This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 101208 Safety Control Bracket is a component designed to enhance the operational safety of commercial trucks. It plays a role in the truck’s safety systems by ensuring that various safety mechanisms function correctly under different operating conditions. This bracket contributes to the overall safety and reliability of commercial vehicles, protecting both the driver and the cargo 1.

Purpose and Function

The 101208 Safety Control Bracket secures and supports critical safety components within the vehicle’s safety systems. It facilitates the interaction between these components and the truck’s control mechanisms, ensuring that safety features are correctly positioned and operational. This contributes to the truck’s ability to respond effectively to various driving conditions and potential hazards 2.

Key Features

The primary features of the 101208 Safety Control Bracket include its robust design and the use of high-quality materials, which enhance its performance and durability. The bracket is engineered to withstand the rigors of commercial truck operation, providing a stable and secure mounting solution for safety components. Its design allows for easy installation and integration within the truck’s system, ensuring that it can be effectively utilized across a range of truck models 3.

Benefits

The advantages provided by the 101208 Safety Control Bracket include improved safety through secure mounting of safety components, enhanced performance by ensuring these components operate within their designed parameters, and potential cost savings for fleet operators due to its durability and reliability. By maintaining the integrity of the truck’s safety systems, this bracket contributes to reducing the risk of accidents and the associated costs 4.

Installation and Integration

Proper installation of the 101208 Safety Control Bracket involves ensuring that it is correctly aligned and secured within the truck’s system. This process may require specific preparations, such as cleaning the mounting area and verifying that all necessary components are in place. Careful attention to these details ensures that the bracket functions as intended, contributing to the overall safety and performance of the truck 5.

Maintenance and Troubleshooting

Maintaining the 101208 Safety Control Bracket is crucial for ensuring its optimal performance. Regular inspections should be conducted to check for any signs of wear or damage, and any issues should be addressed promptly. Troubleshooting common issues may involve verifying the bracket’s securement, checking for proper alignment, and ensuring that all connected components are functioning correctly. These practices help to maintain the bracket’s effectiveness over time 6.

Regulatory Compliance

The 101208 Safety Control Bracket is designed to meet industry safety and performance criteria, adhering to relevant regulatory standards. This compliance ensures that the bracket contributes to the truck’s overall safety and reliability, meeting the expectations of both operators and regulatory bodies. By incorporating this bracket into their vehicles, fleet operators can ensure they are operating within the bounds of safety regulations 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The company’s commitment to excellence is evident in its wide range of products, including the 101208 Safety Control Bracket, which exemplifies Cummins’ dedication to enhancing the safety and performance of commercial vehicles 8.

Role of Part 101208 Safety Control Bracket in Engine Systems

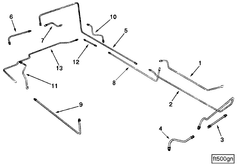

The 101208 Safety Control Bracket is an integral component in ensuring the secure and efficient operation of various engine systems. It plays a significant role in the integration and stabilization of several key components, including the Fuel Drain Tube, Throttle Control, and Tube Fuel Drain.

Integration with Fuel Drain Tube

The Fuel Drain Tube is responsible for safely directing excess or unwanted fuel away from the engine system. The 101208 Safety Control Bracket secures the Fuel Drain Tube in place, preventing any undue movement that could lead to leaks or inefficient fuel drainage. This bracket ensures that the tube remains aligned with other components, maintaining a consistent and reliable fuel management system 9.

Stabilization of Throttle Control

The Throttle Control is a pivotal component that regulates the amount of fuel and air mixture entering the engine, directly influencing the engine’s performance. The 101208 Safety Control Bracket provides a stable mounting point for the Throttle Control, ensuring that it operates within the precise parameters required for optimal engine function. This stability is essential for maintaining consistent throttle response and preventing any unintended acceleration or deceleration 10.

Secure Attachment of Tube Fuel Drain

The Tube Fuel Drain is another component that benefits from the secure attachment provided by the 101208 Safety Control Bracket. By firmly holding the Tube Fuel Drain in position, the bracket helps to prevent any potential disconnections or misalignments that could compromise the fuel system’s integrity. This secure attachment is vital for maintaining a leak-free and efficient fuel drainage process 11.

Conclusion

In summary, the 101208 Safety Control Bracket enhances the reliability and performance of engine systems by providing a stable and secure foundation for critical components such as the Fuel Drain Tube, Throttle Control, and Tube Fuel Drain. Its robust design, ease of installation, and compliance with regulatory standards make it a valuable component for ensuring the safety and efficiency of commercial trucks.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSX15 CM2250 X115, Bulletin Number 4388741.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSX15 CM2250 X115, Bulletin Number 4388741.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Peters, G., & Peters, B. J. (2002). Automobile Vehicle Safety. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.