. The brace also helps reduce vibrations that can occur during engine start-up, which can otherwise lead to premature wear and potential failures in the starting motor or its connections.

Support During Engine Start-Up

During the engine start-up phase, the Starting Motor Brace supports the starting motor as it engages with the flywheel. This support is essential for smooth and efficient engine cranking, which is a precursor to a successful engine start. The brace ensures that the starting motor can deliver the necessary torque without experiencing excessive movement or misalignment, which could otherwise hinder the start-up process.

Contribution to Engine Longevity

The presence of the Starting Motor Brace contributes to the longevity of the engine system by providing additional support and stability. This reduces the likelihood of starting motor failures and related issues, which can be both costly and time-consuming to repair. By ensuring that the starting motor operates under optimal conditions, the brace helps maintain the overall health and efficiency of the engine.

Conclusion

The 3102342 Starting Motor Brace is a key component that enhances the performance, stability, and longevity of engine systems by providing essential support to the starting motor during operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.