This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

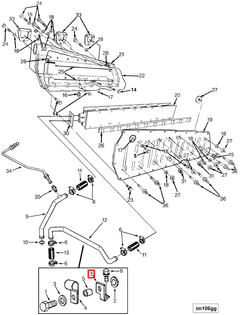

The Cummins 3015437 Tube Brace is a component designed to enhance the structural integrity of commercial trucks. It serves a specific role in reinforcing the truck’s frame, which is vital for maintaining the vehicle’s durability and safety during operation 1.

Purpose and Function

The Tube Brace plays a role in reinforcing the truck’s frame by providing additional support to critical areas that may be subject to stress and strain during operation. This reinforcement helps in enhancing the overall durability of the truck and ensures that it can withstand the rigors of heavy-duty use. By stabilizing the frame, the Tube Brace contributes to the safety of the vehicle, reducing the risk of structural failure under load 2.

Key Features

The Cummins 3015437 Tube Brace is constructed using high-strength materials, which are chosen for their durability and resistance to wear and tear. Its design includes specific dimensions and a robust construction that allows it to effectively support the truck’s frame. Unique attributes of the Tube Brace, such as its precise fit and engineered strength, contribute to its effectiveness in reinforcing the vehicle’s structure 3.

Benefits

The installation of the Tube Brace provides several advantages. It improves the load-bearing capacity of the truck, allowing it to handle heavier loads with greater confidence. The brace also offers resistance to stress and fatigue, which are common issues in heavy-duty applications. Furthermore, by reinforcing the frame, the Tube Brace contributes to the overall longevity of the vehicle, potentially reducing the need for repairs and replacements over time.

Installation Process

Proper installation of the Cummins 3015437 Tube Brace involves several steps. It is important to use the necessary tools and follow recommended procedures to ensure that the brace is securely fitted. Precautions should be taken to avoid damage to the truck’s frame and to ensure that the brace is aligned correctly for maximum effectiveness.

Maintenance and Inspection

Routine inspection and maintenance of the Tube Brace are important to ensure its continued effectiveness. Regular checks for signs of wear, such as corrosion or damage, should be conducted. Recommended inspection intervals should be adhered to, and any necessary maintenance procedures should be performed to keep the brace in optimal condition.

Troubleshooting Common Issues

Common problems associated with the Tube Brace may include corrosion, loose fittings, or structural damage. Identifying these issues early on is important for maintaining the integrity of the truck’s frame. Recommended corrective actions may involve tightening fittings, applying protective coatings to prevent corrosion, or replacing damaged components.

Safety Considerations

When working with the Tube Brace, it is important to follow safety protocols and best practices. This includes proper handling during installation and maintenance, as well as adhering to recommended procedures to minimize the risk of injury or accidents. Safety equipment should be used as necessary to protect individuals working on the vehicle.

Cummins Overview

Cummins Inc. is a well-established company with a history of providing high-quality components for the commercial truck industry. The company’s product offerings include a wide range of parts designed to enhance the performance and reliability of trucks. Cummins’ reputation for manufacturing durable and effective truck components is supported by its commitment to quality and innovation in the industry.

Conclusion

The Cummins 3015437 Tube Brace is a critical component for enhancing the structural integrity and operational efficiency of commercial trucks. Its role in reinforcing the truck’s frame and supporting critical engine components is indispensable for the overall performance, durability, and safety of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.