This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3035607 Tube Brace is a component designed to enhance the structural integrity and performance of heavy-duty trucks. Its role is significant in maintaining the robustness of truck chassis and ensuring the safe operation of various truck systems.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce the chassis and frame. They contribute to distributing loads more evenly across the vehicle’s structure, which can help in reducing stress on individual components and improving overall durability. In the context of heavy-duty trucks, tube braces contribute to the vehicle’s ability to handle heavy loads and rough terrain by providing additional support to critical areas of the chassis 1.

Purpose of the 3035607 Tube Brace

The 3035607 Tube Brace is specifically designed to support the structural framework of heavy-duty trucks. It reinforces the chassis, which can help in maintaining the alignment and integrity of other components under stress. By providing additional support, this tube brace contributes to the truck’s performance by ensuring that the chassis remains stable and resistant to deformation during operation.

Key Features

The 3035607 Tube Brace is constructed from high-strength materials, which are chosen for their durability and resistance to wear. Its design includes precise dimensions and fittings that ensure a secure attachment to the truck’s chassis. Unique characteristics of this tube brace may include its specific shape and the use of advanced manufacturing techniques that enhance its performance and longevity.

Benefits of Using the 3035607 Tube Brace

Incorporating the 3035607 Tube Brace into truck designs can lead to several advantages. These include enhanced durability of the chassis, improved safety by maintaining structural integrity under load, and potential increases in operational efficiency due to reduced chassis flex and improved component alignment.

Installation Considerations

Proper installation of the 3035607 Tube Brace is important for ensuring its effectiveness. Guidelines for installation include verifying compatibility with the truck model, ensuring correct placement according to the manufacturer’s specifications, and using appropriate securing methods to maintain a firm attachment to the chassis.

Troubleshooting and Maintenance

Regular inspection of the 3035607 Tube Brace can help in identifying common issues such as wear, corrosion, or damage. Maintenance practices to ensure its longevity include cleaning, checking for secure attachment, and addressing any signs of wear or damage promptly to prevent further deterioration.

Compatibility and Application

The 3035607 Tube Brace is designed for use in specific heavy-duty truck models. Its application is tailored to meet the structural reinforcement needs of these vehicles, contributing to their performance and durability in various operating conditions.

Cummins: A Brief Overview

Cummins Inc. is a company with a long history in the manufacturing of diesel engines and related technologies. Its expertise extends to the heavy-duty truck sector, where it provides a range of components and systems designed to enhance the performance, efficiency, and reliability of trucks. Cummins’ commitment to innovation and quality has established it as a reputable name in the automotive industry 2.

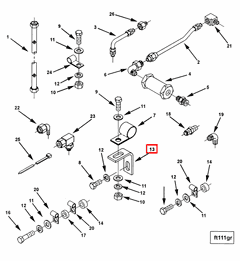

Tube Brace Part 3035607 in Cummins Engines

The Tube Brace part number 3035607, manufactured by Cummins, is a component in maintaining the structural integrity of specific Cummins engines. This part is designed to provide support and stability to the engine’s tubing system, ensuring that the engine operates smoothly and efficiently.

Application in N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Tube Brace part 3035607 plays a role in securing the tubing that carries various fluids and gases throughout the engine. This part helps in preventing any unwanted movement or vibration that could potentially lead to wear and tear or even engine failure. Its placement is important, as it must withstand the high pressures and temperatures inherent in engine operation.

Application in NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Tube Brace part 3035607 is integral to the engine’s design. This part ensures that the tubing system remains aligned and secure, which is vital for the efficient transfer of fluids and gases. The NH/NT 855 engines, known for their robust performance, rely on this brace to maintain the structural integrity of the engine’s tubing system, ensuring longevity and reliability.

Grouping of Engines

Both the N14 MECHANICAL and NH/NT 855 engines benefit from the Tube Brace part 3035607 in similar ways. The commonality lies in the need for a reliable support system for the engine’s tubing. This part is important in preventing any misalignment or movement that could compromise the engine’s performance. By grouping these engines, it is evident that the Tube Brace part 3035607 is a key component in maintaining the structural integrity of the tubing system across different engine models.

Role of Part 3035607 Tube Brace in Engine Systems

The 3035607 Tube Brace is an integral component in various engine systems, providing support and stability to multiple parts. Its applications span across several critical areas within the engine assembly, ensuring efficient operation and durability.

Air Compressor Upfit Kit

In the air compressor upfit kit, the Tube Brace secures the air compressor to the engine block, minimizing vibrations and ensuring stable operation. This stability is vital for consistent air compression, which is necessary for efficient engine performance.

Air Intake Manifold and Intake Manifold

For both the air intake manifold and the intake manifold, the Tube Brace plays a role in maintaining the structural integrity of the manifold. It ensures that the manifold remains securely attached to the engine block, preventing leaks and ensuring optimal airflow into the engine cylinders.

Bleed Tube Mounting and Check Valve Mounting

In systems involving bleed tube mounting and check valve mounting, the Tube Brace provides the necessary support to these components. This support is essential for maintaining the correct pressure and flow within the system, which is crucial for the engine’s overall efficiency.

Breather Location and Fuel Bypass Mounting Tube

At the breather location and for the fuel bypass mounting tube, the Tube Brace helps in securing these components in place. This is important for preventing oil leaks and ensuring that the fuel bypass system operates correctly, contributing to the engine’s smooth running.

EBM: Tubing and EBM: Plumbing, Fuel

In the context of EBM (Engine Bay Management) tubing and plumbing, particularly for fuel systems, the Tube Brace ensures that the fuel lines are securely held in place. This is important for maintaining the integrity of the fuel delivery system, preventing leaks, and ensuring consistent fuel supply to the engine.

Front Water Crossover Tube and Front Water Tube

For the front water crossover tube and front water tube, the Tube Brace provides the necessary support to maintain the correct flow of coolant. This is essential for effective engine cooling, preventing overheating, and ensuring the engine operates within optimal temperature ranges.

Fuel Supply Tube and Fuel Tube

In fuel supply tube and fuel tube applications, the Tube Brace ensures that these tubes are held firmly in place. This is crucial for maintaining the integrity of the fuel delivery system, preventing leaks, and ensuring a consistent fuel supply to the engine.

Mounting Fuel Bypass Tube and Plumbing (Aftercooler Water, Fuel, Fuel Supply)

For the mounting fuel bypass tube and various plumbing applications (aftercooler water, fuel, fuel supply), the Tube Brace provides the necessary support to these critical components. This support is essential for maintaining the correct flow and pressure within these systems, contributing to the engine’s overall performance and reliability.

Step White Smoke Kit and Supply Check Valve Mounting

In the step white smoke kit and supply check valve mounting, the Tube Brace ensures that these components are securely attached. This is important for maintaining the correct operation of these systems, which are vital for the engine’s efficient running and emission control.

Thermostat Housing and Water Manifold

For the thermostat housing and water manifold, the Tube Brace provides the necessary support to ensure these components remain securely in place. This is essential for maintaining the correct flow of coolant and ensuring the engine operates within optimal temperature ranges.

Water Transfer Tube

Finally, in the water transfer tube application, the Tube Brace ensures that this tube is held firmly in place. This is crucial for maintaining the correct flow of coolant, contributing to effective engine cooling and overall engine performance.

Conclusion

The Cummins 3035607 Tube Brace plays a significant role in enhancing the structural integrity and performance of heavy-duty trucks and Cummins engines. Its applications across various engine systems highlight its importance in ensuring efficient operation, durability, and reliability. Proper installation, maintenance, and understanding of its role in engine systems are crucial for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.