This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

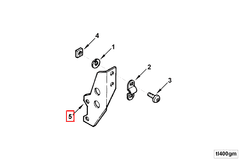

The Cummins Control Linkage Bracket, part number 157231, is a component designed for use in heavy-duty truck operations. Cummins, a well-established name in the automotive industry, produces a range of parts and engines known for their reliability and performance. This part is integral to the truck’s control system, ensuring efficient and reliable operation of the vehicle.

Function and Operation

This Cummins part plays a role in the truck’s control system by connecting and supporting various components. It acts as a mounting point for linkages that control the engine’s throttle, transmission, and other critical systems. By providing a stable and secure connection, the bracket ensures that these linkages operate smoothly and accurately, which is vital for the overall performance and drivability of the truck.

Key Features

The Control Linkage Bracket 157231 is characterized by its robust design and high-quality materials. It is engineered with precision to ensure a perfect fit and optimal performance. The bracket is made from durable materials that can withstand the rigors of heavy-duty truck operations, including exposure to vibrations, extreme temperatures, and mechanical stress. Its design is tailored to be compatible with Cummins engines, ensuring seamless integration and reliable operation.

Benefits

This part offers several advantages. It contributes to improved reliability of the control system by providing a stable and secure mounting point for critical linkages. This enhances the overall performance of the truck, ensuring smoother operation and better responsiveness. Additionally, the bracket’s design facilitates easier maintenance, allowing for quick and straightforward replacement or adjustment when necessary.

Installation Process

Installing the Control Linkage Bracket 157231 requires careful attention to detail. Begin by ensuring the truck is parked on a level surface and the engine is turned off. Gather the necessary tools, which may include wrenches, sockets, and possibly a torque wrench. Remove the old bracket if replacing, taking note of the linkage positions. Align the new bracket with the mounting points and secure it in place using the appropriate fasteners. Reattach the linkages, ensuring they are properly aligned and tightened to the manufacturer’s specifications. Finally, perform a thorough inspection to confirm that all connections are secure and the linkages operate smoothly.

Common Issues and Troubleshooting

Typical problems associated with the Control Linkage Bracket 157231 may include loose connections, worn fasteners, or damaged linkages. If the truck exhibits unusual noises, difficulty in shifting gears, or inconsistent throttle response, these could be indicative of issues with the bracket or its connections. Diagnostic steps involve inspecting the bracket and linkages for signs of wear or damage, ensuring all fasteners are tight, and verifying that the linkages are properly aligned. Potential solutions may include tightening or replacing fasteners, adjusting linkages, or replacing the bracket if it is damaged.

Maintenance Tips

Regular maintenance of the Control Linkage Bracket 157231 is key to ensuring its longevity and optimal performance. Inspect the bracket and its connections during routine maintenance checks. Look for signs of wear, corrosion, or damage. Ensure that all fasteners are tight and that the linkages are properly aligned and free from obstructions. Lubricating the linkages and pivot points can also help maintain smooth operation. Addressing any issues promptly can prevent more significant problems down the line.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. Founded in 1919, Cummins has built a reputation for innovation, quality, and reliability. The company serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. Cummins’ product range includes engines for on-highway and off-highway applications, as well as components that support these engines. The company is committed to sustainability and reducing the environmental impact of its products and operations. 1

Cummins Control Linkage Bracket 157231 Compatibility

The Cummins Control Linkage Bracket, part number 157231, is a critical component designed to ensure the proper functioning of engine control systems. This bracket is engineered to fit seamlessly with various Cummins engine models, providing stability and alignment for the control linkage mechanism.

K19 Engine Series

In the K19 engine series, the Control Linkage Bracket 157231 plays a pivotal role in maintaining the integrity of the engine’s control linkage system. This bracket is meticulously crafted to interface with the specific design and layout of the K19 engine, ensuring that the linkage operates smoothly and efficiently. Its robust construction and precise fitment are essential for the reliable performance of the engine, particularly in demanding applications where precision and durability are paramount.

The compatibility of the Control Linkage Bracket 157231 extends to other Cummins engines, ensuring that it can be utilized across a range of models. This versatility is a testament to Cummins’ commitment to providing high-quality, interchangeable parts that meet the rigorous demands of modern engine technology. 2

Understanding the Integration of Part 157231 Control Linkage Bracket in Engine Systems

The Part 157231 Control Linkage Bracket is an essential component in the orchestration of various engine systems, ensuring seamless operation and precise control. This bracket plays a significant role in the assembly and functionality of several key components.

Throttle Control System

In the throttle control system, the Control Linkage Bracket securely mounts the throttle control mechanism. It provides a stable connection point for the throttle linkage, which is responsible for modulating the airflow into the engine. This bracket ensures that the throttle control operates smoothly, allowing for accurate adjustments of engine speed and power output.

Coupling with Fuel Pump

The bracket also interfaces with the fuel pump system. By providing a mounting point for the fuel pump linkage, it ensures that the fuel delivery is synchronized with the throttle position. This integration is vital for maintaining the correct air-fuel ratio, which is essential for efficient combustion and optimal engine performance.

Vernier Throttle Integration

For engines equipped with a vernier throttle, the Control Linkage Bracket is instrumental in fine-tuning the throttle settings. It allows for precise adjustments through the vernier throttle mechanism, enabling the operator to make minor tweaks to the engine’s performance. This level of control is particularly important in applications where exact throttle settings are required, such as in aviation or high-performance automotive engines.

Overall Engine Mounting

Beyond specific components, the Control Linkage Bracket contributes to the overall structural integrity of the engine mounting system. It helps in securing various linkages and control mechanisms, ensuring that they remain in proper alignment and function correctly under varying operational conditions. This stability is essential for the longevity and reliability of the engine system.

Conclusion

In summary, the Part 157231 Control Linkage Bracket is a foundational element in the engine’s control and linkage systems. Its role in mounting, coupling, and ensuring the precise operation of components like the throttle control, fuel pump, and vernier throttle cannot be overstated. Regular maintenance and proper installation are crucial to maximizing the performance and reliability of this part in heavy-duty truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.