This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Tube Brace 3916418, manufactured by Cummins, is a component designed to enhance the structural integrity of commercial trucks. This part is integral to maintaining the robustness and reliability of trucks, particularly those subjected to heavy loads and challenging terrains. Cummins, a renowned manufacturer in the automotive industry, produces this tube brace as part of their commitment to providing high-quality components for commercial vehicles 1.

Basic Concepts of Tube Braces

Tube braces are structural components used in vehicle construction to reinforce the frame and chassis. They play a role in distributing stress and enhancing the overall stability and durability of the vehicle. By connecting various parts of the truck’s frame, tube braces help to maintain alignment and structural integrity under various driving conditions 2.

Purpose of the 3916418 Tube Brace

The 3916418 Tube Brace is specifically designed to provide additional support to the truck’s frame. It plays a role in reinforcing the structure, allowing the truck to handle heavier loads and navigate rough terrain more effectively. This enhancement in structural support contributes to the truck’s overall performance and longevity 3.

Key Features

The 3916418 Tube Brace is constructed from high-strength steel, ensuring durability and resistance to wear and tear. Its design includes precise welding and robust connections to critical points on the truck’s frame. These features not only enhance the brace’s effectiveness but also ensure it can withstand the rigors of commercial use. Additionally, the brace is engineered to fit seamlessly with Cummins trucks, ensuring compatibility and ease of installation.

Benefits of Using the 3916418 Tube Brace

Incorporating the 3916418 Tube Brace into truck design offers several advantages. It contributes to improved durability by reinforcing the truck’s frame, which is particularly beneficial for vehicles that frequently carry heavy loads. Enhanced safety is another benefit, as the brace helps to maintain the truck’s structural integrity, reducing the risk of frame failure. Furthermore, the increased durability and safety can lead to potential increases in operational efficiency, as trucks are less likely to require repairs or downtime.

Installation Considerations

When installing the 3916418 Tube Brace, it is important to follow guidelines and best practices to ensure proper integration with the truck’s frame. Preparatory steps include cleaning the installation area and ensuring all necessary tools are available. Common pitfalls to avoid during installation include improper alignment and insufficient tightening of connections, which can compromise the brace’s effectiveness. Careful attention to these details will help ensure a successful installation.

Troubleshooting and Maintenance

Common issues that may arise with the 3916418 Tube Brace include corrosion and wear at connection points. Regular inspections can help identify these problems early, allowing for timely repairs or replacements. Recommended maintenance practices include cleaning the brace and its connections, applying protective coatings to prevent corrosion, and ensuring all connections remain tight and secure. These practices will help ensure the longevity and optimal performance of the tube brace.

Cummins: Manufacturer Overview

Cummins has a long-standing reputation for manufacturing high-quality automotive components. Their expertise in the commercial truck industry is demonstrated through a commitment to innovation and reliability. Cummins continues to lead the way in producing components that not only meet but exceed industry standards, ensuring their products contribute to the efficiency, safety, and durability of commercial vehicles 4.

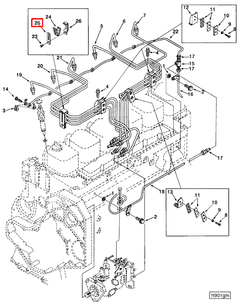

Tube Brace Part 3916418 in Cummins Engines

The Tube Brace part 3916418, manufactured by Cummins, is a critical component in the assembly of various Cummins engines. This part is designed to provide structural support and stability to the engine’s tubing system, ensuring that the engine operates smoothly and efficiently.

Application in Specific Engines

-

6B5.9 Engine Series

The Tube Brace part 3916418 is integral to the 6B5.9 engine series. It is used to secure and stabilize the tubing that carries essential fluids and gases within the engine. This ensures that the engine’s performance is not compromised due to vibrations or misalignments in the tubing system.

-

Grouped Engines

Cummins has designed the Tube Brace part 3916418 to be compatible with a range of engines within the same family. This allows for easier maintenance and repair, as the same part can be used across multiple engine models. This compatibility is particularly beneficial for fleets and operators who use multiple Cummins engines, as it simplifies inventory management and reduces downtime.

Importance of the Tube Brace

The Tube Brace part 3916418 plays a role in maintaining the integrity of the engine’s tubing system. By providing a stable framework, it helps to prevent wear and tear on the tubing, which can lead to leaks and other issues. This, in turn, contributes to the longevity and reliability of the engine.

Installation and Maintenance

Proper installation of the Tube Brace part 3916418 is essential to ensure that it performs its function effectively. This typically involves securing the brace to the engine’s frame using bolts or other fasteners. Regular maintenance checks should be conducted to ensure that the brace remains in good condition and is properly aligned. Any signs of wear or damage should be addressed promptly to prevent potential issues with the engine’s tubing system.

Role of Part 3916418 Tube Brace in Engine Systems

The 3916418 Tube Brace is an integral component in the structural integrity and efficient operation of various engine systems. Its primary function is to provide support and stability to the injector fuel supply tube, ensuring that it remains securely in place during engine operation. This is particularly important in high-stress environments where vibrations and mechanical forces could otherwise dislodge or damage the fuel supply tube.

In the context of engine plumbing, the Tube Brace plays a significant role by maintaining the alignment and integrity of the fuel lines. This ensures a consistent and reliable fuel supply to the engine, which is essential for optimal performance and efficiency. The brace helps in mitigating the effects of engine vibrations, which can otherwise lead to fuel line fatigue or disconnection.

Furthermore, the Tube Brace contributes to the overall safety of the fuel system by preventing potential leaks that could arise from unsecured or damaged fuel lines. By keeping the fuel lines stable and well-positioned, it reduces the risk of fuel spills or fires, thereby enhancing the safety of the engine system.

Conclusion

The 3916418 Tube Brace is a key component in maintaining the structural integrity and operational reliability of both truck frames and engine systems. Its role in supporting critical components such as the injector fuel supply tube and stabilizing the fuel lines is essential for the efficient and safe operation of the engine. Proper installation and regular maintenance of this Cummins part are crucial to ensure its effectiveness and longevity.

-

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Cummins. Fault Code Troubleshooting Manual. Bulletin Number 6314884.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.