This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

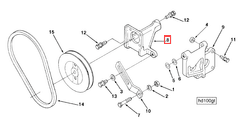

The Barnes Pump Bracket, identified by part number 128745, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This Cummins part plays a significant role in the operation of heavy-duty trucks, particularly in relation to the fuel system. Understanding its function and importance can contribute to better maintenance practices and overall vehicle performance.

Purpose and Function

The Barnes Pump Bracket serves as a mounting solution for fuel pumps within the truck’s fuel system. It facilitates the secure attachment of the fuel pump to the vehicle’s frame, ensuring stability and proper alignment. This bracket contributes to efficient fuel delivery by maintaining the pump’s position and allowing for optimal operation within the fuel system. Its integration is vital for the consistent and reliable performance of the fuel pump 1.

Key Features

The design and construction of the Barnes Pump Bracket are tailored for durability and performance. Crafted from high-strength materials, it is built to withstand the rigors of heavy-duty truck operations. The bracket offers versatile mounting options, accommodating various fuel pump models and truck configurations. Its design includes features that enhance performance and longevity, such as corrosion-resistant coatings and precise engineering to ensure a secure fit 2.

Benefits

Incorporating the Barnes Pump Bracket into a truck’s fuel system offers several advantages. It contributes to improved fuel system reliability by ensuring the fuel pump remains securely in place and properly aligned. The bracket’s design facilitates ease of installation, reducing downtime during maintenance or replacement procedures. Additionally, its compatibility with a wide range of truck models makes it a versatile choice for fleet managers and technicians 3.

Installation Process

Installing the Barnes Pump Bracket requires attention to detail to ensure proper alignment and secure attachment. The process involves selecting the appropriate mounting location on the truck’s frame, using the provided hardware to attach the bracket, and then securing the fuel pump to the bracket. It is important to follow manufacturer guidelines for torque specifications and alignment to ensure the bracket and pump operate efficiently. Tools required may include a torque wrench and socket set 4.

Maintenance and Troubleshooting

Regular maintenance of the Barnes Pump Bracket is key to ensuring optimal performance and longevity. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the bracket and its mounting area can prevent buildup that might affect performance. Troubleshooting common issues, such as leaks or misalignment, often involves checking the bracket’s attachment points and the condition of the fuel pump. Addressing these issues promptly can prevent more significant problems down the line 5.

Common Issues and Solutions

Frequent problems associated with the Barnes Pump Bracket may include leaks at the fuel pump connection or mounting issues due to corrosion or wear. Solutions typically involve inspecting the bracket and fuel pump for damage, ensuring all connections are tight, and replacing any worn or corroded components. Preventive measures, such as applying corrosion-resistant coatings and regular inspections, can help mitigate these issues 6.

Cummins Overview

Cummins, the manufacturer of the Barnes Pump Bracket, is a renowned entity in the automotive industry with a rich history of innovation and quality. Established in 1919, Cummins has grown to become a global leader in diesel engine manufacturing, with a diverse product portfolio that includes engines, filtration systems, and aftermarket parts. The company’s commitment to quality and performance is evident in its wide range of products, including the Barnes Pump Bracket, which benefits from Cummins’ expertise in engineering and manufacturing excellence 7.

Role of Part 128745 Barnes Pump Bracket in Engine Systems

The integration of Part 128745 Barnes Pump Bracket within engine systems is essential for the optimal operation of several key components. This bracket serves as a foundational element that ensures the secure and stable mounting of the hydraulic pump.

When installed, the Barnes Pump Bracket interfaces directly with the hydraulic pump mounting points, providing a robust connection that can withstand the dynamic forces generated during engine operation. This secure attachment is vital for maintaining the alignment and operational integrity of the hydraulic pump.

The hydraulic pump, once mounted using the Barnes Pump Bracket, plays a significant role in the drive system of the engine. It is responsible for generating the necessary hydraulic pressure to operate various engine components, such as actuators, valves, and other hydraulically driven mechanisms.

The stability provided by the Barnes Pump Bracket ensures that the hydraulic pump can deliver consistent performance without the risk of misalignment or movement, which could lead to inefficiencies or failures in the hydraulic system.

Conclusion

In summary, the Barnes Pump Bracket is a key component in the assembly and functionality of the hydraulic pump within engine systems, ensuring that the pump is securely mounted and capable of performing its role effectively within the drive system. Its robust design and precise engineering contribute to the overall efficiency and longevity of the engine, making it a vital component in the engine’s ecosystem.

-

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ -

Automotive Heating Ventilation and Air Conditioning, Quansheng Zhan, Shengbo Eben, Li Kun Deng, Jones Bartlett Learning, 2018

↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif Ed, Springer Vieweg, 2014

↩ -

Entire Vehicle: Second Edition, Michael Hilgers, Springer Nature, 2023

↩ -

Engine: M11 (STC, CELECT™, CELECT Plus™ Models), Bulletin Number 3666139, Troubleshooting and Repair Manual

↩ -

Automotive Lubricants Reference Book, Arthur J Caines, Roger F Haycock and John E Hillier, SAE International, 2004

↩ -

Entire Vehicle: Second Edition, Michael Hilgers, Springer Nature, 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.