This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

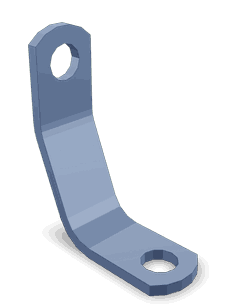

The Tube Brace 111670 by Cummins is a component designed to enhance the structural integrity of heavy-duty trucks. A tube brace generally serves to reinforce the frame of a vehicle, providing additional support and stability. This Cummins part is engineered to meet the demanding requirements of heavy-duty truck operations, ensuring that the vehicle can withstand significant stress and loads 1.

Purpose and Function

The Tube Brace 111670 plays a specific role in the structural framework of a truck by reinforcing critical areas of the chassis. It contributes to the overall stability and durability of the vehicle by distributing loads more evenly across the frame. This reinforcement helps to prevent frame twisting and bending, which can occur under heavy loads or during rough terrain navigation 2.

Key Features

This part is constructed from high-strength steel, which provides excellent durability and resistance to wear and tear. Its design includes precise welding points and robust connections to ensure a secure fit within the truck’s frame. Additionally, the tube brace features a corrosion-resistant coating, which enhances its longevity by protecting against rust and environmental damage 3.

Benefits

Incorporating the Tube Brace 111670 into a truck’s frame offers several advantages. It improves load distribution, which is vital for maintaining structural integrity under heavy loads. The enhanced rigidity provided by the tube brace can lead to increased safety by reducing the risk of frame failure. Furthermore, the improved structural support can contribute to more efficient operation by ensuring that the truck’s frame remains stable and aligned, potentially leading to better fuel efficiency and reduced maintenance costs.

Installation Considerations

When installing the Tube Brace 111670, it is important to follow specific guidelines to ensure optimal performance. Preparatory steps include cleaning the installation area to remove any dirt or debris that could affect the weld quality. The necessary tools for installation typically include a welding torch, alignment tools, and possibly a frame straightening tool if adjustments are needed. Proper alignment is crucial to ensure that the tube brace integrates seamlessly with the existing frame structure.

Maintenance and Troubleshooting

Regular maintenance checks are recommended to ensure the Tube Brace 111670 remains in optimal condition. Inspection routines should include looking for signs of wear, corrosion, or damage to the brace and its connections. Common issues may include loose welds or corrosion at attachment points, which should be addressed promptly to prevent further degradation. Routine maintenance can help identify potential problems early, ensuring the continued safety and performance of the truck.

Compatibility and Applications

The Tube Brace 111670 is designed for use in specific types of trucks and models. It is commonly applied in heavy-duty applications where additional frame support is beneficial. Depending on the truck model, modifications or additional components may be required to facilitate proper installation. It is important to consult the manufacturer’s guidelines to ensure compatibility and correct installation procedures.

Manufacturer Overview - Cummins

Cummins is a well-established manufacturer with a strong reputation in the heavy-duty truck industry. The company has a history of producing reliable and high-quality components, including engine parts, filtration systems, and structural components like the Tube Brace 111670. Cummins’ commitment to innovation and quality ensures that their products meet the rigorous demands of heavy-duty applications, providing truck operators with dependable performance and durability.

Tube Brace Compatibility with Cummins Engines

The Tube Brace part number 111670, manufactured by Cummins, is designed to fit a variety of Cummins engines. This component is crucial for maintaining the structural integrity of the engine by providing support and stability to the engine’s tubes. Below is a detailed breakdown of the engines that are compatible with this Tube Brace:

K19 Series

- K19

- KTA19GC

- KTA19GC CM558

M11 Series

- M11 CELECT PLUS

- M11 MECHANICAL

N14 Series

- N14 CELECT

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

QSK19 Series

- QSK19 CM2350 K105

- QSK19 CM500

- QSK19 CM850 MCRS

QSK19T Series

- QSK19T CM876 N102

NH/NT Series

- NH/NT 855

This Tube Brace is engineered to ensure compatibility across these engine models, providing a reliable solution for maintaining the engine’s structural framework.

Role of Part 111670 Tube Brace in Engine Systems

The Part 111670 Tube Brace is an integral component in the structural integrity and efficient operation of various engine systems. Its application spans across multiple subsystems, enhancing both performance and reliability.

Breather & Filler and Related Components

In the breather & filler system, the Tube Brace provides essential support to the breather mounting tube and the crankcase breather. This support ensures that the breather system maintains optimal alignment and structural stability, which is vital for the efficient venting of gases from the crankcase. Additionally, it aids in the secure attachment of the engine breather and oil filler, contributing to a leak-free environment.

Engine Control Module and Fuel Systems

For the engine control module (ECM) and fuel systems, the Tube Brace plays a supportive role in the fuel pump coupling and fuel pump plumbing. By providing a stable mounting point, it ensures that the fuel lines and couplings remain securely in place, reducing the risk of fuel leaks and maintaining consistent fuel delivery to the engine.

Oil Systems

In oil systems, the Tube Brace is utilized in the oil fill arrangement and oil gauge setup. It ensures that the oil fill tube and gauge are properly aligned and supported, facilitating accurate oil level readings and secure oil filling processes. This is particularly important in high-performance engines where precise oil levels are essential for optimal lubrication.

Pressure and Manifold Systems

The Tube Brace is also integral in pressure tube manifolds, where it supports the manifold structure, ensuring even distribution of pressure across the system. This is crucial for components like the rocker lever housing and support, where consistent pressure is required for reliable operation.

Turbocharger Systems

In turbocharger applications, the Tube Brace is employed in turbocharger mounting, plumbing, and vent plumbing. It provides the necessary support for turbocharger water supply mounting, ensuring that the turbocharger remains securely attached and aligned. This support is vital for maintaining turbocharger efficiency and preventing performance issues due to misalignment.

Valve Cover & Filler and Vent Systems

For the valve cover & filler and vent systems, the Tube Brace supports the vent and mounting tube, as well as the vernier throttle. This support ensures that the vent tubes remain properly aligned, facilitating efficient venting of gases from the valve cover and maintaining stable throttle operation.

Jacobs Brake and Throttle Accessory Support

Lastly, in systems involving the Jacobs brake and throttle accessory support, the Tube Brace provides the required structural support. This ensures that these components remain securely in place, contributing to the overall reliability and performance of the engine system.

Conclusion

The Tube Brace 111670 by Cummins is a vital component for enhancing the structural integrity and performance of heavy-duty trucks. Its robust design, compatibility with various Cummins engines, and role in multiple engine subsystems make it an essential part for maintaining the reliability and efficiency of heavy-duty vehicles.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavy-duty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Cummins Inc. Operation and Maintenance Manual for X12 CM2350 X144C. Bulletin Number 5659744.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.