3944698

Tube Brace

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3944698 Tube Brace, manufactured by Cummins, is designed to enhance the structural integrity and performance of commercial trucks. This article provides a comprehensive overview of this part, its function, key features, benefits, and maintenance suggestions.

Understanding Tube Braces

A Tube Brace is a structural component used in the chassis and frame of commercial trucks. It consists of a tubular metal piece that connects two or more points on the frame, providing additional support and rigidity. Tube Braces help distribute loads more evenly across the frame, reducing stress on individual components and enhancing overall durability 1.

Purpose of the 3944698 Tube Brace

The 3944698 Tube Brace by Cummins is specifically engineered to reinforce the frame of heavy-duty trucks. It plays a role in maintaining the structural integrity of the truck’s chassis by providing additional support where it is needed most. This reinforcement helps the truck withstand the rigors of heavy-duty operations, including hauling heavy loads and navigating rough terrain 2.

Key Features

- Material: Constructed from high-strength steel to ensure durability and longevity.

- Design: Tubular design allows for efficient load distribution and minimal weight addition.

- Installation: Designed for easy integration with the truck’s existing frame structure.

- Compatibility: Engineered to fit specific models of Cummins-powered trucks, ensuring precise fitment and function.

Benefits

- Enhanced Structural Integrity: Provides additional support to the truck’s frame, helping to prevent deformation and damage under heavy loads.

- Improved Safety: Contributes to the overall safety of the vehicle by maintaining frame stability.

- Increased Longevity: Helps extend the lifespan of the truck’s chassis by reducing wear and stress on critical components.

- Better Performance: Ensures the truck can perform optimally under demanding conditions.

Troubleshooting and Maintenance

- Regular Inspections: Conduct routine checks for signs of wear, corrosion, or damage.

- Tightening Connections: Ensure all connections are secure and tightened to the manufacturer’s specifications.

- Corrosion Protection: Apply protective coatings or treatments to prevent rust and corrosion.

- Replacement: If any damage is detected, replace the Tube Brace promptly to maintain the structural integrity of the truck.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong commitment to innovation and quality, Cummins provides reliable and efficient solutions for a wide range of industries, including commercial trucking. Their products are known for their durability, performance, and efficiency 3.

Application in Specific Cummins Engines

ISC CM554 and ISL CM554 Engines

In the ISC CM554 and ISL CM554 engines, the 3944698 Tube Brace plays a pivotal role in securing the engine’s exhaust system. It helps to maintain the alignment and positioning of the exhaust tubes, which is crucial for optimal performance and longevity of the engine. The Tube Brace ensures that the exhaust system does not experience undue stress or movement, which could lead to wear and potential failures.

QSC8.3 CM554 and QSL9 CM554 Engines

For the QSC8.3 CM554 and QSL9 CM554 engines, the 3944698 Tube Brace is similarly vital. It provides the necessary support to the engine’s internal and external components, ensuring that they remain in their intended positions. This is particularly important in these engines, where the design and operational demands require robust structural integrity to handle the high stresses and vibrations typical of heavy-duty applications.

Role of 3944698 Tube Brace in Engine Systems

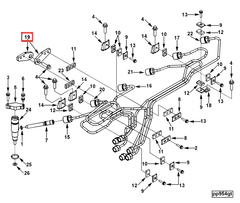

The 3944698 Tube Brace is an essential component in the structural integrity and efficient operation of engine systems, particularly in relation to the Injector and Injector Fuel Supply Tube.

Integration with Injector

The Injector is a pivotal component responsible for delivering precise amounts of fuel into the combustion chamber. The 3944698 Tube Brace supports the Injector by providing a stable mounting point, ensuring that the Injector remains securely in place during engine operation. This stability is vital for maintaining the accuracy of fuel delivery, which directly influences engine performance and fuel efficiency 4.

Support for Injector Fuel Supply Tube

The Injector Fuel Supply Tube is responsible for transporting fuel from the fuel rail to the Injector. The 3944698 Tube Brace plays a significant role in maintaining the alignment and integrity of the Injector Fuel Supply Tube. By securing the tube in its correct position, the Tube Brace helps prevent leaks and ensures a consistent fuel supply to the Injector. This consistent fuel delivery is essential for optimal combustion and overall engine efficiency 5.

Enhanced System Reliability

By supporting both the Injector and Injector Fuel Supply Tube, the 3944698 Tube Brace contributes to the reliability and durability of the engine system. Its role in maintaining component alignment and stability helps reduce the risk of mechanical failures and ensures that the engine operates smoothly under various conditions.

Conclusion

The 3944698 Tube Brace by Cummins is a critical component for enhancing the structural integrity and performance of commercial trucks and engines. Its robust design, precise fitment, and essential role in supporting key engine components make it a valuable addition to any heavy-duty vehicle. Regular maintenance and timely replacement of this part are crucial to ensure the longevity and reliability of the truck’s chassis and engine system.

-

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Goodnight, Nicholas, and Kirk Van Gelder. Automotive Braking Systems. Jones & Bartlett Learning, 2018.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 3666013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.