This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

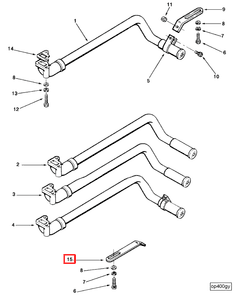

The Suction Connection Brace, identified by part number 3011051, is a component manufactured by Cummins, a leading name in diesel engine technology. This brace is designed specifically for heavy-duty trucks, where it serves to reinforce the connection points within the suction system. Its role is pivotal in ensuring the structural integrity and operational efficiency of the truck’s suction system 2.

Function and Operation

The Suction Connection Brace operates by providing a stable and secure connection between various components within the truck’s suction system. It plays a role in maintaining the structural integrity of these connections, which is vital for the system’s overall performance. Additionally, the brace facilitates efficient fluid dynamics by ensuring that the connections remain tight and secure, thereby minimizing the risk of leaks and ensuring that the suction system operates at optimal efficiency 1.

Key Features

The design of the Suction Connection Brace incorporates several elements that contribute to its durability and effectiveness. Constructed from materials that offer high corrosion resistance, the brace is well-suited for the demanding environments typical of heavy-duty truck operations. Its robust construction ensures that it can withstand the stresses and vibrations associated with truck use, providing a reliable connection that supports the efficient operation of the suction system 2.

Benefits

The incorporation of the Suction Connection Brace into a truck’s suction system offers several advantages. It enhances the reliability of the suction system by providing a secure and stable connection, which is crucial for the system’s performance. Additionally, the brace contributes to the increased longevity of connected components by reducing the stress and wear that can occur at connection points. This, in turn, supports the overall efficiency of the truck’s system, potentially leading to improved performance and reduced maintenance needs 1.

Installation Considerations

Proper installation of the Suction Connection Brace is crucial for ensuring its optimal performance and integration with the truck’s existing systems. It is important to follow manufacturer guidelines closely, ensuring that all connections are secure and that the brace is correctly positioned to support the suction system effectively. Attention to detail during installation can prevent common issues and ensure that the brace functions as intended 2.

Maintenance and Troubleshooting

Regular maintenance of the Suction Connection Brace is recommended to ensure continued reliable operation. This includes checking for signs of wear or corrosion and ensuring that all connections remain secure. Troubleshooting common issues, such as leaks or loose connections, can often be addressed by re-tightening connections or applying a compatible sealant. Regular inspections and maintenance can help identify potential issues before they lead to more significant problems 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in the realm of diesel engine manufacturing. The company’s commitment to innovation is evident in its continuous development of new technologies and solutions that enhance the performance, efficiency, and reliability of its products 2.

Cummins Suction Connection Brace Part 3011051

The Cummins Suction Connection Brace part number 3011051 is a critical component in the engine assembly, ensuring the structural integrity and proper alignment of the suction connection system. This part is designed to fit seamlessly with various Cummins engines, providing a robust connection point that supports the suction manifold and associated components 2.

Application in Cummins Engines

The Suction Connection Brace part 3011051 is engineered to be compatible with a range of Cummins engines, including but not limited to:

-

K19 Series: This part is specifically designed to fit within the K19 engine family, ensuring that the suction connection system remains stable and properly aligned during operation. The K19 engines are known for their reliability and efficiency, and the Suction Connection Brace plays a vital role in maintaining these characteristics by preventing any misalignment or undue stress on the suction components 2.

-

Other Cummins Engines: While the K19 series is a primary focus, the part 3011051 is also compatible with other Cummins engines that share similar design parameters and structural requirements. This ensures that the brace can be utilized across a broader range of engine models, providing a consistent and reliable solution for suction connection integrity 2.

The design of the Suction Connection Brace part 3011051 ensures that it can be easily integrated into the engine assembly process, providing a secure and durable connection point for the suction manifold. This is crucial for maintaining the overall performance and longevity of the engine, as it helps to prevent any potential issues that could arise from a poorly supported suction system 2.

Conclusion

The Suction Connection Brace, part number 3011051, is an essential component in the assembly and functionality of various engine systems. It is strategically positioned to connect and support the lubricating oil tube, ensuring a secure and stable connection to the oil pan. This brace plays a significant role in maintaining the integrity of the oil circulation system within the engine.

By firmly attaching to the oil pan, the suction connection brace helps in stabilizing the lubricating oil tube, which is vital for the consistent flow of oil throughout the engine. This consistent flow is necessary for the proper lubrication of moving parts, reducing friction and wear. The brace’s design allows it to withstand the pressures and vibrations inherent in engine operation, ensuring that the connection between the oil tube and the pan remains intact.

Furthermore, the brace contributes to the overall structural stability of the oil pan itself. The oil pan, which houses the engine’s oil supply, must be securely supported to prevent any potential leaks or damage. The suction connection brace aids in distributing the forces exerted on the oil pan, enhancing its durability and reliability.

In summary, the Suction Connection Brace is a key element in the engine’s oil management system. Its role in connecting and supporting the lubricating oil tube to the oil pan is fundamental to the efficient operation and longevity of the engine 2.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.