This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

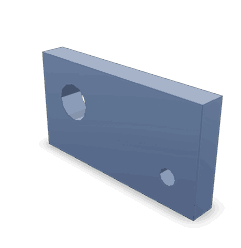

The 3820897 Tube Brace, manufactured by Cummins, is a component designed for heavy-duty trucks. It is part of a broader range of products aimed at enhancing the performance and durability of heavy-duty vehicles. Understanding the role and functionality of this part is important for maintaining and optimizing the structural integrity of trucks.

Basic Concepts of Tube Braces

A tube brace is a structural component used in vehicle construction to reinforce the frame and chassis. It functions by distributing stress and providing additional support to critical areas, thereby contributing to the overall stability and performance of the vehicle. In the context of heavy-duty trucks, tube braces play a significant role in ensuring that the vehicle can withstand the rigors of heavy loads and rough terrain 1.

Purpose of the 3820897 Tube Brace

The 3820897 Tube Brace is specifically designed to enhance the structural stability of heavy-duty trucks. It supports other components by reinforcing the frame, which helps in maintaining the alignment and integrity of the truck’s chassis. This reinforcement is particularly important in areas that are prone to stress and wear, ensuring that the truck can operate efficiently and safely over extended periods 2.

Key Features

This Cummins part is constructed from high-strength steel, which provides durability and resistance to corrosion. Its design includes precise welding and a robust framework that ensures it can handle significant loads without deformation. Additionally, the brace features a streamlined shape that minimizes aerodynamic drag, contributing to fuel efficiency. These characteristics distinguish it from other tube braces on the market 3.

Benefits

Using the 3820897 Tube Brace offers several advantages. It improves structural rigidity, which is crucial for the safe operation of heavy-duty trucks. Enhanced safety is another benefit, as the brace helps prevent frame failure under stress. Furthermore, the improved structural integrity can lead to increased operational efficiency, as the truck is better equipped to handle heavy loads and challenging conditions 4.

Installation Considerations

When installing the 3820897 Tube Brace, it is important to follow specific guidelines to ensure proper integration with the truck’s frame. Preparatory steps include cleaning the installation area and ensuring that all mounting points are free of debris. The necessary tools for installation typically include a torque wrench, welding equipment, and appropriate fasteners. Common pitfalls to avoid include improper alignment and insufficient tightening of fasteners, which can compromise the effectiveness of the brace.

Troubleshooting and Maintenance

Common issues with the 3820897 Tube Brace may include corrosion, wear, and loose fasteners. Regular inspections can help identify these problems early. Maintenance practices should include cleaning the brace to prevent corrosion, checking for signs of wear, and ensuring that all fasteners are secure. Addressing these issues promptly can help maintain the longevity and optimal performance of the tube brace.

Compatibility and Application

The 3820897 Tube Brace is designed for use in specific models of heavy-duty trucks. It is commonly applied in trucks that require additional frame reinforcement for heavy-duty operations. Notable applications include long-haul trucking and construction vehicles, where the brace has been shown to enhance durability and performance.

Cummins: Manufacturer Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its high-quality diesel engines and components. The company has a long history of innovation and reliability, providing a wide range of products for heavy-duty trucks. Cummins’ reputation is built on its commitment to producing durable, efficient, and high-performing components that meet the demanding needs of the heavy-duty truck market.

Tube Brace Part 3820897 Compatibility with Cummins Engines

The Tube Brace part 3820897, manufactured by Cummins, is a critical component designed to provide structural support and stability to the engine’s framework. This part is integral to maintaining the integrity of the engine’s internal components and ensuring optimal performance across various engine models.

L10 MECHANICAL

In the L10 MECHANICAL engine, the Tube Brace part 3820897 is meticulously engineered to fit into the engine’s architecture, providing essential support to the engine’s tubes and other critical components. Its placement is crucial for maintaining the alignment and stability of the engine, ensuring that it operates smoothly and efficiently.

M11 CELECT PLUS and M11 MECHANICAL

For both the M11 CELECT PLUS and M11 MECHANICAL engines, the Tube Brace part 3820897 serves a similar function. It is designed to fit seamlessly into the engine’s design, offering robust support to the tubes and other structural elements. This ensures that the engine maintains its structural integrity and performs reliably, regardless of the operating conditions.

The Tube Brace part 3820897 is a versatile component that is compatible with multiple Cummins engine models, including the L10 MECHANICAL, M11 CELECT PLUS, and M11 MECHANICAL. Its design and placement are critical for the overall performance and longevity of the engine, making it an essential part for maintaining the engine’s operational efficiency.

Role of Part 3820897 Tube Brace in Engine Systems

The 3820897 Tube Brace is an essential component in maintaining the structural integrity and efficient operation of various engine systems. Its primary function is to provide support and stability to the fuel and emissions systems, ensuring that these components operate within their designed parameters.

Support for Fuel Systems

In fuel systems, the 3820897 Tube Brace plays a significant role in supporting the fuel line kit and fuel plumbing. By securing the fuel lines, it prevents undue stress and potential damage from vibrations or movement, which can lead to fuel leaks or inefficient fuel delivery. This support is particularly important in high-performance engines where fuel lines are subjected to greater stress.

Integration with Fuel Pump Plumbing

When it comes to fuel pump plumbing, the 3820897 Tube Brace ensures that the connections between the fuel pump and the fuel lines remain secure. This is vital for maintaining consistent fuel pressure and flow, which are critical for engine performance and efficiency. The brace helps to absorb vibrations that could otherwise cause the fuel pump connections to loosen over time.

Enhancing Emissions System Performance

The emissions rebuild kit is another area where the 3820897 Tube Brace contributes significantly. By providing a stable platform for emissions components, it ensures that these systems can function effectively. This is particularly important for components like the catalytic converter and oxygen sensors, which require precise positioning and minimal movement to operate correctly.

General Plumbing Support

Beyond specific systems, the 3820897 Tube Brace offers general support for various plumbing components within the engine bay. Whether it’s supporting hoses, pipes, or other fluid lines, the brace helps to maintain the integrity of these systems by preventing wear and tear from constant engine vibrations.

Conclusion

In summary, the 3820897 Tube Brace is a versatile component that enhances the reliability and performance of fuel and emissions systems by providing necessary support and stability. Its role in securing and stabilizing these components ensures that the engine operates efficiently and reliably.

-

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Sander, Frank. Diesel Mechanics, First Edition. Global Media, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.